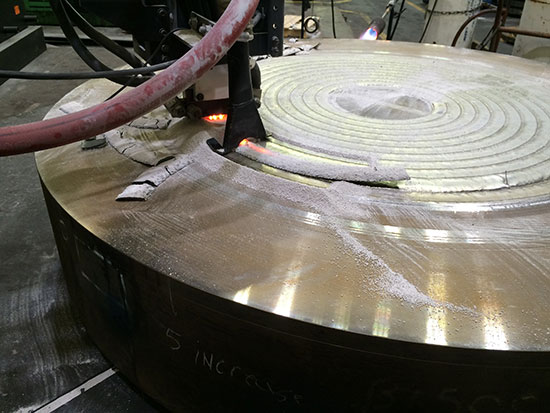

Alloy double helix helical bundle in fabrication.

When thinking about heat exchangers, the name Brask, Inc. may come to mind – and not without reason. As a leader in the design, manufacturing, and repair of shell and tube heat exchangers, and various other related petrochemical equipment, Brask and its team of stellar engineers provide custom solutions and 24/7 service to its dedicated customer base. Heat Exchanger World magazine had the privilege of sitting down with Mr. Bal K. Sareen, President of Brask, Inc, at the 2021 Heat Exchanger World Conference and Expo in Pasadena, Texas, to discuss the company’s history, products, and ongoing dedication to customer satisfaction.

By Sarah Do Couto and Sara Mathov, Heat Exchanger World Americas

History at a glance

It was the year 1999, and Mr. Sareen – an already well-established figure in several manufacturing sectors – was looking to do something different. Rather than focusing on his existing projects, he purchased Industrial Equipment and Engineering (IEE), an American company that served midstream, and upstream oil and gas customers. Mr. Sareen and his team decided to expand IEE’s offerings to serve downstream industries and specialized in process equipment, namely the design, manufacturing, and repair of shell and tube heat exchangers.

Now widely recognized under the name Brask, the business specializes in the design and fabrication of shell and tube heat exchangers, including complete exchangers, replacement parts, ASME Code modifications, new bundles, strip and retubes, turnaround repairs along with consulting services. With two state of the art facilities, the IEE Facility, which was built in 2003 and has weld overlay and nozzle profile capabilities and a cleanroom, and the Neela Facility, which was constructed in 2011 handles a high volume of off site service and fabrication of replacement parts including automatic tube sheet welding processes, the company has grown as a go-to source in the industry.

Brask inc. is an ASME code approved shop holding U, S and R stamps, and has fabricated heat exchangers up to 4” thick, machined components up to 13” thick and tube lengths of 60’-0” long, with expertise in fabrication using carbon steel, low alloy steels (1 ¼ Cr, 2 1/4 Cr, 5 Cr and 9 Cr), stainless steels, duplex stainless steels, copper alloys, nickel, nickel alloys and titanium.

“We are proud to say that we strive to be known as ‘The heat exchanger people’,” explained Mr. Sareen. “Just like Kleenex comes to mind when someone needs a clean tissue paper, we want to create a reputation in the market where when you think of heat exchanger, the first name that pops up is Brask, Inc.”

The majority of Brask, Inc. customers are involved in the petrochemical sector, however the company is dedicated to serving all clients regardless of industry. “Our goal is to provide high quality service at reasonable prices, while offering a dependable product,” said Mr. Sareen. “The last thing you want is for the customer to have a surprise; no surprises is the best service you can provide.”

Achieving success

In addition to being a privately-owned business, there are several things that sets Brask, Inc. apart from its competitors. Dedication to the highest standard of quality, its skilled and knowledgeable workforce, the company’s lead times, and its ability to manage customer and vendor relationships are just a few of the qualities that make Brask a continually sought-after manufacturer.

Lead times

It is no secret that lead time is immensely important to customers and clients. “One of the most important things to note in our industry is that when the customer needs his product, he needs it fast,” said Mr. Sareen. “Anytime you can reduce the manufacturing time from point A to point B puts you ahead of the competition.”

“For example, when completing a project that required the creation of the holes, we used to have a nozzle burning in a shell, which would take close to 20 to 40 hours to complete. To address the length of time this process required, we bought a machine from Germany which does automatic burning of the hole and beveling of it; this allows us to profile a nozzle at the same time,” he explained. “As these holes are now cut with an automatic machine, their accuracy is much better, and the time – what used to take 20 to 40 hours – now takes 2 to 4 hours to do the same job. Not only have we improved the quality, we have also improved our speed.”

Mr. Sareen also cited a similar situation involving Brask, Inc.’s cladding of tube sheets. “We used to be able to do 3 to 4 pounds an hour. Now with our continuous investments in new machines, we can do 23 pounds an hour; what used to take us a week to do, now we can do it in two shifts. We are always looking at our manufacturing processes to reduce the lead time and run time.”

Standard of quality

Quality is of the utmost importance to Brask, Inc. Often, this means vigorous testing and inspection of all company products to ensure they are up to standard.

“We make sure that the individuals who are preforming our inspections are highly trained, skilled professionals. It is very important that before the product is turned out of our shop, it meets our standards,” explained Mr. Sareen. “It has our quality stamp on it, and it is not something we take lightly. Our employees take pride in what they are doing to make sure we put out a good product.” The high quality of Brask, Inc.’s products can easily be attributed to the company’s very skilled and dynamic team of engineers. “Although we have the state of the art vessel manufacturing facility, it is not the equipment that sets us apart from our competition, it is the team. We have the best, most motivated, and highly educated team of 24 engineers.” Brask, Inc. also places heavy focus on ensuring all of its facilities provide safe and hazard-free work environments for its staff, allowing them to complete processes on time and to the highest standard.

Fostering good relationships

While some companies are focused entirely on maintaining exceptional client relationships, Brask, Inc. is also dedicated to nurturing all of its relationships, be that customer, vendor, or otherwise.

“We are in the center of the entire process. On one side there is the customer, and on the other side the vendor, and some companies have a habit of paying more attention to the customer,” said Mr. Sareen. “Without vendors, we cannot service the customer. So to us, the vendor is as important as the customer is.” The company has gone so far as to host events connecting both its customers and vendors together, which helps facilitate a stronger brand dedication and collaboration.

Brask, Inc. knows the importance of listening to its customer base first and foremost. By listening to the customers it is able to change and grow with them, which provides them with the ability to anticipate future needs and address potential issues before they come to fruition. “We are always looking at the challenges our customer is facing, and we are not afraid to throw in R&D dollars on it,” stated Mr. Sareen. “We pride ourselves on our ability to implement new technologies and new product lines that are of interest to our clients. We listen to the client. When one of our customers requested that we get gain expertise in doing transfer exchanges, we listened. We collaborated with the original manufacturer, and today we have signed a cooperation agreement with that company to be the only company in the United States to service their products.”

When it comes to heat exchangers, Mr. Sareen joked that Brask, Inc. is a “cradle to the grave” company. “We want to help our customers with everything from front-end design, expansion, fabrication, design, and then even post-fabrication. We will also assist with failure analysis, if the customer needs,” he said. “Our mode of operation is to let the customer tell us what they want, and we provide them with the information they need so they do not have to worry about writing separate purchase orders and requisitions.”

Looking forward: The future of Brask, Inc.

While it has many areas that it excels at which will helps it maintain its role as a progressive industry leader, the future of Brask, Inc. lays in R&D. “Without research and development, you are stuck with yesterday’s technology. If you are not moving, you are dead,” he said. “You have to listen to the voice of customer, and look at what the competition is doing.”

Brask, Inc. is also currently searching for ways to further improve its automation processes. “We are always seeking out better solutions to automate our process. One way we do this is by looking and listening to our equipment suppliers that provide solutions,” said Mr. Sareen. “With what is going on with the carbon taxes and green energy, we do not know where we could be in 10 years, and we are constantly looking at and being challenged as to what changes we have to make to stay in business. We are in tune with what needs to be done to transition to green energy. We will adapt.” With a dedication to its customer-first mentality, Brask’s primary goal is to satisfy the customer on every job.

About this Featured Story

This Featured Story was first published in the March 2022 issue of Heat Exchanger World Magazine. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.