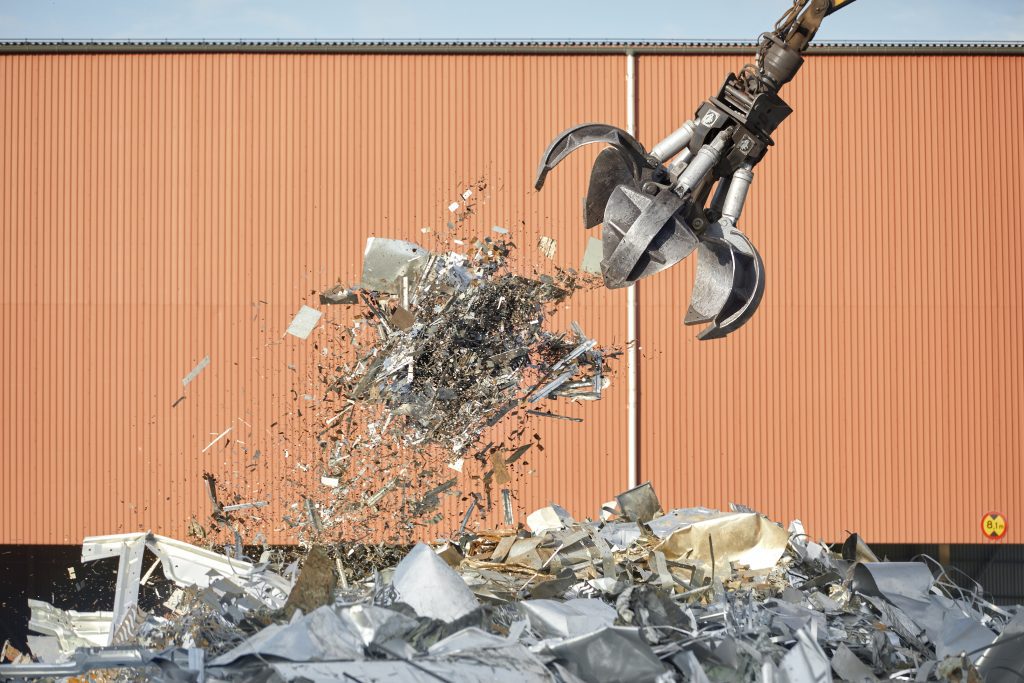

For over 100 years, Alleima has been reusing steel scrap as part of its production process. The company incorporates the use of electric arc furnaces, a low-carbon alternative to blast furnaces, and there is a strong focus on carbon footprint reduction throughout the whole organisation. Now, in a natural step towards an even more sustainable process, Alleima has begun analysing its products’ carbon footprint, from raw material to released product.

Text and images courtesy of Alleima

Climate change is an existential threat to the world. As rising carbon dioxide (CO2) emissions are at the heart of this threat, the EU has committed to achieving a climate-neutral society by 2050, and to a 55% reduction of greenhouse gas emissions by 2030, compared to 1990. One of the key ways in which industries and individual businesses can support these climate goals is to reduce the levels of carbon they emit.

For this reason, Alleima is implementing a Life Cycle Assessment (LCA) in order to quantify environmental impact and identify hotspots in a product’s life cycle. LCA will measure and calculate the carbon footprint of both materials and products over the cradle-to-gate lifecycle, covering greenhouse gas emissions from raw material extraction to product manufacturing. Customers will be provided with precise, third-party verified data available in the material certificate, which supports them on their own journeys to reduce environmental footprints. The LCA practices have been developed following ISO14067 (ISO14040/ISO14044) and verified by the IVL Swedish Environmental Research Institute.

“Before you can commit to

reducing a carbon footprint,

you first need to know where

it is coming from and what are

the biggest contributors.”

“Alleima strives to be transparent and report their LCA results and sustainability efforts to strengthen trust among customers and stakeholders. The collaboration with customers and implementation of sustainable solutions will contribute to making greener choices for the industry. It will also ensure that the company can remain competitive and meet customer demands. Sustainability is of crucial importance for the society around us, as well as for our customers, and LCA will be important for businesses in the future”, says Nicole Holmgren, LCA Specialist at Alleima.

Always striving

“Our products may not have names like ‘fossil-free steel’, but we have been working on these low-carbon products for many years, and making use of recycled materials,” Nicole continues. “It’s always been in the foundation of what we do. This Life Cycle Assessment project will not only highlight that, but also give us the chance to see where we need to do more.”

“We know that we have some really good suppliers with low carbon footprints, so we will be showing customers that our systems are reliable all the way through from the original source. But we’ll also be using LCA to find any remaining carbon hotspots in the lifecycle of our products, and uncover any processes that consume a lot of energy,” Nicole explains. “Before you can commit to reducing a carbon footprint, you first need to know where it is coming from and what are the biggest contributors.”

Next steps

To start with, Alleima will release LCA data for its rock drill steel products, supporting the sustainable shift in the mining industry. The next step involves expanding this approach across the entire production chain, verifying downstream products in the production flow. Each product will have a third-party verified carbon footprint added to the material certificate – like the information currently provided on recycled materials.

Alleima has reduced carbon emissions significantly through efficient processes, the use of fossil-free electricity and dedicated investments such as conversions to fossil-free fuels for heat treatment. The company is also already a signatory to several international principles and initiatives, including the United Nations’ sustainable development goals and the United Nations Global Compact. The principles form the basis of the company’s code of conduct and the code of conduct for suppliers.

In December 2022, Alleima decided to commit to set science-based net-zero targets, consistent with the Paris Agreement. By committing to the Science Based Targets initiatives (SBTi), Alleima is expanding the scope to its entire value chain and setting long-term net-zero targets.

Customer benefits

- Identifying hotspots within a product lifecycle allows for improvements, leading to a reduced environmental impact.

- Identifying opportunities for resource preservation by optimising use, and finding alternative materials that may be more sustainable.

- Potential cost savings by identifying and implementing more efficient processes.

- Sustainability and transparency strengthens relations with stakeholders, helping customers reach climate targets and providing a competitive advantage.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in December 2023. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.