ETEKINA HPHE at Fagor Ederlan Aluminium Casting Foundry in Spain

Each year industries across Europe allow a valuable source of heat energy to simply escape through their chimneys. An EU-funded project called ETEKINA has reimagined a decades-old technology called ‘heat pipe heat exchangers’ that allow companies to re-use the heat they generate.

All text and images courtesy of ETEKINA consortium

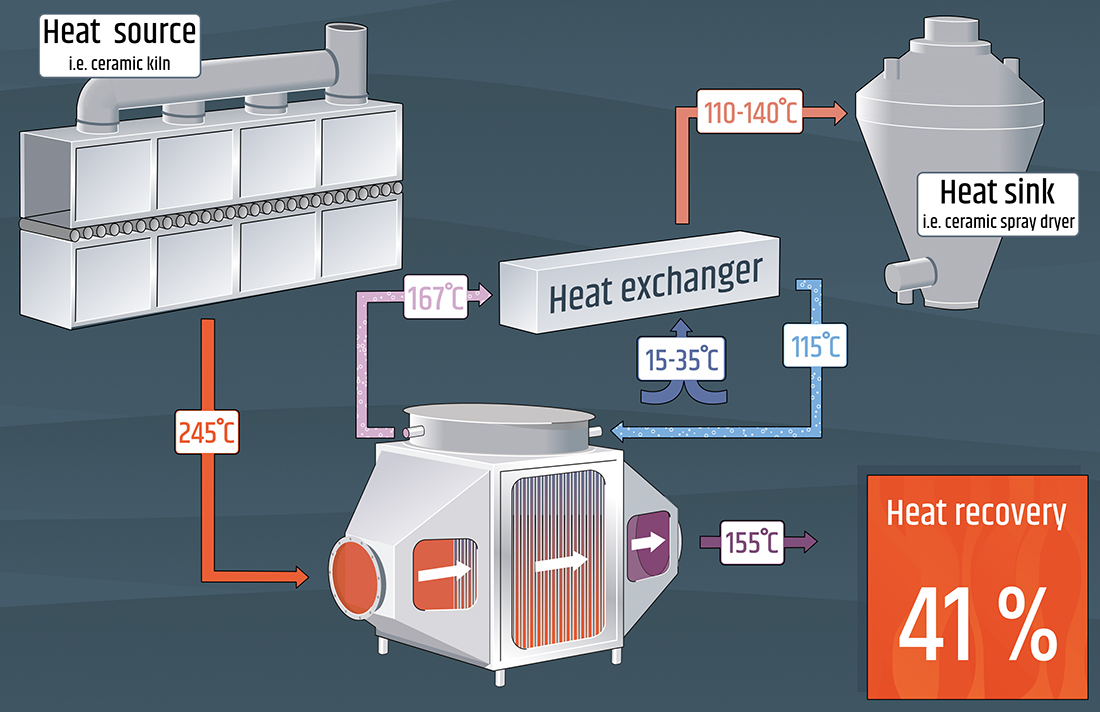

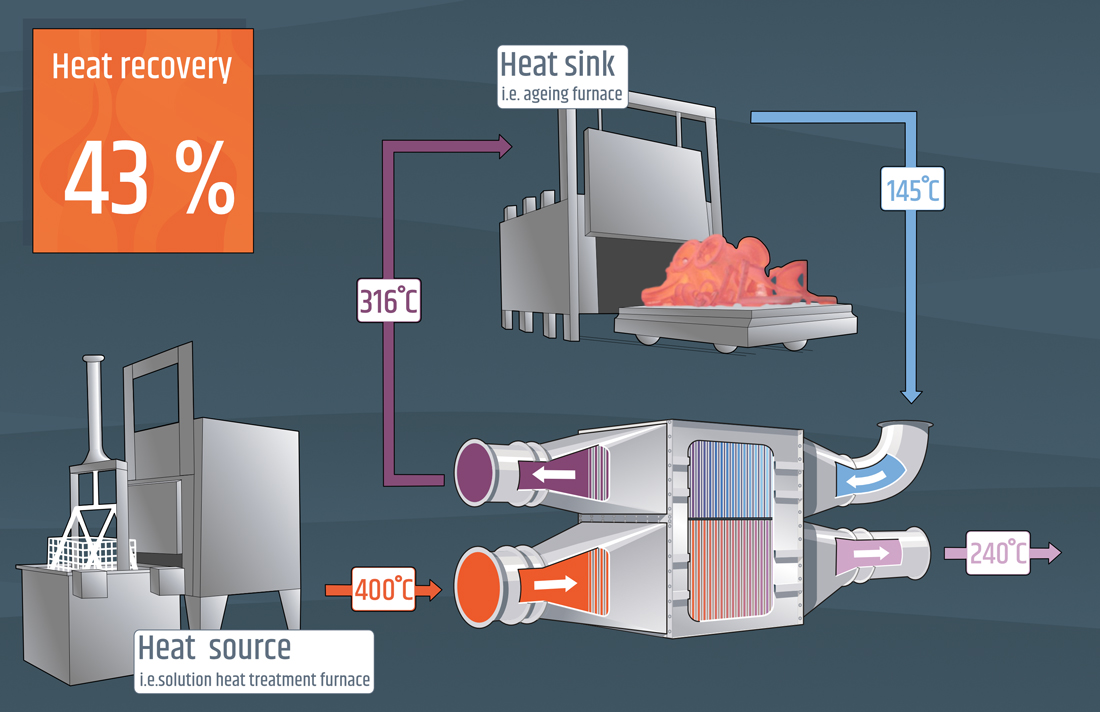

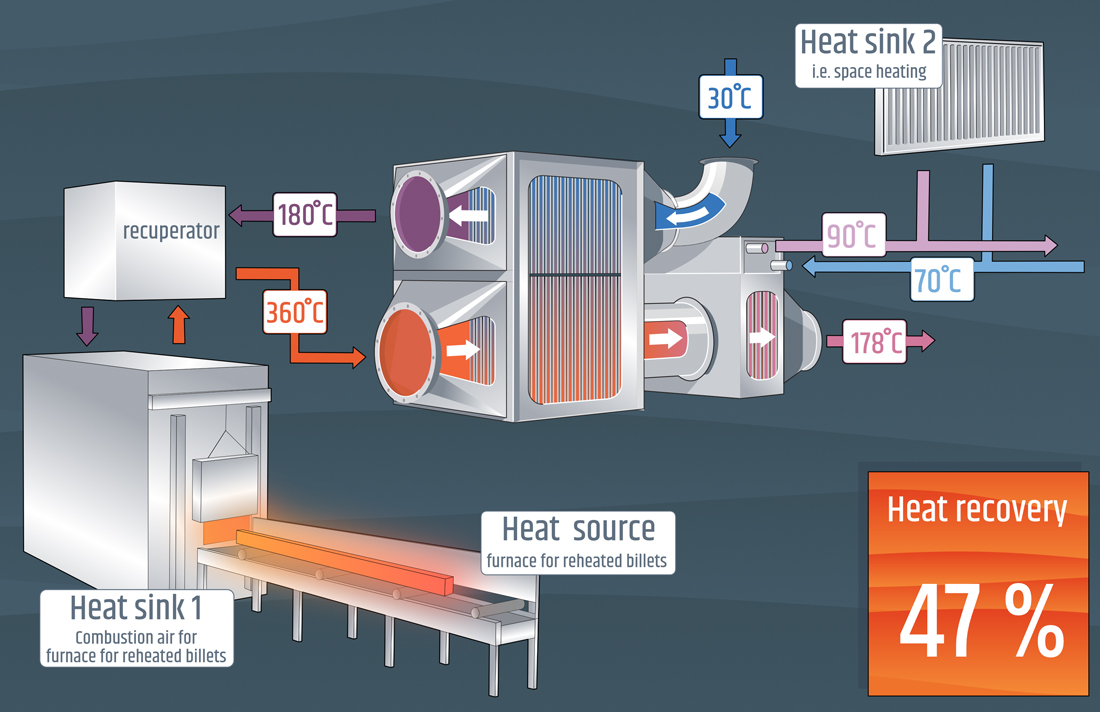

So far three sites that installed the prototype technology have slashed their fuel costs by 40% – an aluminium casting production plant in Spain (Fagor Ederlan), a steelworks in Slovenia (SIJ Metal Ravne) and a ceramic producer in Italy (Atlas Concorde).

Hussam Jouhara, a professor of Thermal Engineering at Brunel University London, is the technical coordinator of the project and shared his thoughts about the project in this interview conducted by ESCI.

Professor Jouhara, you and the team in the ETEKINA project have found a way to add a new type of heat exchanger to recover heat from one industrial process and reuse it in another part of the factory. What’s at the core of this technology?

A heat pipe is a thermal superconductor. The key is that you don’t need to force a fluid using pumps or fluid piping between the hot region and the cold region. The heat pipe itself can do that in a passive manner as long as you allow it access to the hot stream and the cold stream under the correct heat transfer conditions.

When you look at the system from the outside, it looks rather simple. Tubes come in between two chambers, and these tubes are just absorbing the heat and delivering it to where it is required. But if you look deeper inside each tube, you have a very complex science. You’re dealing with two phase heat transfer – liquid changing its phase from liquid to vapour and in the process carrying the latent heat to deliver it to the condenser section, which then heats the heating fluid.

Can you give some examples about the different liquids you may be using or the different materials?

In the ETEKINA project we used two fluids inside those heat pipes. One fluid is just pure water. But when we have high temperature applications, we also have fluids that are capable of being used effectively inside the heat exchanger itself to make the heat pipes. As these fluids are confined inside the system, there is only a small amount of them inside.

The ETEKINA project started four years ago. What was your intention for the project? What started you on this idea?

The idea of putting the ETEKINA project together was really just to show off the heat pipe technology and how it can be used to recover waste heat from very challenging streams that other conventional systems couldn’t manage to recover and reuse the heat that is being recovered in the plant itself. This then leads to reducing the plant’s carbon footprint and reducing the energy demand and enhancing the plant energy efficiency in general.

I think that ETEKINA is contributing by enhancing the efficiency of these systems, using the right technology that will facilitate that. The target for ETEKINA was 40 percent recovery of the available heat that is being wasted from the exhaust streams. I am pleased to say that after four years and having installed the three units, the consortium managed to get the 40 percent as the minimum.

We are actually above that in all three demo cases. This is something that is a pleasure to report, and it is a success for the whole consortium.

Here is a critical question – why is it that it’s only now that we have been able to design, build and implement this heat pipe technology? The principle is around forty years old.

You need to have a proper understanding of the chemistry. You need to understand the material science. You need to have proper understanding of the business case to ensure this is something that will make a proper business sense to any company that will adopt it. You also have to understand very complex heat transfer phenomena; mainly two-phase transfer, two phase flow, complex terms. You need to combine the knowledge of all of these to comprehend the requirements for the design.

And it’s been a real pleasure working closely with a company in Wales in the UK to develop the capabilities of manufacturing those heat pipes. We design the manufacturing process and installation together.

Can you give some examples of what you mentioned the heat pipe technology will be dealing with, for example the steel case? Do you know what kind of temperatures we are dealing with? What is the situation in a steel furnace?

We have a demo case in Italy – the Ceramic producer Atlas Concorde – and the requirement is to provide high pressure hot water up to a hundred and seventy degrees for use in the process itself in various areas. And this water will be heated using the waste heat that we recovered from our heat exchanger.

The unique feature about the heat exchanger we built was that the exhaust stream is running through a section which is at near atmospheric pressure. So, there is no real investment that you need for high pressure equipment on the exhaust stream, which makes the system cost effective.

The steel works in Slovenia have requirements for heat sinks. The heat sinks are the fluids that are being heated from the heat that is recovered. So, in Slovenia, the unit there had two sections. The first section recovers the heat from a high temperature exhaust coming in, and this heat has direct use in preheating air that is used in the combustion chamber, which will directly lead to reduction in the fuel that is being used to give them the temperature they require in the process. This exhaust will leave that section with enough energy also that can be recovered to heat water to 90 degrees. The company is not only reusing the heat, they recover it. It also exporting energy to the wider area, making it more integrated with the community.

As for the Aluminium alloy production line Fagor Ederlan in Spain, which is the unit in one of our partners facilities, that unit is dealing with very high temperatures. High temperatures that usually require very complex designs and a very iterative approach to ensure that under any circumstances you don’t have any cross-contamination between the two streams, and you manage the high temperature to give the process high temperature heats and fluid to that they can use in the process. It is something that we actually managed in ETEKINA in a cost-effective way and successfully installed the unit.

Each of the units that we delivered in this project dealt with a complex and challenging exhaust stream in a specific way. That’s what is so unique about the heat pipe technology. It can deliver solutions to complex scenarios.

Also, from an investor point of view you have amazing numbers.

In this project it’s not only an academic challenge. It is an applied project. We had to deliver a system with a return on investment within 24 months or less. Otherwise, we can’t convince the wider industry to adopt it. Therefore, as you said, the business case for the units was rather amazing, and the validation came from the data that we collected so far. We are achieving our goal if these units are to be installed or designed for a similar process anywhere in Europe or worldwide.

No time like the present

In early February this year, the cost of carbon reached record highs with figures for a ton of carbon dioxide emissions nudging EUR 95. Since this time, the pollution penalty set by the European Union’s Emissions Trading Systems has decreased but carbon costs remain tens of Euros higher than previous trading prices at a time when natural gas prices are also eye-wateringly high.

The implication for waste-heat recovery projects, such as ETEKINA, is profound. As Mark Boocock, managing director of Econotherm, UK, highlights: “Rising gas prices and higher carbon costs are significantly driving the demand for waste heat recovery, worldwide.”

“Energy projects that were struggling to get signed off in the past are now flying through and we’re also seeing a greater focus on environmental governance in many businesses,” he adds. “We’ve seen many global companies implement waste heat recovery in existing facilities whilst also mandating it in new facilities – this is a great time for projects such as ETEKINA.”

So, what’s next? Are we going to save the world with this technology?

Well, I’m hoping so. The thing is nowadays in Europe, if you think about our continent, the cost of emissions is extremely expensive. The interesting thing about this project is that halfway through ETEKINA and running some experiments in one of the sites, we realized that we could do even more things with this technology.

While working in this project and working with very capable partners, we unlocked another idea that we are now exploring under another project. And that project hopefully will save the world again because it will not only recover the wasted heat, but it will also recover wastewater.

And what kind of exploitation do you see for ETEKINA on a commercial level?

Now we have a technology that is at the right technology readiness level (TRL) that will enable the manufacturer in this case, Econotherm, to have much wider markets to deliver these units to industries at the right business case level. You can still see chimneys emitting vapours. It does tell you that there is something else that we can do, and there is something we can do to eliminate those chimneys and recycle everything in the plant itself, which is not a dream. It can be a reality with the right approach.

What kind of impact does ETEKINA have on academia?

We had the target of delivering new solutions for well-established, leading industries in their fields. But in parallel, we work together as universities and research institutes. For example, we have achieved new modelling capabilities. Usually, these modelling capabilities make for very expensive research. That is, if it is to be done in the lab, it would be extremely expensive to be able to do that research and using IT equipment. And we had these published.

These are now available to the wider research community everywhere in the world who have access to these articles. That makes the makes ETEKINA as useful to academia as it was useful for the industrial sector.

About the Project

ETEKINA is an EU funded research project that developed three heat pipe heat exchanger (HPHE) prototypes that can recover more than 40% of the waste heat streams in energy intensive industries. ETEKINA stands for “heat pipE TECHnologies for INdustrial Applications”. It started officially in October 2017 and ended in March 2022.

Find out more: www.etekina.eu

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in July 2022. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.