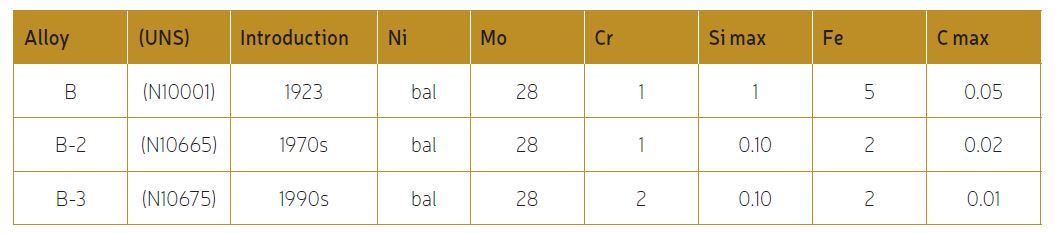

Prior to the introduction of the workhorse C-family of nickel-base alloys (Ni-Cr-Mo) in the early 1930s, work had been conducted on nickel-molybdenum alloy compositions. This resulted in the award of a patent, in 1921, for a nickel-molybdenum alloy composition range, which ultimately led to the introduction of Alloy B (Ni-Mo) in 1923 with a nickel content of 60% and nearly 30% molybdenum.

By Geir Moe, Nickel Institute

B-type alloys possess exceptional resistance to reducing acids, such as hydrochloric, sulphuric, acetic, and phosphoric. Unfortunately, B-type alloys have poor corrosion resistance to oxidising environments. Hence, they are not recommended for use in oxidising media or in the presence of ferric or cupric salts which may cause rapid premature corrosion failure. These salts may develop when hydrochloric acid comes in contact with iron and copper.

Prior to the Second World War, Alloy B was used in supercharger turbine blades in aircraft engines to boost performance and increase horsepower. This application was eventually replaced by other superalloys.

Alloy B-2, introduced in the 1970s, was a modification of the original B composition. It featured reduced silicon and carbon content, to improve thermal stability and resist the formation of grain boundary carbides. This improvement in corrosion resistance was particularly beneficial in the heat-affected zone after welding.

The composition was additionally optimised in Type B-3 to further enhance thermal stability and fabrication characteristics and resistance to stress corrosion cracking. Molybdenum primarily provides the corrosion resistance to acidic reducing environments, but it is the nickel-base that provides the foundation for an engineering alloy that can be easily fabricated and welded into industrially useful equipment.

About Nickel Institute

The Nickel Institute is the global association of leading primary nickel producers. Its mission is to advocate for the responsible supply and sustainable development of nickel and the nickel industry. For information, visit nickelinstitute.org

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in February 2024. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.