In industrial plants, data centers, chemical refineries, and even historic hotels, heat exchangers are the silent heroes ensuring thermal balance, energy efficiency, and smooth operations. However, their vulnerability to fouling—caused by particles, organic matter, and biological growth—poses a persistent threat. The solution? Mechanical filtration.

By O. Oğuz Tameroğlu, CEO, Filternox

Why heat exchangers need protection

Whether it is a plate or shell-and-tube design, heat exchangers rely on clean, uninterrupted fluid flow to operate efficiently. But water drawn from cooling towers, rivers, lakes, or the sea often carries solid particles, sediment, algae, and corrosion byproducts. These contaminants reduce heat transfer, cause blockages, and increase pressure loss. Fouling—whether due to biofilm formation, mineral scaling, or particulate deposition—is not only a performance problem but also a cost and sustainability issue. According to studies, even a thin layer of fouling as small as 0.25 mm can reduce heat transfer efficiency by over 10%. As efficiency declines, energy consumption increases, which in turn raises operational costs and carbon emissions.

That’s where mechanical filtration becomes essential. By capturing unwanted solids before they enter the system, filters preserve the integrity and performance of heat exchangers.

Understanding the numbers

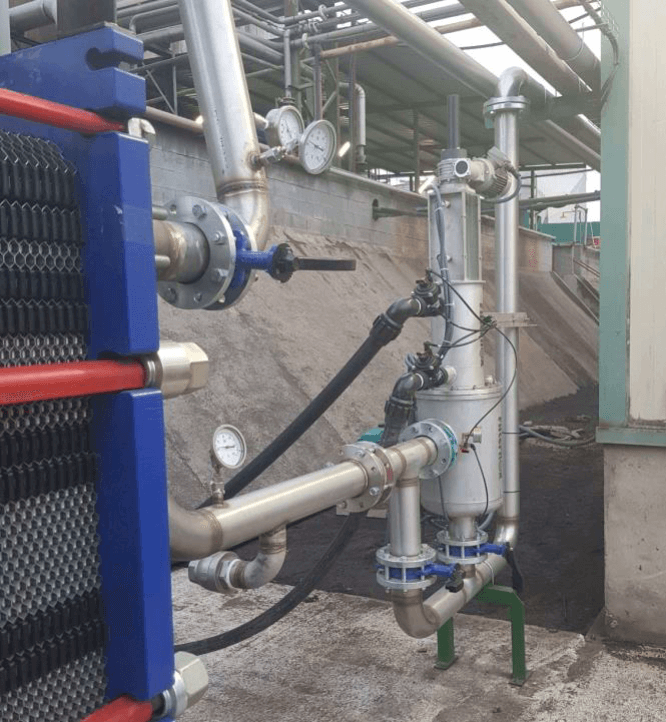

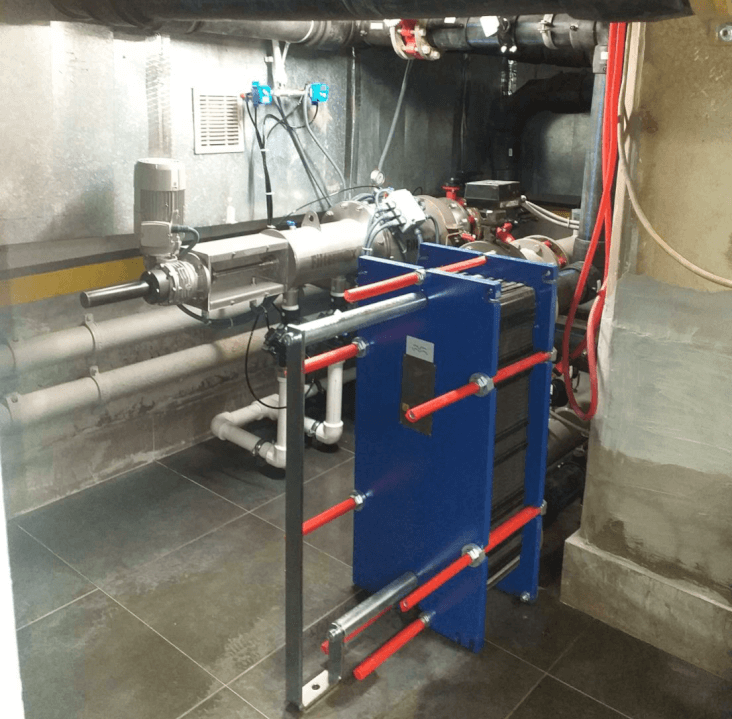

Choosing the correct filtration level is both a science and an art. For example, if a plate heat exchanger has a plate gap of 2 mm, the filtration rating should ideally be at least five times finer, approximately 400 microns. However, to provide a higher safety margin and account for particle variability, Filternox typically recommends a filtration degree of 200 microns in such cases.

In general, filtration degrees ranging from 50 to 500 microns are selected based on the risk of fouling, the water source, and the exchanger design. Even small particles can significantly affect performance in plate exchangers or form insulating layers inside tubular systems.

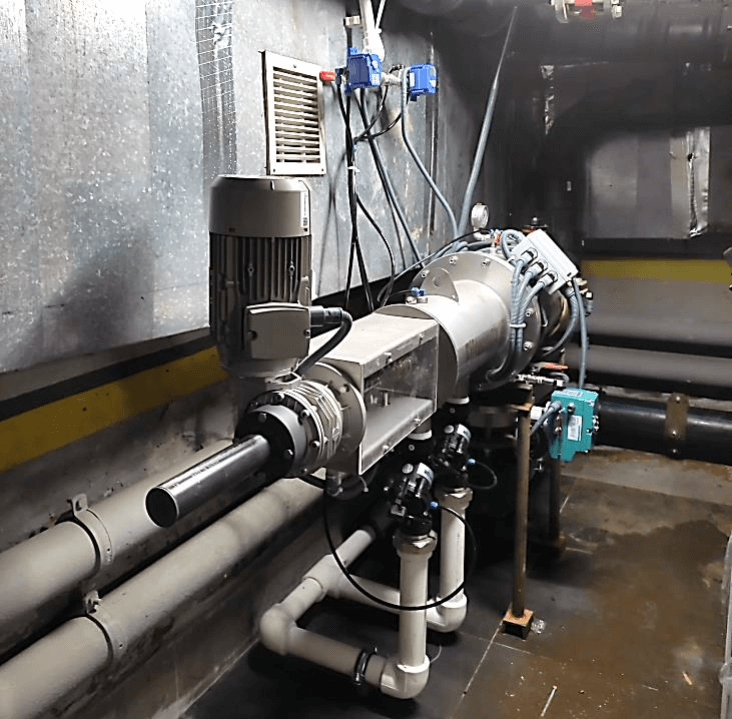

Also critical is the flow rate. For example, in systems handling flows above 100 m3/h, filters must be designed to handle the volume without creating pressure drops or requiring frequent manual maintenance. This is where automatic self-cleaning filters become indispensable.

Reliable cooling at the water’s edge: From iconic hotels to industrial strength

Overlooking the shimmering waters of the Bosphorus, the Çırağan Palace Kempinski in Istanbul is more than a symbol of luxury and history — it’s a testament to innovative engineering. Its seawater-cooled HVAC system, like many others near the coast, faces significant fouling risks, particularly in the summer months. Since 2004, Filternox® automatic self-cleaning filters have been the invisible guardians behind the scenes, ensuring uninterrupted performance even during peak tourist season.

But Çırağan is just one example. Prestigious properties such as the Four Seasons, Mandarin Oriental, Les Ottomans, Vakko Hotel & Residence, as well as leading institutions like Galatasaray and Bahçes¸ehir Universities, also rely on Filternox’s patented double-effect filters to protect their heat exchangers. These advanced filters capture not only fine particles but also large debris up to 5 centimeters in size, effectively eliminating the risks associated with seawater fouling.

And the result? Zero system failures in over 20 years of continuous operation — a record that speaks for itself. From five-star luxury to critical infrastructure, Filternox ensures that cooling systems run smoothly, efficiently, and without compromise.

This is achieved using patented double-cleaning technology that doesn’t interrupt the system or require manual intervention—the result: uninterrupted cooling, reduced maintenance, and a sustainable approach to energy efficiency.

But the benefits go beyond comfort. In industrial environments like petrochemical facilities and food processing plants, efficient filtration extends equipment life, reduces cleaning intervals, and ensures consistent product quality.

What makes a filtration system smart?

Innovative filtration isn’t just about particle size. It’s also about:

- Filter placement: Proximity to the heat exchanger matters. Filters should be installed inline, as close to the source as possible.

- Inlet pressure: Based on Filternox’s 30 years of experience, a minimum inlet pressure of 2 bar is recommended for efficient filter operation.

- Backwash interval and duration: Efficient automatic filters must be able to clean themselves without excessive water loss or interruption to the flow.

- Material selection: Filters operating in corrosive environments (like seawater) should be made of high-grade stainless steel, titanium, or duplex materials.

Cooling towers and surface water: A double challenge

Cooling towers bring their own set of problems. Airborne contaminants—such as leaves, insects, and microbes—accumulate in the water. Surface water sources, such as rivers and lakes, carry a wide variety of pollutants, including sediment, organic matter, and aquatic organisms. In coastal or offshore applications, shell fragments and algae blooms are common.

In these challenging environments, dual-stage automatic self-cleaning filters make the difference. They help reduce chemical usage, energy consumption, and the frequency of manual cleaning. Their long-term benefits include:

- Less frequent chemical dosing (antiscalants, biocides).

- Lower risk of emergency shutdowns.

- Reduced pump wear and tear.

- Stable thermal exchange capacity.

These savings translate not only into lower operational costs but also into environmental benefits. By maintaining clean heat transfer surfaces, companies can significantly reduce their carbon footprint.

Integration matters

Another often-overlooked factor is system integration. A filtration system must be appropriately integrated into the plant’s automation network. Features such as remote monitoring, differential pressure control, and alarm signaling allow for proactive maintenance and optimize filter cleaning cycles. Filternox filters, for example, can be directly connected to SCADA or PLC systems, enabling maintenance teams to respond before fouling causes system degradation.

Additionally, filters should be designed for easy inspection and minimal replacement of spare parts. Modular configurations make it easier to scale up or adapt to changing process requirements.

Why it matters more than ever

As the demand for energy-efficient, climate-resilient cooling systems grows, mechanical filtration plays a more strategic role than ever before. Industrial operators, facility managers, and engineers are realizing that a small investment in proper filtration upfront can prevent significant downstream losses, both financial and environmental.

In today’s world, where sustainability is no longer a trend but a necessity, filtration has become a core component of responsible industrial design.

By implementing reliable, automatic self-cleaning filters, operators can extend equipment lifespan, optimize heat exchange, minimize unplanned shutdowns, and support their ESG (Environmental, Social, and Governance) goals.

Conclusion

Filtration is no longer a secondary concern—it’s a frontline defense. In high-demand environments, protecting heat exchangers means protecting productivity and efficiency. With the right system in place, heat exchangers can perform as intended: run cleanly, efficiently, and continuously.

More about heat exchanger applications: https://www.filternox.com/pdf/en/Filternox-Sea-Water-Heat-Exchanger.pdf

About the Author

About the Author

O. Oğuz Tameroğlu graduated from the Department of Environmental Engineering at Istanbul Technical University in 1983. He worked at an RO facility Construction in Saudi Arabia between 1983 and 1986. He returned to Turkiye and founded Antel Treatment System Construction Industry & Commerce Co. in 1986. Since then, he has been leading the development and global promotion of advanced water filtration technologies, with a particular focus on automatic selfcleaning filters. As the CEO of Filternox®, he has overseen the design, production, and international deployment of filtration systems in over 80 countries.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About the Author

About the Author