Fouling, the unwanted accumulation of materials on surfaces, is a pervasive issue across numerous industries, significantly impacting efficiency and incurring substantial economic costs. MultiSonic’s SoundClean system offers an innovative solution by utilizing ultrasonic technology to prevent and eliminate fouling, thereby enhancing the lifespan and performance of heat exchangers and other critical equipment while also reducing environmental impact.

By Felix Wallner, Sales Director, Multi Sonic GmbH

The problem: Fouling

In the technical field, “fouling” means unwanted soiling in the form of deposits and growth on surfaces. Either raw materials contained in liquids are responsible for this – in water, for example, it would be salts and paraffin in crude oil – or material that was externally added, such as sludge, sand or organic substances. Particles eventually settle on the surface, thereby hindering the flow rate and the transfer of warmth and thus leading to reduced efficiency through the decreased performance of warmth transfer.

Fouling affects equipment in most industries, from the energy sector, paper manufacturing, and print production to the food industry and processing of mineral oil. Fouling in heat exchangers, machines and pipes is an underestimated phenomenon globally. It is estimated that performance losses through fouling contributes to economic damages amounting to approx. 0.25% of the gross domestic product of industrialized countries, which translates into losses of billions. Studies show that apart from the massive economic consequences, fouling could be responsible for 1 to 2.5% of worldwide carbon emissions in heat exchangers alone.

If the system’s output remains constant, additional energy is required to compensate for the decreased output. In case of further clogging of pipes, cleaning of the equipment is inevitable. For this process, large objects frequently must be dismantled and be laboriously cleaned pipe for pipe. This often interrupts production for several days and the use of chemicals and large amounts of water results in pollution of the environment and nature.

The solution: SoundClean system

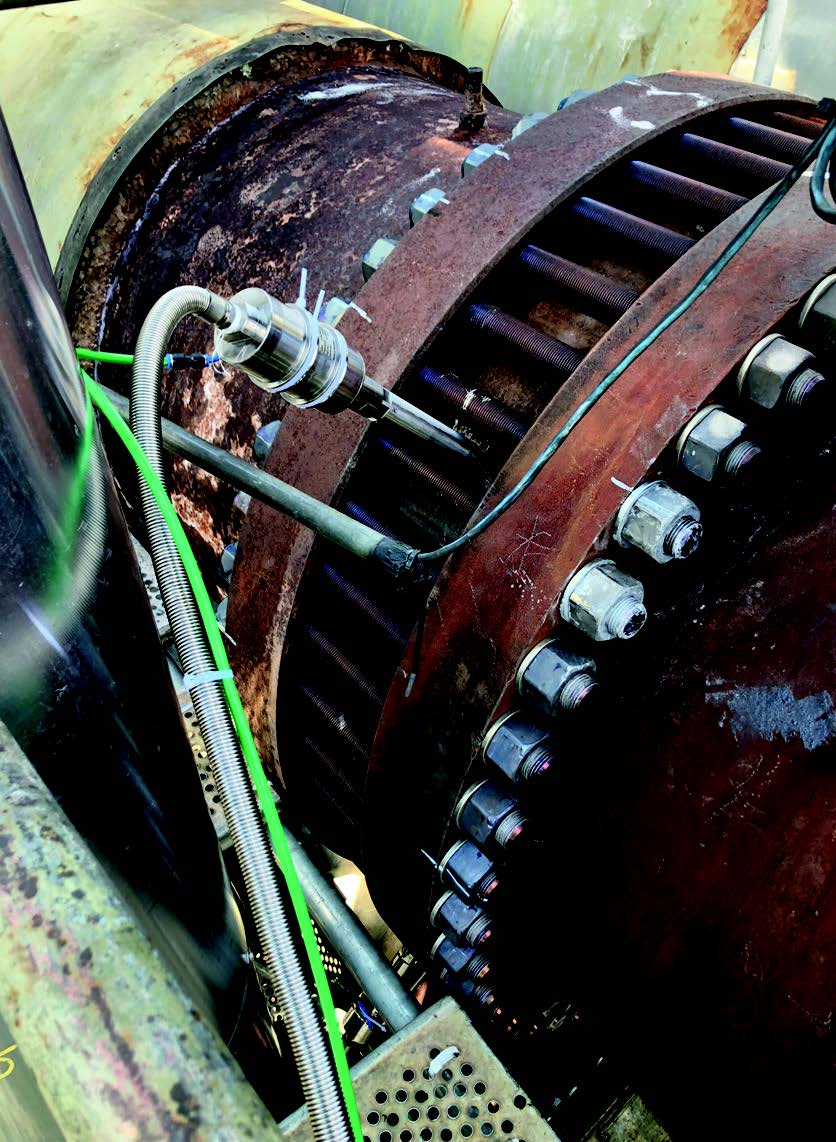

To extend the lifespan of heat exchangers, systems and pipes, MultiSonic developed the ultrasound system SoundClean, which reduces fouling of metallic materials or eliminates it completely. The system prevents deposits and growth on surfaces right from the start, prevents fouling in heat exchangers and pipes effectively and can be retrofitted easily and quickly.

The technology

Ultrasonic transducers are permanently attached to the solid body of metallic objects. The transducers create micro vibrations using ultrasound frequencies. The ultrasonic frequency is generated in pulses and vibrations occur in the micron range, i.e. thousandths of a millimetre, without damaging process equipment and weld seams or loosening screws.

Easy retrofitting with multiple benefits

SoundClean can be installed simply via Plug&Play on existing heat exchangers. After activation, the degree of efficiency of plants can be increased, whereby less heat energy and partly lower pump pressure are required for the same output. The lifespan is extended significantly and heat exchangers with SoundClean need to be cleaned less frequently, directly contributing to lower cleaning costs. Apart from that, the frequency and duration of interruptions of operations are reduced, which leads to an increase in profitability of plants. Finally, the system contributes positively to the environment, as less cleaning means less use of chemicals, water and energy.

About the author

In addition to his diploma studies in International Business Administration at the University of Innsbruck, Felix Wallner completed various internships and was self-employed in the field of information technology and data processing. After completing his studies, Felix Wallner started his career as a consultant at GCI Management in Munich in 2010. In 2010, he worked on his first project for MS Ultrasonic Technology in Spaichingen and is since then active in the field of Ultrasonics. From 2017 to 2021, he was responsible for building up component sales for ultrasonic welding machines in North America. In 2021, he joined Multi Sonic GmbH as Sales Director.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2024. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.