In this case study we explore how Sovereign Air Movement optimized commercial ventilation efficiency using Heatex rotary heat exchangers. Faced with challenges such as high airflow demands, space constraints, and efficiency optimization, the company collaborated with Heatex to develop a cost-effective, energy-saving solution. The result was a highly efficient air handling unit that delivered substantial energy savings and a rapid return on investment.

Text & images by HEATEX

Sovereign Air Movement, a leading supplier of air handling units in the UK, specializes in designing and manufacturing efficient air handling solutions for commercial ventilation applications. Their dedicated team of design engineers utilizes advanced software to ensure that their air-handling equipment meets stringent environmental and engineering standards, such as the Energy-related Product (ErP) Directive and BS EN 1886:2007.

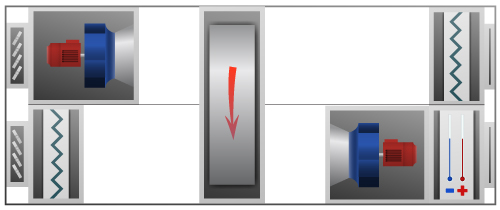

By providing a tailored, energy-efficient solution, Sovereign Air Movement ensures that each customer receives a bespoke system that meets their precise needs. A critical component of these systems is the air-to-air heat exchanger, which leverages the temperature differential between supply and exhaust air to improve overall efficiency, recover waste energy, and significantly reduce energy consumption.

To optimize their air handling units (AHUs), Sovereign Air Movement selected Heatex rotary heat exchangers due to their flexibility, efficiency, and ability to be customized to fit specific performance criteria. This decision was driven by Heatex’s ability to provide a wide range of design variables and options, ensuring an ideal fit for every AHU requirement.

General problems in commercial ventilation systems

Commercial ventilation systems often face multiple challenges, including:

- High pressure drop: Inefficiencies caused by internal component resistance reduce the overall energy savings.

- Limited space availability: Compact yet accessible AHUs are essential for easy installation and maintenance.

- Corrosive environments: High humidity levels or exposure to corrosive substances require durable and resistant components.

- Large airflow demands: In extensive buildings, AHUs must accommodate significant airflow capacities efficiently.

Challenges faced by Sovereign Air Movement

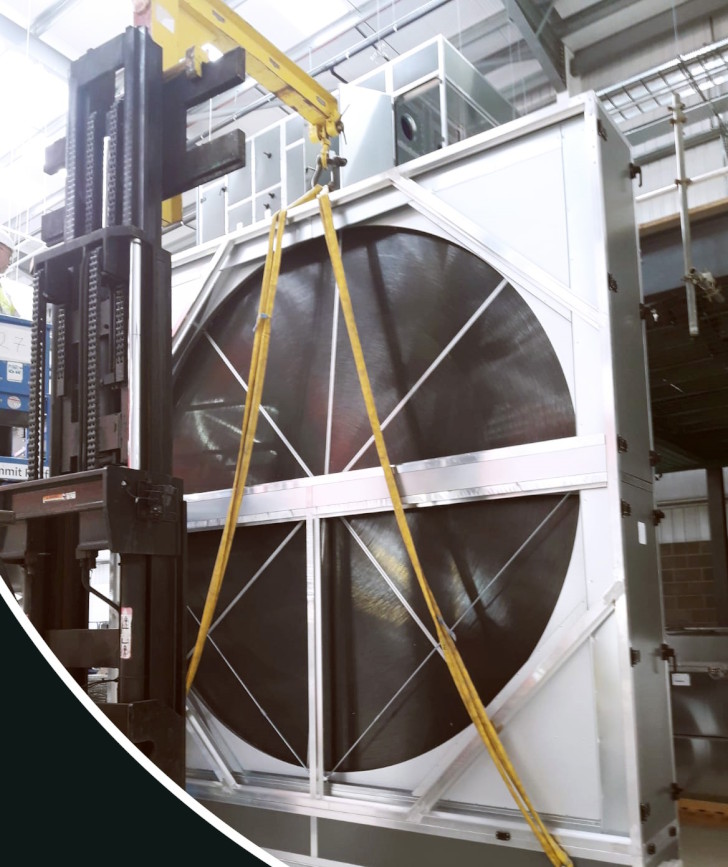

Sovereign Air Movement was tasked with designing a large AHU for an 80,000-square-foot facility. This required a sizable rotary heat exchanger capable of handling large airflow volumes while maintaining optimal efficiency.

Key challenges included:

- The AHU needed to be delivered in modular sections for on-site assembly.

- The total unit dimensions were 7095 mm (L) x 5250 mm (H) x 4150 mm (W).

- The required rotor specifications included:

- High-efficiency matrix

- Low pressure drop

- Large airflow capacity (~20 m³/s)

- Segmented wheel and casing for easy transport and installation

- Cost-optimized design without excessive oversizing

- Advanced drive and control equipment for improved operation

The solution: Heatex model EQ rotary heat exchanger

To address these challenges, Sovereign Air Movement selected the Heatex Model EQ rotary heat exchanger. Engineers from both companies collaborated to fine-tune the design, focusing on:

- Lowering pressure drop: To enhance system efficiency.

- Maximizing rotor size: The final size was optimized at 3800 mm in diameter.

- Choosing the perfect well height: A 1.8 mm well height was selected to accommodate the large airflow demands.

- Compact casing design: The rotor was enclosed in a compact casing that added only 140 mm to the overall size.

- Segmented rotor and casing: This feature ensured smooth on-site assembly and minimized logistical challenges.

Results and performance outcomes

The implementation of the Heatex rotary heat exchanger yielded impressive energy savings and efficiency gains. The following results were recorded based on continuous 24/7 operation in London, England:

- Installed power reduction: 535 kW of heating power saved compared to a system without an air-to-air heat exchanger.

- Annual energy savings: 1,283,023 kWh saved versus not using an air-to-air heat exchanger.

- Return on investment: The heat exchanger’s cost was covered within just one month of operation due to the significant energy savings.

Conclusion

Sovereign Air Movement’s successful integration of the Heatex Model EQ rotary heat exchanger demonstrates the impact of precision-engineered ventilation components in large-scale commercial applications. By optimizing heat recovery efficiency, reducing pressure drop, and ensuring easy on-site assembly, Sovereign Air Movement has delivered a highly efficient and cost-effective AHU solution. This case study underscores the importance of selecting the right heat exchanger technology to enhance system performance and sustainability in commercial ventilation projects.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.