For nearly half a century, Alabama Heat Exchangers has been a trusted name in the fabrication, repair, and servicing of heat exchangers across multiple industries. Today, under the leadership of President and CEO Ricky Lightcap Jr., it is preparing for a new chapter, one marked by a generational ownership transition, deeper involvement in industry organizations, and investments in advanced technologies. By blending tradition with innovation, Alabama Heat Exchangers is positioning itself to meet evolving market demands while preserving the personal touch that has long defined its success.

In this exclusive Heat Exchanger World interview, we explore the company’s journey, culture, and vision for the future.

Building on strong foundations

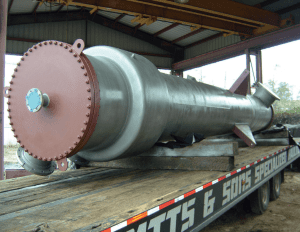

Founded in 1986 by Rick Lightcap, Sr. and his wife Cathy, Alabama Heat Exchangers grew steadily by serving local refineries, chemical plants, and industrial facilities with reliable heat exchanger fabrication and maintenance. The founders built the company around a simple promise: deliver quality work, stand by your customers, and treat employees like family.

“Those values haven’t changed,” Lightcap explained. “We may be looking at automation and new markets today, but at our core, we’re still the same company built on relationships and integrity.”

Over the years, Alabama Heat Exchangers developed expertise in custom fabrication, field services, and emergency repairs, earning long-term loyalty from customers who often faced urgent turnaround schedules. “We’re the company you call when the exchanger has to be back online in days, not weeks,” Lightcap said. “That responsiveness has been one of our biggest differentiators.”

Today, the company serves industries ranging from oil and gas to power generation, petrochemicals, and emerging clean energy sectors. Its workforce combines decades of hands-on experience with new engineering talent, bridging generational skills in the shop and field.

A generational transition

The most significant change in the company’s history was signified by ownership transition from the founders to Ricky Lightcap Jr., marking a generational handover.

“This is a huge moment for us,” Lightcap said. “The founders created an incredible foundation, and now it’s my turn to carry it forward. It’s not just about ownership, it’s about responsibility, continuity, and vision.”

Lightcap’s connection to the company is both professional and personal. Having worked his way up through leadership roles, he understands the culture, customer base, and technical demands. “I grew up around this industry. I’ve seen firsthand what makes Alabama Heat Exchangers successful, and I know what’s at stake. Taking on ownership is about honoring that history while steering us toward the future.”

The transition has been carefully planned to avoid disruption for employees and customers.

“Continuity is key,” Lightcap emphasized. “The people who built this company are still here. The same teams are on the floor, the same engineers are drawing up plans, the same field crews are responding to calls. What changes is how we adapt to new market demands, not who we are at our core.”

This shift reflects a broader industry reality: many long-established companies are undergoing leadership transitions as founders retire. Alabama Heat Exchangers’ approach is to preserve its DNA while reenergizing the business with new ideas.

A seat at the table: Leadership in TEMA

Another defining step for Alabama Heat Exchangers has been its growing role in the Tubular Exchanger Manufacturers Association (TEMA). Lightcap joined TEMA about 2 years ago and formally became the Vice President of its Executive Committee during the 2025 TEMA summer meeting in Quebec City.

“Joining TEMA and taking on this role is about more than recognition,” Lightcap explained. “It positions us to have a voice in shaping the standards that guide our entire industry. As a member, you’re not just following, you’re aslo influencing where we go as a field, and TEMA has always been recognized as the gold standard for shell and tube heat exchanger design and fabrication.”

For customers, this translates into confidence.

“Clients see that we’re directly involved with TEMA and it reassures them,” Lightcap said. “It tells them we’re committed to the highest standards of quality and equipment safety, and that we’re helping to push the industry forward.”

TEMA’s influence spans everything from technical design standards to fabrication best practices. Being part of that dialogue gives Alabama Heat Exchangers early insight into evolving regulations, material advancements, and global challenges like carbon capture. “We’re able to bring that knowledge back to our team and our clients, so they’re more than prepared to react to change,” Lightcap noted.

Embracing technology and automation

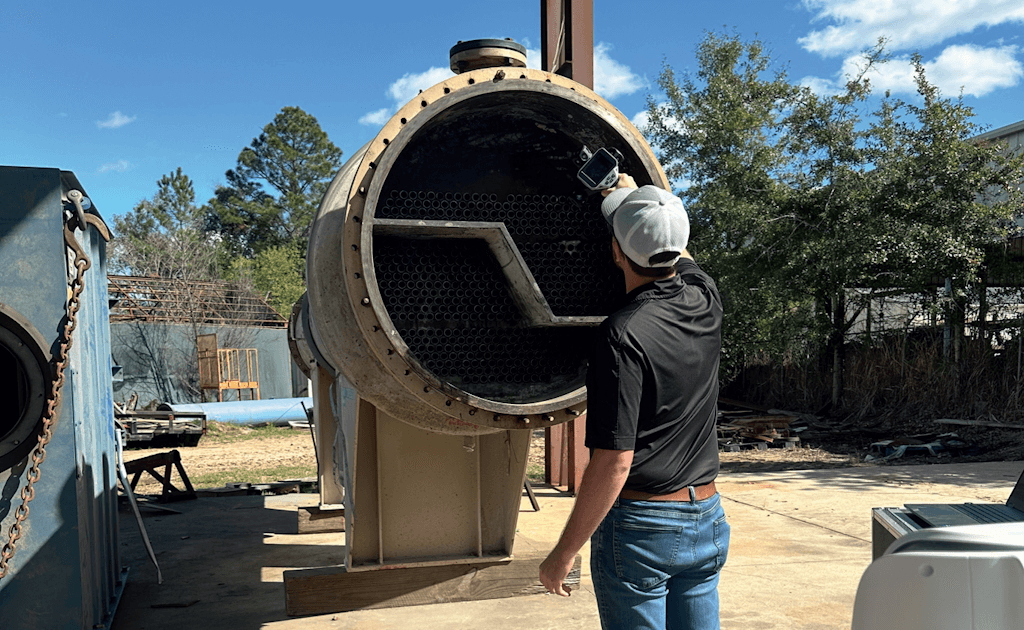

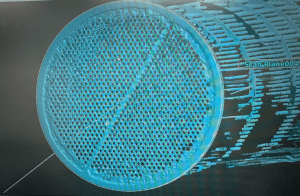

While Alabama Heat Exchangers has always been defined by skilled craftsmanship, the company is now exploring advanced tools that can transform how it works. Two key initiatives stand out: drawing automation and 3D scanning.

“These tools are game-changers,” Lightcap said. “With 3D scanning, we can capture precise measurements of an exchanger in a fraction of the time. That reduces errors, shortens timelines, and gives clients a level of detail they’ve never seen before.”

Drawing automation, meanwhile, offers the chance to streamline design processes. “Instead of spending hours or days manually creating drawings, automation can generate them almost instantly,” Lightcap explained. “That doesn’t replace our engineers, rather than it empowers them. They can focus on problem-solving and optimization rather than repetitive tasks.”

The combination of traditional know-how and digital precision has far-reaching implications. Faster turnarounds mean less downtime for clients. Greater accuracy means fewer reworks. And 3D modeling capabilities allow Alabama Heat Exchangers to walk customers through designs visually, improving collaboration and trust.

“We’re in the early stages of testing these technologies,” Lightcap admitted, “but if the results continue to match what we’ve seen so far, we’ll be moving forward quickly.”

Automation is not about replacing people, he emphasized, but about enhancing what they can do. “Our team is the heart of this company. Technology is just another tool in their hands to deliver better results.”

Navigating market shifts

Like many companies in the heat exchanger space, Alabama Heat Exchangers has faced fluctuations in demand. Earlier this year, the market softened a bit, but Lightcap noted it’s now rebounding as expected. “We’re seeing business starting to really take off, which gives us confidence going into next year,” he said.

One of the most exciting areas of opportunity is carbon capture and CO2 emissions reduction. “We’re seeing increasing demand for exchangers tied to carbon capture systems,” Lightcap explained. “As companies invest in reducing emissions, we’re in a position to support them with the equipment they need.”

This reflects broader changes in the energy landscape. Traditional oil and gas markets remain strong, but clean energy and emissions reduction projects are growing fast. Heat exchangers are central to both. “They’re the hidden workhorses,” Lightcap said. “A more efficient exchanger goes beyond saving money, it reduces emissions, improves safety, and extends the life of critical equipment.” Alabama Heat Exchangers is also diversifying its customer base to ensure stability. “We serve multiple industries—chemical, petrochemical, power, and more,” Lightcap said. “That balance helps us weather cycles in any one sector.”

A culture of care: Customers and employees

Beyond technology and markets, Lightcap is clear about what really sets Alabama Heat Exchangers apart: its people and its culture.

“One of the things I’ve always admired here is how personal it feels,” he said. “Customers know us by name, and we know them. That trust goes beyond transactions, it’s relationships built over decades.” The same applies internally. Employees are treated like family, with many spending decades at the company. “Our people are our biggest strength,” Lightcap emphasized. “They bring not only skill but loyalty, and that translates directly to the quality our customers experience.”

This culture also means adaptability. Whether it’s a small repair or a major fabrication project, the team approaches each job with flexibility and responsiveness. “Every exchanger is unique,” Lightcap said. “We don’t force a one-size-fits-all solution. We listen, we adapt, and we deliver.”

Customers have noticed. Many have relied on Alabama Heat Exchangers for decades, calling on them for urgent turnarounds and complex projects alike. “It always comes back to trust,” Lightcap reflected. “That’s what keeps people coming back, even as markets and technologies change.”

Looking ahead

As the company prepares for its generational transition, Alabama Heat Exchangers is focused on balancing tradition with innovation. Lightcap envisions a future shaped by three priorities: strengthening people, investing in technology, and supporting sustainability.

On the workforce side, training and development will ensure the next generation of employees is equipped with both practical skills and digital fluency. “We’re not just building exchangers,” Ricky said. “We’re building careers. Investing in our people is how we secure our long-term future.”

On the technology side, the adoption of automation and 3D tools will be expanded, with an eye toward reducing lead times and enhancing precision. “We want to be the company clients think of when they need cutting-edge solutions that still come with personal service,” Lightcap said.

On the sustainability side, Alabama Heat Exchangers is positioning itself to support carbon capture, emissions reduction, and efficiency improvements. “If we can help our clients operate more sustainably, then we’re contributing to something bigger than ourselves,” Lightcap noted.

Ultimately, Lightcap sees his role as stewarding a legacy while writing a new chapter. “This company has been around for decades because it stayed true to its values while adapting to change,” he said.

“My job is to continue that tradition. The heat exchanger industry may evolve, but the need for quality, reliability, and trust will never go away.”

Conclusion

The story of Alabama Heat Exchangers is one of continuity and transformation. With an impending generational leadership transition, growing influence in TEMA, new investments in automation, and a deeply rooted customer-first culture, the company stands at a pivotal moment.

As Ricky Lightcap Jr. put it: “This isn’t just about carrying on a legacy—it’s about building the future.”

With that mindset, Alabama Heat Exchangers is more than ready for the decades ahead.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.