Shell and tube heat exchangers are vital to industrial plant operations, and their efficiency can be improved through integrated solutions for both new and existing systems. Over the years, various methods have been developed to address corrosion and erosion, enhancing equipment longevity and material selection. Research has also focused on coatings that reduce fouling and improve energy efficiency, with studies conducted alongside industry partners. These patented solutions have been successfully applied in major oil & gas facilities over the past 30 years.

By Lorenzo Comel, Project manager, G.M.A. Srl

Years of research and applications in the field of anti-corrosive coatings for the prevention and elimination of corrosive and erosive phenomena of plant components including condensers and heat exchangers, have led to the development of patented technologies for the coating of tube bundles, including high thickness cladding of tube sheets, epoxy or composite lining of water boxes and internal lining of tubes using epoxy phenolic systems (tube ends or full-length lining).

Corrosion in heat exchangers

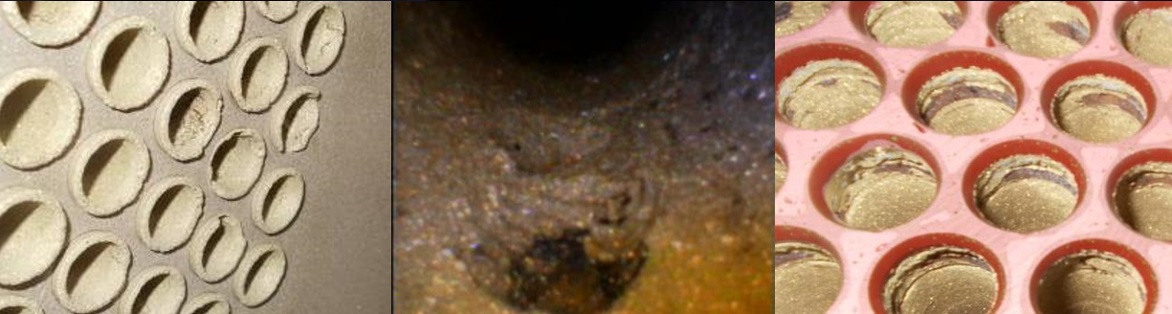

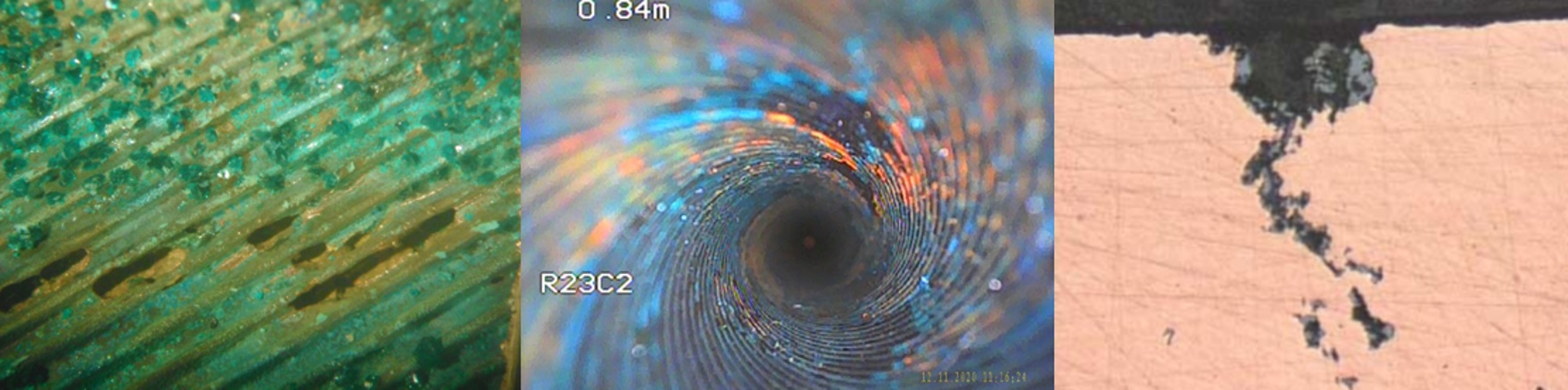

Heat exchangers are exposed to a dirty and aggressive environment and are susceptible to fouling and corrosion of tubes. Fouling increases resistance to heat exchange, decreasing the performance of the equipment and triggering corrosive processes under deposit. Fouling also requires expensive shutdowns to allow hydrodynamic or chemical cleaning of tube bundles. Tubes are made of different materials, ranging from carbon steel to copper alloys, to stainless steel, up to titanium. Problems related to poor design are many, including generalized corrosion, quick pitting, erosive phenomena…

In case of even just one small leakage, the process might be stopped to identify the issue and plug the damaged tube. For example, in the case of a hole of even a single tube of the steam condenser serving the turbine of a power plant using sea water, the presence of chlorides on the steam side requires timely actions that may lead to an unplanned shutdown of the plant. Also, if a microscopic hole occurs in a condenser tube serving a refrigeration unit, this causes the loss of large quantities of refrigerant gas and consequently the system will go out of service.

Figures 1-5 show some critical conditions identified over the years during onsite inspections.

Methods

Technologies for the coating of heat exchangers

Over the years, solutions capable of solving problems on the tube side have been developed, preventing damage caused by fouling, corrosion, erosion and cavitation, through the application of epoxy or phenolic resins on the surfaces of the tube plates, inside the tubes and water boxes of heat exchangers or condensers. Resins can be used both for cooling water circuits (even with steam cleaning) but also in the presence of aggressive media, with maximum operating temperature of 180°C.

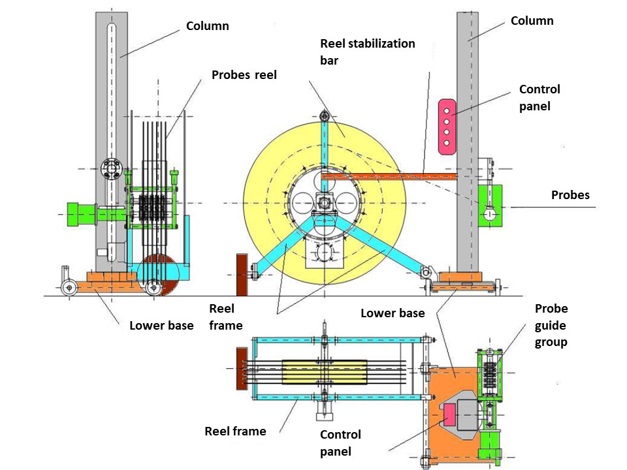

A patented semi-automatic system has been developed for full-length painting of tube bundles, that can be used for interventions both in the factory and on client sites.

The internal tubes painting machine is made up of four spraying probes which are inserted inside the tubes; the probes, using a radial nozzle, spray the paint product uniformly over the entire internal surface of the tube using air-mix technique with a thickness of approximately 50 microns per pass.

Studies of efficacy and durability

Durability tests have been carried out over time at accredited laboratories, including immersion tests in various solutions and salt spray for up to 2000 hours. In particular, long-term immersion tests in fresh water and brackish water according to ISO 2812 were carried out on the various formulations of resins, applied to samples of various base substrates. Further tests were carried out according to ISO 9227 to verify the resistance of the material to salt spray for up to 2000 hours. These tests are periodically repeated, to confirm the resistance of the materials following compositional variations (linked, for example, to regulatory requirements on a European basis) or in the case of formulation of new materials before their introduction into the painting procedures. Laboratory and field tests were also carried out to verify the influence of the application of the coating on the heat exchange ratio of tube bundle, with reference to the application on the full length of the tubes. Field applications are periodically monitored, allowing for the creation of a history of the durability of the coatings under various operating conditions.

Anti-fouling effect

Over the last few years, with the background of energy efficiency, the request from clients to identify solutions to reduce the adhesion of deposits on the internal walls of pipes has increased significantly, to limit or eliminate the need for costly cleaning interventions.

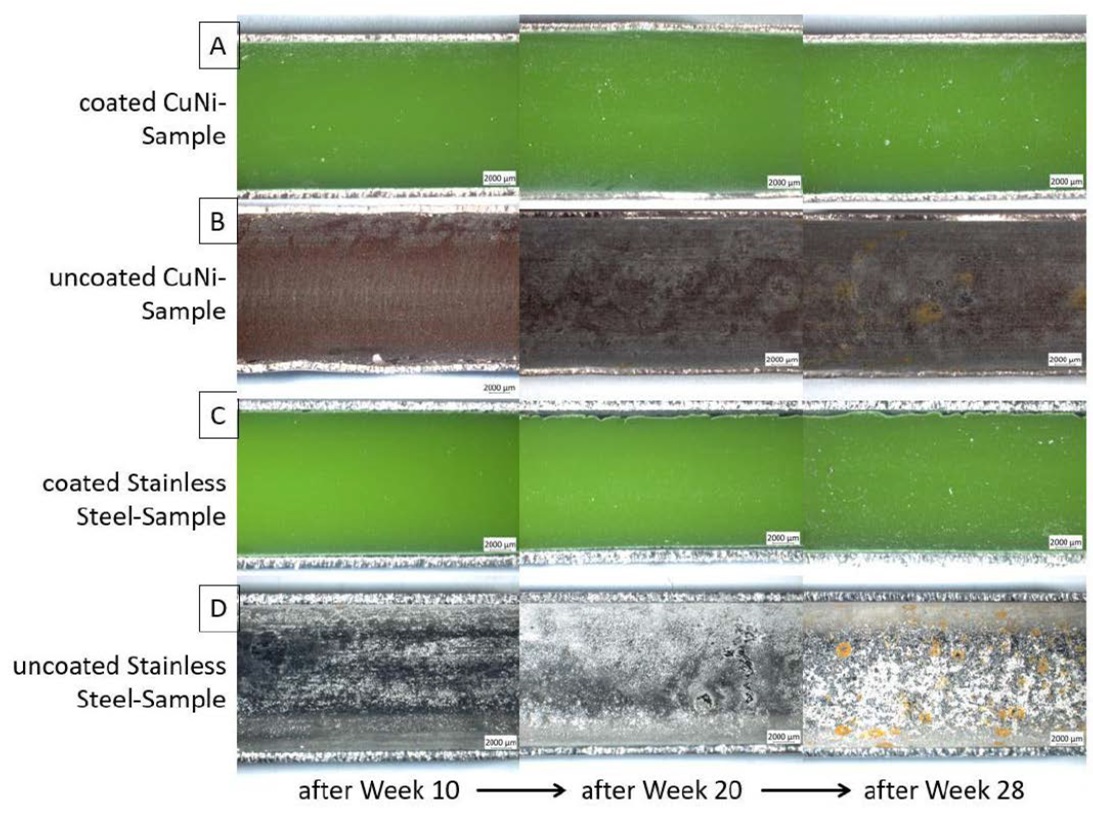

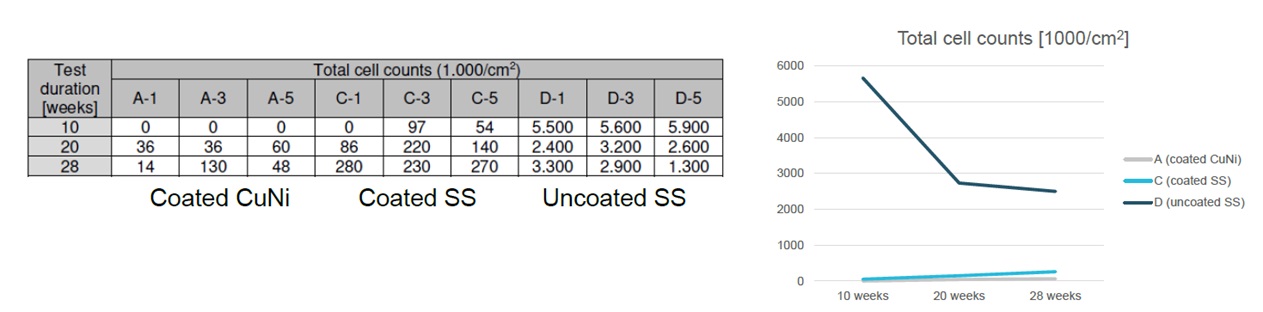

Fouling is a rather complex issue to study as there are no standardized test methodologies to measure the influence it has on the energy performance of a heat exchanger: it is therefore essential to determine the mechanisms of formation of biological deposits to scientifically evaluate the fouling resistance characteristics of coatings. Experimental studies on Cu-Ni and stainless-steel pipes inserted in a tube bundles model aimed at recreating the fouling conditions present in their industrial plants fed by river water have been carried out in collaboration with an important international partner. G.M.A. has recently completed under a POR FESR 2021-2027 Fund the CLEAN project – Coating Life Extension for Anticorrosive applications, which focuses on the following topics: in-depth analysis of the antifouling and heat exchange properties of the Phencote system for the coating of heat exchangers, optimization of the application system, LCA analysis of the process and creation of the related standards. The research phases have been performed with the collaboration of the Department of Engineering and Architecture of the University of Trieste and MaterialScan S.r.l.

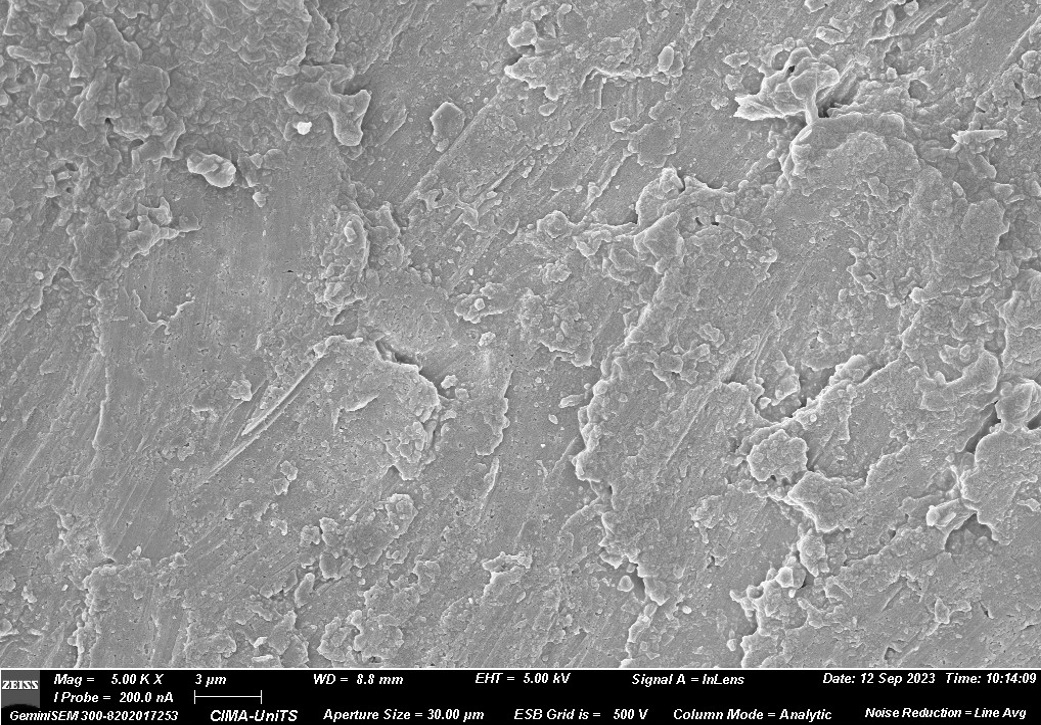

Based on this project, an experimental study has been completed, reproducing the effect of the coating on stainless steel, Cu-Ni and brass pipes with sea water circulation. In parallel, in-depth surface characterization studies of the materials, coated and not, have been carried out.

Results

Laboratory tests

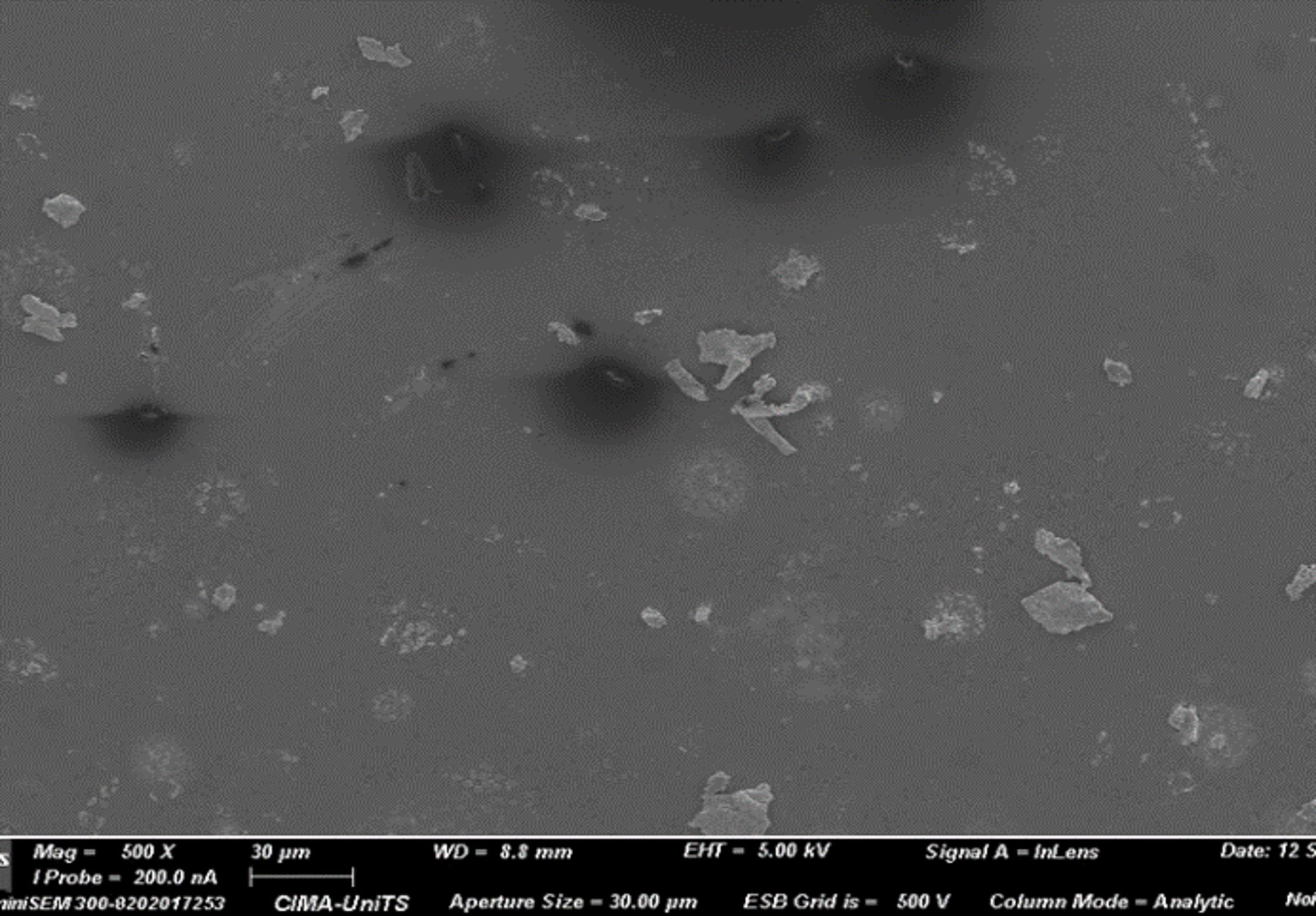

The morphological and instrumental analyses on the surface of the materials are aimed at verifying the possible role of the coating in terms of reducing the fouling effect. The results of the investigation show in general a significant reduction in roughness due to the presence of the coating compared to bare metal, in addition to a clear decrease in wettability, in particular compared to stainless steel and Al-brass. Visualization under the scanning electronic microscope allows to appreciate the greater uniformity of the surfaces in the presence of the coating. The conditioning tests in river and sea water in the long term (up to 28 weeks) show a significant beneficial effect of the coating in the adhesion of carbonate deposits. Regarding the formation of biological film, the cell count on stainless steel pipes shows values up to 60 times higher in uncoated pipes compared to coated ones.

Case study: Heat exchangers in a refinery

In 2013, 8 newly built tube bundles were coated, destined for installation at an Oil & Gas site in Libya. In previous years, the tube bundles, made of carbon steel and not coated, already showed significant problems in the short-medium term, both of a corrosive nature and of fouling, significantly affecting the efficiency of the plant. In synergy with the client, a coating cycle is implemented, which involves the application of an epoxy coating on the full length inside the tubes, completed by a high thickness coating (3 mm) on the tube sheets, designed to protect the tube/plate interface. Four years after commissioning, the exchangers are opened and subjected to a visual and endoscopic inspection. A comparative assessment is also made between the coated tube bundles and bundles of similar construction and same service, but without coating. The report, issued by the client, highlights the great difference in the presence of corrosion products and deposits in favor of the coated bundles, with the coating appearing perfectly preserved.

Conclusion

The use of epoxy and epoxy-phenolic coating systems on heat exchangers is a consolidated solution that allows to increase the performance and the life of the components, thanks to the anti-corrosion effect and the possibility of optimizing the metallurgical choices and avoiding any operational problems or design errors. Less known, but of primary interest in terms of energy efficiency and reduction of maintenance interventions, is the beneficial effect of the coating on the adhesion of deposits to the walls of the tubes, whether they are organic (biofouling) or inorganic (typically carbonates). Experimental studies have been carried out to measure this effect, confirmed by the experience in the field in the coating of tube bundles for the power and oil & gas sectors. Furthermore, a study, co-financed by the POR FESR 2021-2027 Fund has been completed, giving a deep analysis of the dynamics underlying the antifouling and energy efficiency effect related to the application of coating systems on tube bundles.

About the Author

About the Author

Lorenzo Comel holds a master’s degree in Materials Engineering. After a short experience in Biomedical field, he joined G.M.A in 2010, working in R&D department and getting qualifications as a coating inspector and NDT technician. Lorenzo currently works as a Project Manager, organizing anticorrosion coating activities in oil & gas, chemical and power plants.

References:

- R. Grassetti, S. Doria Protection of heat exchangers by means of coating their internal surface. CORROSION ITALIA 2003, Taormina, Italia

- R. Grassetti, S. Doria “Ottenere l’efficienza dello scambio termico degli scambiatori a fascio tubiero” (Achieving the heat exchange efficiency of shell and tube exchangers), Manutenzione, Tecnica e Management, 6/2000, 51-54

- L. Comel, R. Grassetti Conference Proceedings on “Protezione e ripristino anticorrosivo di scambiatori di calore e condensatori in centrali elettriche, raffinerie ed impianti petrolchimici” (Corrosion protection and restoration of heat exchangers and condensers in power plants, refineries and petrochemical plants) SAFAP. Milano, 16/11/2016

- L. Comel, A. Vanacore Conference Proceedings on “Corrosion in refinery and petrochemistry” EFC WP15 spring meeting. Lille, 30/03/2023

- L. Comel, Conference Proceedings on “revêtements (coating) utilisés pour protéger les échangeurs contre la corrosion” CEFRACOR Parigi 21.10.2021

- L. Comel, Conference Proceedings on “Coating systems to optimize durability and energy efficiency of heat exchangers”, AMPP Italy Conference & Expo, Genoa 10.06.2024

- L. Comel, Conference Proceedings on “Phencote coating system to optimize durability and energy efficiency of heat exchangers”, HEW Rotterdam 13.11.2024

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About the Author

About the Author