Ricoh Company, Ltd has developed a process to join aluminium parts fabricated by Binder Jetting (BJT) to wrought aluminium alloy. This new technique not only eases the restriction on the size of parts fabricated, but also has the potential to significantly reduce costs.

Metal Binder Jetting is a highly productive and low-cost Additive Manufacturing technology that can be used for prototyping and series manufacturing. However, because BJT requires sintering, it can be difficult to ensure accuracy when manufacturing very large parts.

Ricoh’s newly developed diffusion bonding technology for sintered materials fabricated by the BJT method solves the above issues. The company is using its proprietary liquid-phase sintering technology, which is useful in the fabrication of high-efficiency heat exchangers and other applications.

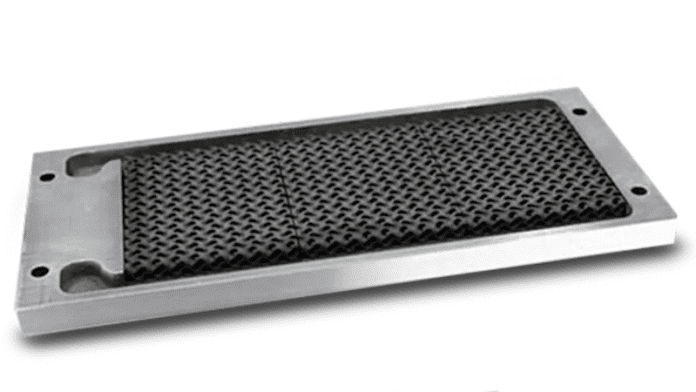

A heat exchanger consists mainly of fins that determine cooling performance and a case that determines the component’s dimensional accuracy. Ricoh’s idea is to use BJT to make fins of complex shapes and join them to an aluminium case prepared using an existing method. BJT’s ability to fabricate complex shapes allows for highly efficient cooling performance, while the machining accuracy of existing methods ensures the dimensional accuracy of the component.