Welder at work on a skived aluminium profile during assembly. Image courtesy of SAG.

The world is rapidly shifting due to climate, political, and economic crises, impacting all industries. New data highlights the need for more efficient operations in process industries. For example, the U.S. Department of Energy reports that 20–50% of industrial energy is lost as waste heat — yet heat recovery solutions are often overlooked. One such solution is the skived fin (SKF) aluminium heat exchanger, which offers outstanding performance but remains little known. Let’s explore its technical features and uses.

Maxime Blondin, Marketing & Communication Officer, SAG Industries

Unique technology with unique attributes

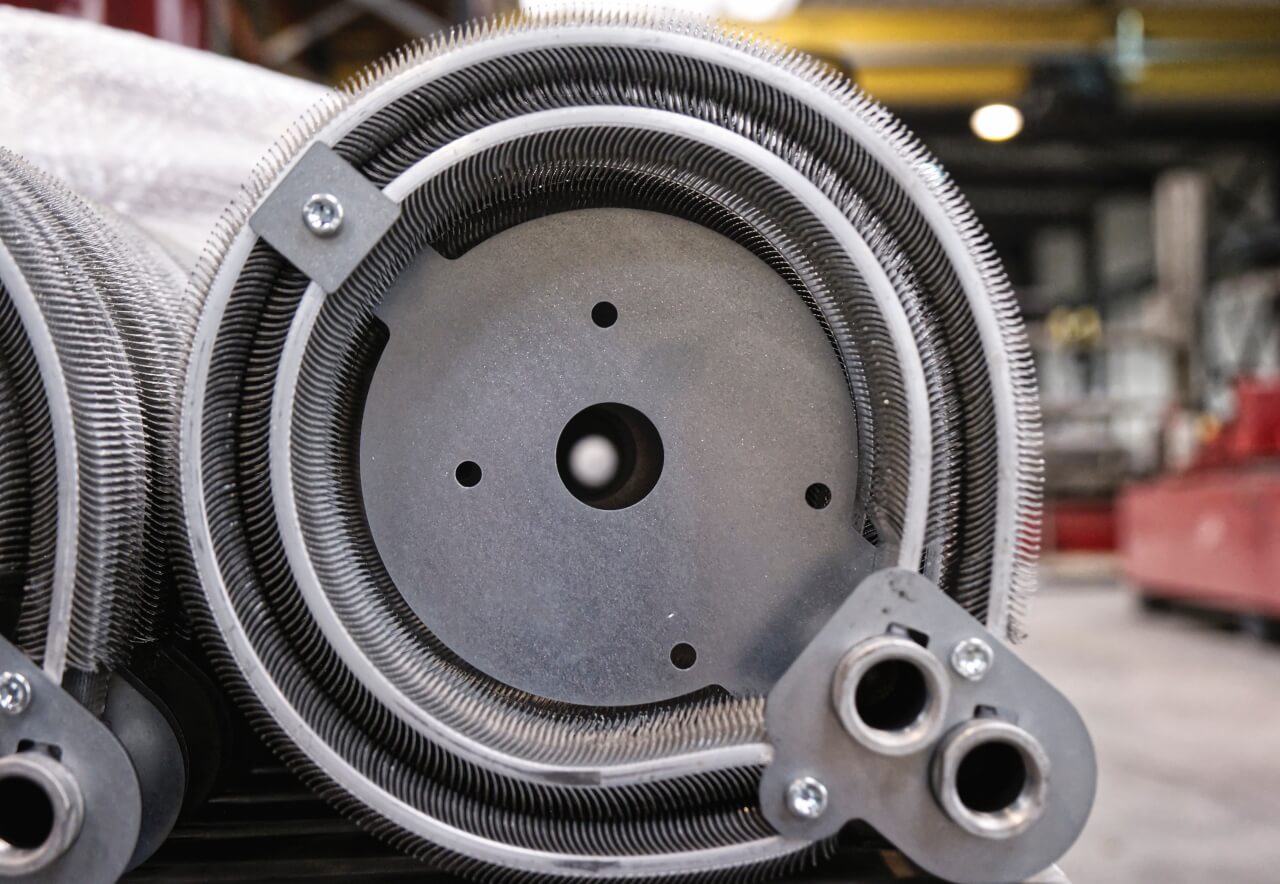

Designed and made by only a few companies in the world, skived fin heat exchangers provide top notch performance thanks to the material used as well as their fabrication process.

SKF exchangers are made by skiving fins directly into an aluminium frame profile, preventing most material loss as opposed to machining and avoiding any soldering which could decrease the heat transfer coefficient and create fragility areas. This fabrication method offers the following benefits:

- Excellent pressure resistance, above 60 bars, thanks to a multi-channel geometric profile

- Excellent vibration and shock resistance

- Very high exterior surface/interior profiled air section compared with classic finned tubes

The aluminium used also plays a big part in their high efficiency, offering high thermal conductivity as well as the following advantages:

- Lightness

- Flexibility (easy to shape by folding or bending)

- Increased corrosion resistance with various coatings

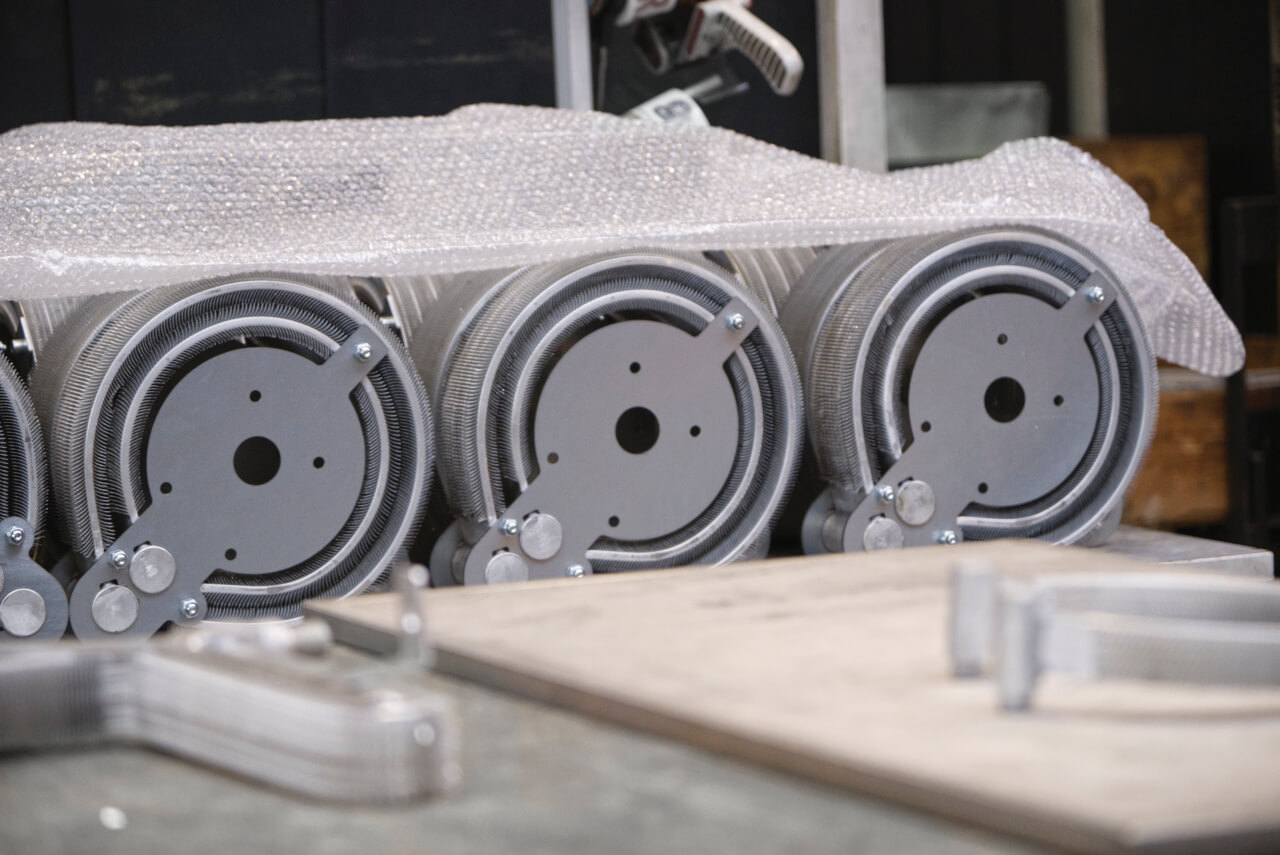

Altogether, these strengths also offer a light, compact and durable product, thanks to its malleability and heat transfer coefficient, which makes it easy to integrate into many machines.

Versatility meets efficiency

Despite remaining relatively unknown, the skived fin technology is already playing a critical role in multiple industries where heat must be managed under pressure, vibration, and tight space constraints.

In air compressors, particularly oil-free or high-performance units, these exchangers are used to efficiently dissipate heat from the compression process. The skived fin structure allows for a high surface area within a compact volume.

In industrial refrigeration, HVAC, and heat pump systems, where rapid, efficient, and reliable heat extraction is essential, skived fin exchangers enhance the system’s COP (Coefficient of Performance), directly reducing energy consumption and ensuring stable temperatures under varying loads.

In heavy-duty applications, such as in off-road trucks, the railway industry, construction equipment, and specialized vehicles from manufacturers like MAN, these devices are often integrated into charge air cooling (CAC), oil cooling systems or intercoolers to handle extreme thermal loads, ensuring optimal engine performance and extended service life. The high vibration resistance of these exchangers is also a key advantage for that sector.

Taking advantage of aluminium’s shaping capabilities and high-precision manufacturing, customized skived fin exchangers meet the exact requirements of various thermal management needs. Whether in stationary industrial units or mobile heavy machinery, they provide a reliable and durable solution for maximizing heat transfer and minimizing operational risk.

Tailored to your needs

You may have noticed the repeated emphasis on “custom” skived fin exchangers throughout this article, and for good reason. While OEM solutions are available, they often come with limitations. In contrast, custom-designed exchangers are tailored to your specific process requirements, unlocking the full performance potential of this unique technology.

Whether used in industrial machinery, military vehicles, or commercial and medical refrigeration, custom skived fin exchangers consistently deliver superior results. Now that you’re familiar with their advantages, you may agree that it’s time to consider a bespoke solution for your application.

About the author

About the author

With a degree in marketing and a background in science, Maxime joined SAG to highlight the company’s expertise in customized heat exchangers through modern, technical B2B marketing and communication.

About SAG Industries:

SAG Industries is a Belgian designer and manufacturer of custom heat exchangers and related process equipment. The family-owned group is structured around four business units: industry, pharma, air coolers, and special equipment. SAG serves a wide range of sectors including pharmaceuticals, nuclear, oil & gas, chemicals, renewable energy, defense, and more.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.

About the author

About the author