Milk bottling production line in a dairy plant. Photo: dreamstime.com

Multi-stage plate heat exchangers are transforming milk pasteurization by significantly improving energy efficiency, hygiene, and temperature control. Their compact design, high thermal performance, and ease of maintenance make them ideal for modern dairy processing. This article explores how they work and why they’re critical for safe, sustainable milk production.

Text by HFM

Heat exchangers are widely used in the food and beverage industry, especially in processes such as heating, cooling, pasteurization, and disinfection. They regulate temperature, ensuring that physical and chemical reactions occur at optimal conditions while guaranteeing that the final product is safe for human consumption.

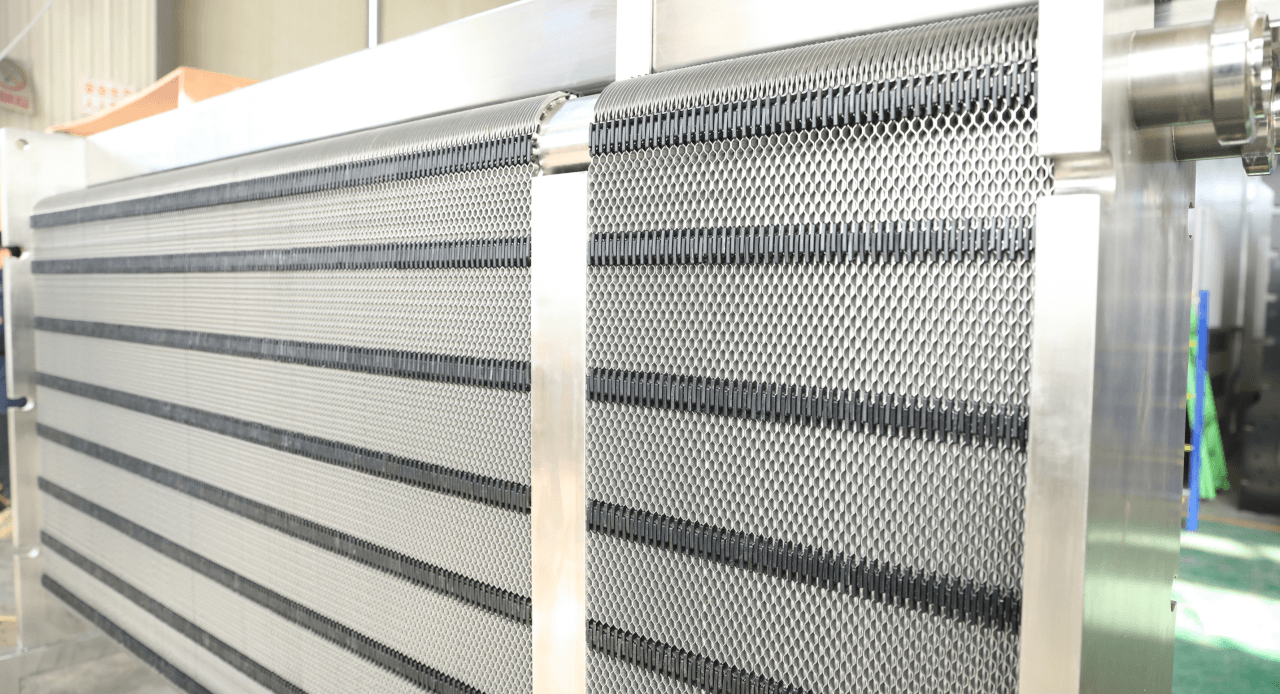

Plate heat exchangers are one of the most widely used heat exchangers for the dairy industry, because the design of this equipment provides large heat transfer area, which significantly enhances the turbulence while improving the heat transfer performance. Furthermore, since plate heat exchangers can be easily assembled and disassembled, maintenance and cleaning processes are very practical, which is essential in industries that demand high hygiene standards.

In the dairy industry, plate heat exchangers, specifically multi-stage one, are widely used in milk pasteurization, pre-cooling and cream separation, etc. It meets food-grade hygiene standards, such as EHEDG certification, which guarantees the safety and cleanliness of the processing. Because milk is a highly perishable product, pasteurization is essential to ensure the microbial safety of the product while not affecting its taste and nutritional value. This also requires attending to some of the strictest industrial standards and regulations. Effective pasteurization requires careful temperature management, and the use of plate heat exchangers can not only ensure the industrial standards but also increase the energy efficiency of during the production.

Basic principle of milk pasteurization

Pasteurization is a process developed by French scientist Louis Pasteur. It is conducted for the conservation of food and extension of their shelf life. It consists of the sterilization of food by killing harmful bacteria present in it through a subtle change in temperatures. If properly done, pasteurization ensures the microbial safety of the food, destroying pathogens, such as Tuberculosis bacillus and Escherichia coli. For dairy industry, specifically, as important as the safety of the milk for consumption, the process also must preserve its nutritional profile.

Early pasteurization methods often used direct steam injections or shell and tube heat exchangers. However, these traditional methods are characterized by low energy efficiency, unstable temperature control, large equipment footprints, and cleaning difficulties. In addition to that, these traditional methods often require a large amount of energy, which increases the cost for food producers. Currently, multi-stage plate heat exchangers are extensively used for milk pasteurization, they are usually composed entirely of stainless steel, allowing high standards of hygiene.

Multi-stage plate heat exchanger

Multi-stage plate heat exchanger is also a type of gasket plate heat exchanger. It can be used for heating and cooling two or more fluids, usually separated by intermediate frame, and can be manufactured into 2-stage, 3-stage, 4-stage, etc. The intermediate frame has connections for the circulation of media. Usually, the material of the intermediate frame is SS304 or SS316, since all the parts in contact with the medium should be made of stainless steel in order to avoid oxidation, cross-contamination and other pathologies of the heat exchanger. As for the gaskets, they can be made of NBRF, NBR-HTF, EPDMF, etc.

Multi-stage plate heat exchangers include a multitude of advantages, such as:

- High heat exchange efficiency and low operating costs.

- Compact design, small footprint, easy to install.

- Easy maintenance, convenient disassembly for mechanical cleaning.

- Easy expansion to add plates, increasing heat exchanging area.

- Good turbulence effect, not prone to scaling.

Milk pasteurization process in multi-stage plate heat exchanger

Step 1: Preheating (regeneration zone)

Cold milk is first passed through the heat exchanger to receive thermal energy from the hot milk that has already been pasteurized, preheating it to a temperature close to the pasteurization temperature. As hot milk in the pasteurization cycle flows through the heat exchanger, it transfers heat to the incoming cold milk. This process reduces the amount of energy required to heat the milk to pasteurization temperature and is a key demonstration of the plate heat exchangers system’s heat recovery capability.

Technical details: The temperature difference between the hot fluid and the cold milk and the control of the flow rate are central to the optimization of thermal efficiency.

Step 2: Pasteurization (heating zone)

This is the critical stage for destroying harmful bacteria. At this point the milk is further heated to the required pasteurization temperature, usually 72°C for 15 seconds according to the High Temperature Short Time (HTST) method, to enter the sterilization phase. The heating medium, usually hot water or steam, transfers heat through the other side of the heat exchanger plate for precise and uniform temperature control.

Technical details: Ensure constant flow rate and uniform temperature distribution to prevent overheating or under-sterilization.

Step 3: Insulation (insulated pipes)

After reaching the target temperature, the milk needs to be maintained in the holding tube for a certain period (e.g. HTST at 72°C for 15 seconds) to ensure that there is enough heat to complete the sterilization process. Plate heat exchangers systems can also be used with heat recovery at this stage to improve energy efficiency.

Technical details: Key variables include flow rate and duration within the holding zone to meet food safety requirements and ensuring that the pathogens will be killed.

Step 4: Cooling (cooling zone)

After sterilization, the milk must be rapidly cooled to below 4°C to inhibit microbial regeneration to ensure freshness and extend shelf life. At this point, the heat exchanger quickly reduces the temperature of the milk by means of a cooling medium (e.g. chilled water or other cooling medium).

Technical details: Factors such as the temperature difference between the milk and the cooling liquid and the efficiency of heat transfer as well as the heat transfer capacity of the PHE directly influence the cooling rate.

Energy efficiency and sustainability advantages of multi-stage plate heat exchangers

The multi-stage plate heat exchanger system significantly reduces the consumption of steam and hot water in the milk pasteurization process by efficiently recovering heat energy through the regeneration section, thus minimizing energy costs and improving overall economic efficiency. At the same time, the system optimizes the energy performance of the heating and cooling stages, which not only improves production performance but also helps to reduce carbon emissions. This is important for the dairy industry to achieve the goals of energy saving, emission reduction and sustainable development.

Hygiene, maintenance and food safety essentials include:

- Cleanliness and hygiene guarantee

Cleanliness and hygiene of the plate heat exchanger are crucial in dairy processing. Regular cleaning and sanitizing can effectively prevent microbial contamination and ensure product safety. PHE is easy to disassemble and clean for maintenance, preventing microbial residues, and its structural design helps to comply with strict food hygiene regulations. - Cross-contamination prevention

Multi-stage plate heat exchanger system is designed to minimize the risk of cross-contamination between milk and other processing media, further enhancing the safety and reliability of food production.

Conclusion

The application of multi-stage plate heat exchangers in milk pasteurization not only improves thermal efficiency and operational flexibility, but also reduces energy consumption and operating costs, while ensuring food safety and hygiene standards of the product. As the concept of sustainable production continues to deepen, heat exchangers technology is continuing to evolve towards greater efficiency, automation and environmental protection, injecting new momentum into the green transformation of the dairy industry.

As an advanced energy-saving equipment, multi-stage plate heat exchangers not only help companies to meet the industry’s regulatory requirements, but also respond to consumer demand for high-quality, sustainable dairy products, which is an important step towards the future of the food industry.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.