As concerns around food and environmental safety continue to reshape the animal feed industry, producers are under increasing pressure to eliminate chemical treatments while maintaining product quality and energy efficiency. In response, Dutch-based co-operative Royal Agrifirm, in partnership with Solex Thermal Science, has pioneered an innovative, chemical-free process for treating animal feed using radio frequency waves and advanced heat recovery systems.

By Jean-Marc Reichling, Stan Pala and Sven van der Heide, Solex Thermal Science

Background

Animal feed processing has come under intense scrutiny in recent years as consumer advocacy groups, environment organizations and regulatory bodies have heightened concerns about food and environmental safety.

The primary ingredients of feed can be traced back to the oilseed industry where, during processing, the oil (vegetable) is removed from the seed and the remaining oilseed cake or meal acts as the main protein source for animal feed. Once extracted, the cake and meal have historically been treated by formaldehyde and other chemical additives to modify the nutritional value while also acting as an antimicrobial that prevents the spread of viruses and bacteria such as salmonella and E. coli.

Over the last several years, an increasing number of jurisdictions worldwide have restricted or banned the use of chemicals such as formaldehyde, prompting operators to replace it with a variation of enzymes and heat treatment.

The challenge regulation

With the recent regulation changes concerning the treatment of animal feed, new challenges have emerged. Some methods, however, create a reaction between the animal feed and the added reagent. Excessive heating, meanwhile, often leads to protein that is less digestible – or, in many cases, a product that is not homogeneously heated. The heat treatment process is also energy intensive, resulting in significant operational costs and greenhouse gas emissions. Dutch-based co-operative Royal Agrifirm recognized an opportunity to create an efficient, safe and reliable method to treat the meal without chemicals while also increasing the nutritional value for its use as or for being processed into the animal feed. Core to the process of producing this new-generation rumen by-pass protein was what Agrifirm labelled as its Greenwave technology, a chemical-free process that heats the feed to approximately 130°C through radio frequency waves.

Agrifirm identified that to effectively reduce overall primary energy consumption in this production process, it still needed to pre-heat the product before using the RF technology – and then cool the product after the RF stage to ambient temperature for safe handling and storage. Also essential was the ability to recover energy from the hot product at the cooling stage, and then “upcycle” it for use back at the pre-heating stage.

Agrifirm connected with Solex Thermal Science, a world market leader in solids, liquids and gas heat exchange. The company has extensive experience with heating and cooling solid granular products in moving bed heat exchangers (MBHEs), as well as maximizing energy recovery in industrial operations.

What is an MBHE?

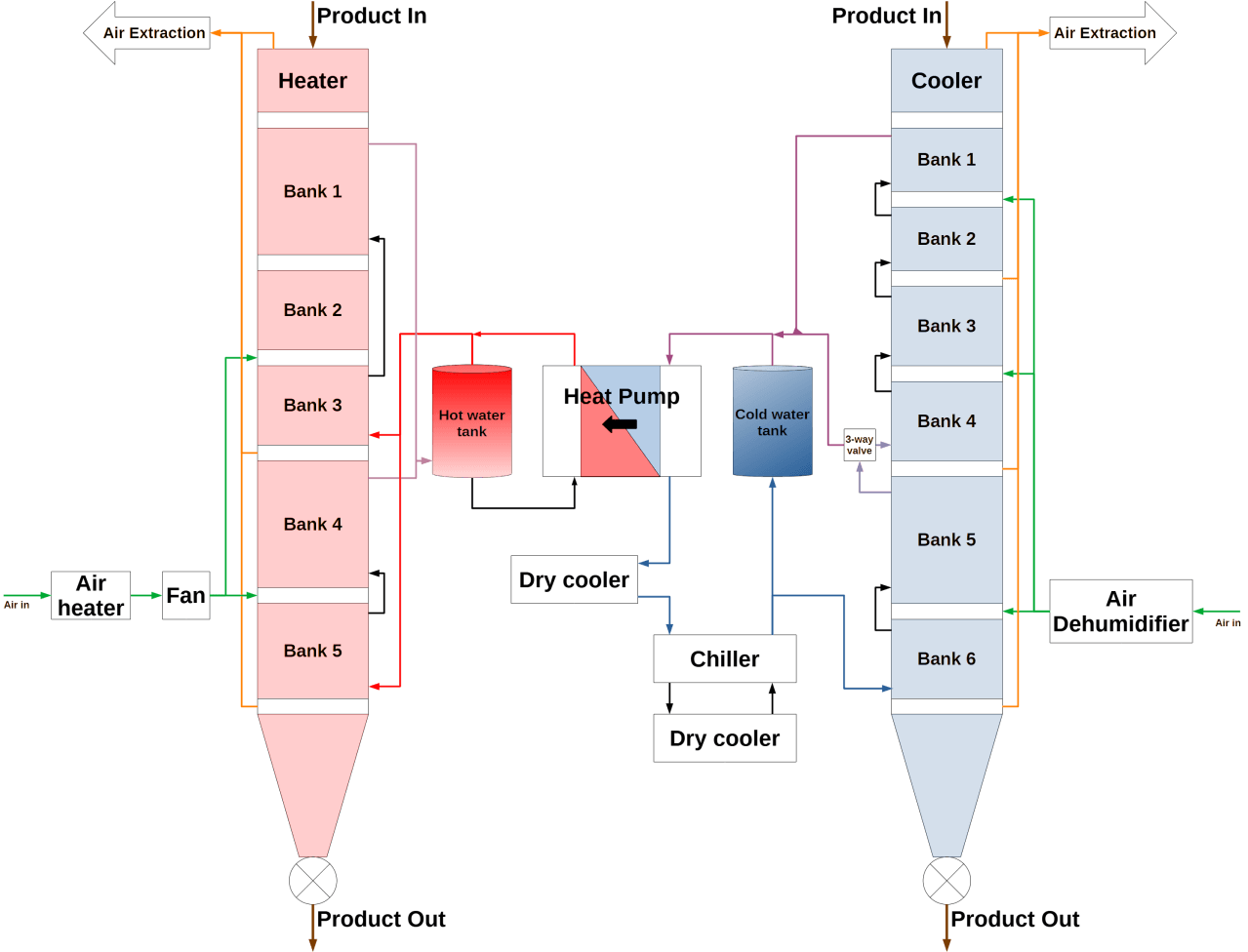

A moving bed heat exchanger (MBHE) allows for the exchange of thermal energy between solids (e.g., granules) and liquids through thermal conduction. It is characterized by a rectangular casing that is equipped with vertically positioned stainless steel pillow plates. The solids move continuously as a bed of product, driven by gravity between the plates. Inside the plates, a liquid heat transfer media flows countercurrent from the bottom of the unit to the top, ensuring optimized heat transfer. Given the product flow is driven by gravity and countercurrent to the liquid heat transfer media, the power consumption of an MBHE is low. It only requires power for the mechanical discharge (e.g., rotary valve for both preheater and cooler) and the circulation pump for the heat transfer liquid.

Pilot testing

For Agrifirm, the thermodynamic design of the MBHE was validated during several weeks of on-site pilot testing at the company’s plant in 2021. In addition to validating thermodynamic design, the tests focused on better understanding how the solids would behave in the MBHE – with special attention on flowability of the solids between the pillow plates. Flowability is primarily influenced by the density of the solids, as well as particle size distribution. Plate spacing that is too narrow could compromise the product flow by bridging and caking, which cannot be accepted for biodegradable products. In addition, the pilot tests analyzed how much moisture was released from the product in the void between the solids within the MBHE. This free moisture or relative humidity in the void leads to condensation and needs to be controlled in both coolers and heaters.

Condensation has the potential to create surface moisture on cold surfaces and/or particles, resulting in caking and bridging. The pilot tests revealed that a small amount of pre-heated air in the heater was enough to decrease the dew point of the air in the void and mitigate condensation. In the cooler, dehumidified air ensured the dew point was below the cooling water temperature in the plates. The pilot tests were encouraging and confirmed the MBHE as reliable, robust and therefore suitable to be used in Agrifirm’s process.

Implementation

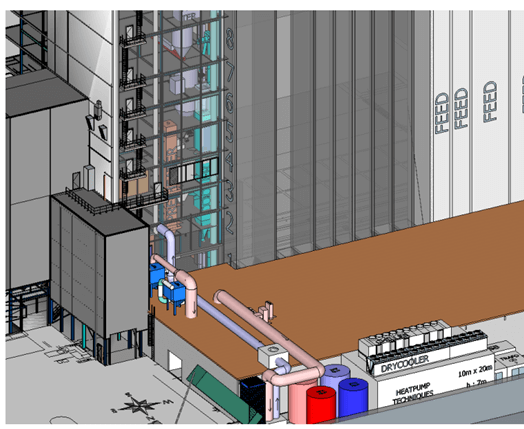

Agrifirm constructed the full-scale plant in Oss, The Netherlands in Spring/Summer 2023, followed by commissioning in September.

On-site, the raw product (soy and rape seed meal) is stored in silos. The product is conveyed to the pre-heater (MBHE) where it is preheated to about 70°C – after which the product is fed to the RF process where it receives the required thermal treatment to stabilize the product. The product is then conveyed from the RF equipment into the product cooler (MBHE) where it is cooled to approximately 30°C before it goes into storage. To recover energy from the hot product, the pre-heater and the cooler are connected via a heat pump. Driven by electrical energy, the heat pump creates a temperature gain from the water rejected from the cooler, and then “upcycles” it for use in the preheater. Because not all the energy in the cooling water can be used in the preheater, the system also includes a dry cooler and a chiller. The energy that cannot be used in the heat pump is rejected in the dry cooler. In case of high ambient temperatures, the dry cooler is assisted by a chiller to ensure the product can be cooled to the desired outlet temperature of around 30°C. The system’s flexibility ensures the entire process consumes as little primary energy as possible while still ensuring the product’s outlet temperature meets desired specifications.

Conclusion

Initial results from the first nine months of production have provided encouraging results, with performance optimization being achieved and the product consistently meeting required standards. The co-operation between Agrifirm and Solex on this unique process demonstrates that energy recovery from solids in MBHE can improve the energy efficiency of operations and reduce primary energy consumption.

Moreover, the Solex system has garnered praise for its alignment with Agrifirm’s sustainability goals, particularly in terms of energy consumption and carbon intensity.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in June 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.