In this 3-part series of articles, ODYSSEE Environnement presents feedback on using a bio-sourced product for anti-scaling treatment in cooling tower water, compared to conventional products.

By Amaury Buvignier, Frédéric Bertrand, Fabrice Chaussec, Xavier Labeille at ODYSSEE Environnement and Logan MANARANCHE at ODYSSEE USA INC.

I. Introduction

Water treatment programs strive to ensure the sustainability of water networks and thereby ensure the continuity of industrial production. These treatments are particularly aimed at preventing biofouling, corrosion, and scaling.

In line with the Millennium Development Goals adopted by the United Nations in 2008, a UN summit was held in 2015 during which 17 Sustainable Development Goals (SDGs) for the horizon 2030 were adopted by world leaders.

These goals aim to end poverty and build a more sustainable world based on three pillars: economic growth, social inclusion, and environmental protection.

In line with Sustainable Development Goals 13 and 15, which aim to combat climate change and promote sustainable development, efforts have been made to explore innovative alternatives to reduce the environmental impact of chemicals. A particular focus has been placed on developing natural or bio-sourced scale inhibitors. Currently, the available products for industrial water conditioning are mainly derived from mining (phosphates) or petrochemicals (polyacrylates). However, around 75% of the world’s phosphate production is concentrated in just three countries: Morocco, China, and the United States. These resources, primarily used in agriculture, are considered critical, and their depletion could potentially disrupt the global food balance. Polyacrylates, sourced from petrochemicals, present long-term environmental concerns.

While studies on natural scale inhibitors have been conducted since the 1950s, it has only been in the last decade or so that research in this area has intensified. Belarbi et al. [1,2], initiated research into new natural scale inhibitors for industrial water treatment. They hypothesized that plants traditionally used in the treatment of urinary lithiasis could also act as inhibitors of scale formation. Through electrochemical methods, they notably demonstrated that aqueous extracts of Paronychia argentea exerted an inhibitory effect on the formation of calcium carbonate precipitates. Additionally, Cheap-Charpentier et al. and Horner et al. have shown the potential effectiveness of plant extracts from Herniaria glabra, Spergularia rubra, or Parietaria officinalis in preventing scaling [3,4]. Based on these observations, previous published works by ODYSSEE Environnement focused on selecting plant sources and a specific eco-extraction method [5]. After many years of research, ODYLIFE, a bio-sourced antiscalant substance, was developed. Its development required overcoming various challenges, such as identifying and quantifying active substances, ensuring continuous quality control of plant raw materials, developing an eco-responsible industrial extraction process, and optimizing formulation. The culmination of ODYLIFE’s development is its recent deployment and in-situ testing, ensuring the product’s operational effectiveness.

In a 3 episodes series, we will highlight the importance of identifying tracers correlated with the antiscalant effectiveness of a plant extract, address the major challenge inherent in using a natural raw material of agricultural origin, namely, the variability in the quality of the supply. We will present the optimization approach of the industrial extraction process, developed by ODYSSEE Environnement, aimed at reducing the environmental impact of ODYLIFE as well as the regulatory limitations regarding the use of bio-sourced chemicals. Finally, we will discuss the experience gained from transitioning from a polyacrylate-based antiscalant treatment to ODYLIFE in a Cooling Tower (CT).

II. Materials and methods

II.1. Characterization of the extract

Characterization of plant extracts is carried out using two methods:

(i) quantification of dry residues;

(ii) quantification of an active molecule referred to as the “tracer active”.

The measurement of dry residues is performed by evaporating 2 mL of filtered plant extract in an aluminum dish with a diameter of 7 cm placed on a hot plate set at 130°C.

Quantification of the “tracer active” is carried out by UV-visible spectrophotometry. The optimized method allows quantification over a range of 0 to 100 mg/L with a precision of +/- 3 mg/L.

II.2. Extraction of the active material and yield

The eco-extraction method of plant dry matter (DM) developed was compared to conventional protocols for plant material extraction in a previous publication [5].

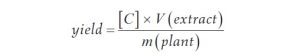

In the context of a single-step extraction, the yield can be calculated using the formula below.

With [C] being the mass concentration of extracted molecules, V(extract) the total volume of the extract, and m(plant) the dry mass of the added plant material.

With [C] being the mass concentration of extracted molecules, V(extract) the total volume of the extract, and m(plant) the dry mass of the added plant material.

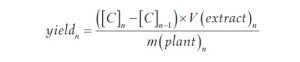

In the context of this study, extractions in multiple steps (by exhaustion or by enrichment) are performed (see Section III.2.1 Extraction). The yield at step n can then be calculated as follows.

With [C]n representing the mass concentration of extracted molecules at step n and [C]n-1 representing that at step n-1, V(extract)n the total volume of the extract at the end of step n, and m(plant)n the mass of plant material added at step n.

II.3. Characterization of the efficiency of a scale inhibitor

The efficiency measurement is conducted using chronoamperometry [1,6].

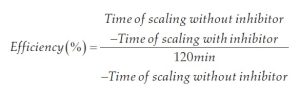

The experiments are conducted in a three-electrode cell. The reference electrode is a saturated calomel electrode (SCE), and the counter electrode is a platinum grid. The working electrode is a rotating disk electrode (RDE) with a carbon steel tip with a specific surface area of 1 cm². The rotation speed of the RDE is 1,000 rpm, and the temperature is maintained at 35°C. The electrolyte is osmosed water containing 0.500 g/L of CaSO4, 2 H2O; 0.60 g/L of MgSO4, 7 H2O; 0.420 g/L of NaHCO3. This results in a total hardness (TH) of 315 °f and a total alkalinity (TAC) of 25.0 °f. The measurement is performed using a Biologic SP-150 potentiostat, and the control and processing software is EC-Lab. The measurement is conducted over 120 minutes. The efficiency is calculated as follows:

III. Technological barriers: results and discussion

III. 1. Quantification

Traditional methods for quantifying active principles mainly rely on measuring dry residues (DR) or on chemical oxygen demand (COD) measurement.

In the absence of a purification phase, the extraction of plant materials leads to obtaining an extract containing a large number of molecules (proteins, fats, mineral salts, sugars, phenolic compounds, terpene compounds, etc.), not all of which necessarily contribute to scale inhibition [7].

In this context, ODYSSEE Environnement has developed a protocol to quantify the so-called “Tracer Active” in each plant extract.

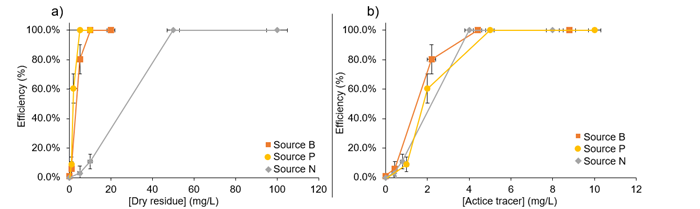

Figure 1 depicts the inhibitory efficacy of 3 antiscalant products as a function of dry residue concentration (a) or of a “Tracer Active” principle (b). Figure 1a shows that the efficacy of sources P and B reaches 100% at 5 mg DR/L (Dry Residue per Liter), while source N reaches 100% at most at 50 mg RS/L.

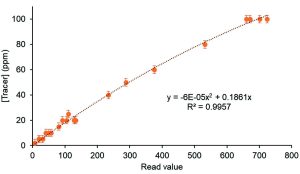

Figure 1b indicates that, regardless of the source, efficacy is achieved for at most 4 mg/L of “Active tracer” (or equivalent concentration in petro-sourced active molecule). The efficacy of a source is therefore correlated with its concentration of “Active tracers”. Figure 2 represents the calibration curve of the quantification method of the “Active tracer”, according to the method optimized by ODYSSEE Environnement.

Figure 2 highlights a strong correlation (R2 > 0.99) between the measured value and the theoretical concentration of the “Active tracer”.

Its simplicity and precision allow its use both in Quality control, in laboratory R&D analyses, and in “field” monitoring (post-harvest, monitoring of on-site installations, etc.), just like other classic water analyses. This method allows, on the one hand, control of the content of “Active tracers” at each stage of the life cycle of ODYLIFE and, on the other hand, ensures optimal inhibitory effectiveness against scaling.

Furthermore, this method allows for adjusting the proportion of plant extracts in the final ODYLIFE product formulas based on their “Active tracer” content, thus ensuring consistent product quality.

III. 2. Supply control

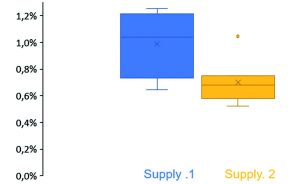

The use of plant-based raw materials leads to a high variability in composition depending on growing conditions (soil, climate, inputs, etc.), variety, harvested part, growth stage, etc. [8–10]. Figure 3 shows the variability of mass concentrations of the “Active tracer” observed for 2 successive supplies of the same raw material (source M) composing ODYLIFE.

Figure 3, derived from 6 samples per supply, indicates a higher proportion of “Active Tracer” in supply #1 (~10%) compared to supply #2 (~7%). Additionally, a significant dispersion around the mean is observed, particularly for supply #1, indicating that the raw material harvested within the same plot and at the same time may exhibit significant heterogeneity.

In this case, for the same quantity of raw material produced and extracted, supply #1 yields an extraction efficiency of active principle 30% to 40% higher compared to supply #2.

Thus, for the same amount of energy expended to extract a given source, the higher the extraction efficiency of the active principle, the greater the economic and environmental impact reduction.

Conclusion

After establishing the formula of ODYLIFE in the laboratory, its industrialization required the development of a specific quantification method, based on the detection of active tracer molecules by spectrometry. The correlation between the concentration of the tracer and the inhibitory effectiveness of scale formation was verified for different selected sources. Furthermore, the evaluation of the inhibitory potential of a plant source (through quantification method) allowed for improving the quality of plant raw materials by using the sources richest in active principles (increasing from 7% to 10% mass of active molecules per dry residue), thereby enhancing the ecological and economic efficiency of ODYLIFE.

In the next episode, we will present the optimization approach of the industrial extraction process, developed by ODYSSEE Environnement, aimed at reducing the environmental impact of ODYLIFE (Life Cycle Analysis, Ecotoxicity) as well as the regulatory limitations regarding the use of bio-sourced chemicals.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in June 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.