This article will explore three examples of how low-fin and dual enhanced tubes are used for condensing services to improve heat transfer efficiency and reduce capital expenditure.

By Himanshu Joshi, Heat Exchanger Specialist, Lou Curcio, Heat Transfer Advisor, and Thomas Lang, Manager Product Management – Process Industry, Wieland Thermal Solutions.

The design of most compact and efficient heat exchangers for new plants or maximal performing heat exchangers in a revamp/upgrade situation in an existing plant demands innovative solutions. In this article we focus on the shellside condensing services with cooling water on the tubeside. The cases presented demonstrate the performance improvement capabilities with low-fin and dual enhanced tubes. Depending on the situation for an existing or new plant design the focus varies between the optimization of OPEX and CAPEX. Refer to Parts 2-4 of this series of articles for background on controlling resistance, finned tubes, and dual enhanced tubes.

Case 1: Petrochemical Plant C3 Refrigerant Condenser

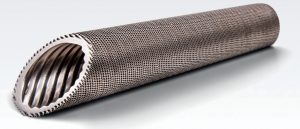

This case is a water-cooled C3 refrigerant condenser and a simple tube bundle upgrade from plain to low-fin Wieland GEWA-K tubes (Fig. 1). During summer months with high cooling water inlet temperatures of 27 °C, the C3 condenser capacity limits the compressor performance. Given the constraint of the cooling water flow rate, the only choice to boost the capacity from 6.3 to 9.4 MW (+49 %) is to add surface on the shellside for the condensing C3 refrigerant stream. As shown in Table 1, a low-fin tube with 19 fpi was selected. Selecting the optimal fin density for shellside condensation is essential for performance improvement. The key parameter for good liquid condensate drainage is the surface tension. The condensation model developed by Rudy and Webb in 1985 [1] offers a very good starting point for calculating fin density (Fig. 2). However, for a comprehensive design, additional parameters such as fin efficiency, which depend on the thermal conductivity of the tube material, and bundle effects, impacted by bundle size and tube layout, must be considered.

Table 1. C3 refrigerant condenser in petrochemical plant – Heat duty and feed rate improvement using low-fin tubes (Case 1)

| TEMA type AEM | Existing plain tube | Wieland GEWA-K tube upgrade |

| Heat duty, MW (% increase) | 6.3 | 9.4 (+49%) |

| C3 flowrate, kg/s (% increase) | 13.5 | 20.2 (+49%) |

| Mean Temp Difference, K | 11.0 | 8.0 |

| Tube type | 19.05 mm OD x 2.77mm AW* | 19fpi, 19.05mm OD x 2.34 mm AWUF* |

| Shell ID x tube length x tube count | 1200 mm x 6.1 m x 1820 tubes | |

| Effective area, m2 | 651 | 1668 |

* AW – average wall, AWUF – average wall thickness under fins

Case 2: Seawater-cooled C3 condenser

An opportunity arose to upgrade a boil-off condenser at a tank farm in southern France, coinciding with efforts to extend the service life of this seawater-cooled condenser. The original tubes were 19.05 mm OD, 90/10 CuNi tubes with 19 fpi which had been the reference in the early days of chiller packages. With the lifetime extension, the objective of the operator was to (1) maintain the duty of 2.7 MW at maximal summer cooling water temperature and, (2) to have maximal duty with maximal water flow rate if needed. The analysis of different enhanced condensing structures (Table 2) showed that using the dual enhanced Wieland GEWA-CLF tube (Fig. 3) for Objective 1, the heat duty can be maintained at a higher sea water inlet temperature (28.0 degrees C vs 24.8 degrees C), and for Objective 2, a heat duty improvement of 50% can be obtained.

The heat exchanger design is with a BEM TEMA type, two tubepasses, shell ID 830 mm and 672, 19.05 mm OD tubes with a tube length of 4.275 m. This particular service is prone to tubeside fouling and in a future article we will address how that might affect the selection of enhanced surfaces.

Table 2. Boil-off condenser – Summary of improvements using dual enhanced Wieland GEWA-CLF tubes (Case 2)

| Performance goal | Max. seawater temperature | Max. seawater flowrate | ||

| Tube type | Low-fin 19 fpi | GEWA-CLF | Low-fin 19 fpi | GEWA-CLF |

| Duty, MW (% increase) | 2.7 | 2.7 | 3.2 | 4.7 (+50%) |

| Seawater flowrate, kg/s | 153.0 | 193.7 | ||

| Seawater temp. in/out, °C | 24.8/29.0 | 28.0/32.2 | 23.5/27.5 | 23.5/29.3 |

| Mean Temp Difference, K | 10.1 | 6.6 | 11.6 | 10.4 |

Case 3: LNG plant – water cooled C3 refrigerant condenser

Dual enhanced GEWA-KS tubes (Fig. 4) have been applied in a major LNG plant design. In comparison to conventional low-fin tubes, a substantial size and weight reduction (-30 %) offers significant savings in CAPEX and plot space (-40 %) as shown in Table 3.

The reference case presented is with a condensing capacity of 292 MW distributed on four shells, TEMA NXN type heat exchanger. After the desuperheater, the propane refrigerant is entering at saturated conditions with Tsat = 46 °C on the shellside. On the tubeside closed cycle cooling water is flowing in a 1-pass arrangement with 31 °C at the inlet and 41°C at the outlet.

Table 3. LNG C3 ref. condenser – Summary of improvements using dual enhanced Wieland GEWA-KS tubes (Case 3)

| 19.05 mm GEWA-K Tube (OD: 30fpi, ID: plain) | 19.05 mm GEWA-KS tube (OD: 30 fpi, ID: low fouling helical fins) | |

| Shell ID, mm | 2280 | |

| Tube count | 6448 | |

| Tube length, m | 12.2 | 7.32 (-40% reduction) |

| Equipment dry weight, tons/shell | 115 | 82 (-30% reduction) |

Summary

This article has highlighted three examples of common heat exchange services that can benefit from the application of low-fin and dual enhanced tubes in place of conventional plain and low-fin tubes.

- In the case of a tube-by-tube replacement of a petrochemical plant C3 refrigerant condenser, low-fin tubes replacing the existing plain tubes enabled a 49% increase in heat exchanger duty at summer conditions with maximal cooling water inlet temperatures.

- In the case of life-time extension of a seawater-cooled propylene boil-off condenser, dual-enhanced Wieland GEWA-CLF tubes in CuNi 90/10 resulted in a 50% increase in duty with operational improvements for high summer cooling water inlet temperature or maximal cooling water flow rate and duty.

- For a propane refrigerant condenser in a mega-size LNG plant Wieland GEWA-KS tube allowed for the maximal flexibility in both CAPEX and plot space reductions.

Upcoming in this series

In the next few articles we will look at other case studies and how fouling might affect finned tube selection.

Reference:

[1] Rudy, T.M. and Webb, R.L., “Condensate Retention of Horizontal Integral-Fin Tubes” ASME Journal of Heat Transfer, Vol. 107, No. 2, May 1985.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in December 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

![Figure 2. Preferred fin densities for selected condensing fluids [1] Figure 2. Preferred fin densities for selected condensing fluids [1]](https://heat-exchanger-world.com/wp-content/uploads/sites/19/2026/01/hte6-3.jpg)