In this 3-part series of articles, ODYSSEE Environnement presents feedback on using a bio-sourced product for anti-scaling treatment in cooling tower water, compared to conventional products.

By Amaury Buvignier, Frédéric Bertrand, Fabrice Chaussec, Xavier Labeille at ODYSSEE Environnement and Logan MANARANCHE at ODYSSEE USA INC.

PLEASE NOTE: Part 1 can be read here

I. Introduction

After highlighting the importance of identifying tracers correlated with the antiscalant effectiveness of a plant extract, we will address the major challenge inherent in using a natural raw material of agricultural origin, namely, the variability in the quality of the supply. We will present the optimization approach of the industrial extraction process, developed by ODYSSEE Environnement, aimed at reducing the environmental impact of ODYLIFE as well as the regulatory limitations regarding the use of bio-sourced chemicals.

II. The lifecycle analysis and ecotoxicity: results and discussion

II.1. Extraction

Previous studies have shown that the choice of eco-extraction method affects its yield [5].

In this new study, the objective is to investigate if the environmental impact of the extraction process can be improved. Two extraction methods were tested:

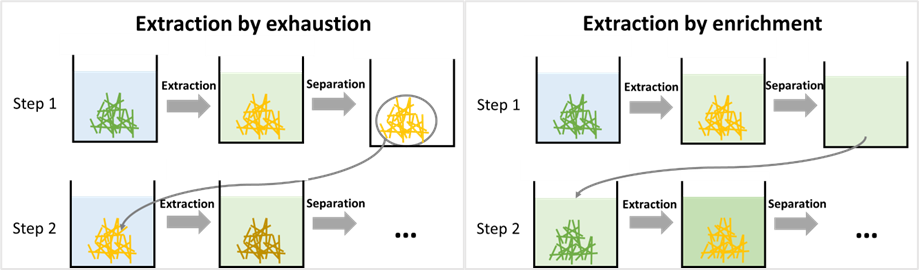

- Progressive depletion of the raw material and complete renewal of the extraction solvent at each step;

- Enrichment of the extract by complete renewal of the material to be extracted at each step.

Figure 1 illustrates the two extraction methods described above.

In the exhaustion extraction method, the solvent is renewed at each stage, while in the enrichment extraction method, it is the dry matter that is renewed at each step. Regardless of the method or extraction step, the Solid/Liquid ratio is 10% by mass.

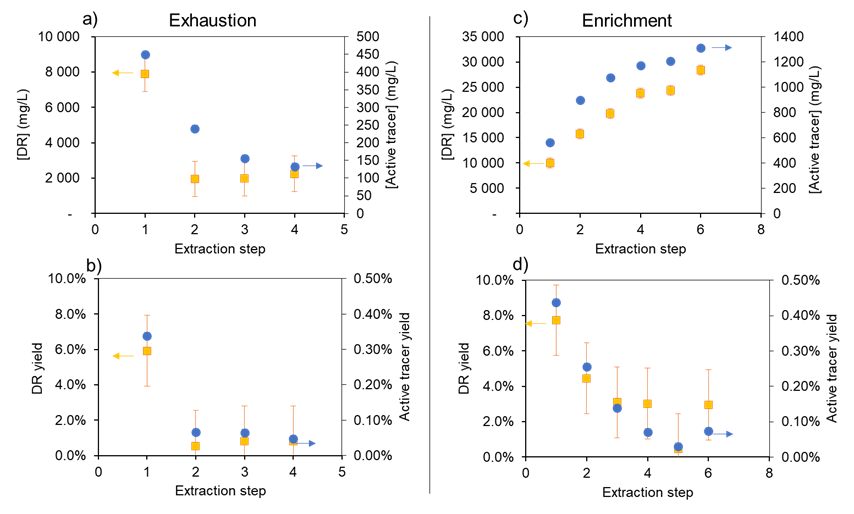

Figure 2 shows the evolution, step by step, of various parameters measured during an exhaustion extraction (a) and (b) and during an enrichment extraction (c) and (d).

Figure 2a shows that during an exhaustion extraction, the first step allows extracting approximately 450 mg/L of “Active tracer”, compared to only 250 mg/L in the second step. The extraction yield, as shown in Figure 2b, then decreases from 0.35% in step 1 to 0.07% in step 2. The discrepancy between the evolution of “Active tracer” and RS is explained by the significant uncertainty in the measurement of residual solids due to the low concentrations measured, and the difference in solubility between the tracer compound and other constituents of the raw material. The “Active tracer,” easily extractable in the extraction solvent, is more rapidly “exhausted” during extraction than other compounds in the raw material. Figure 2c shows that during an enrichment extraction, the concentration of “Active tracer” increases rapidly between steps 1 and 4 (from 564 to 1171 mg/L), reaching a plateau beyond the 6th extraction (1310 mg/L). Additionally, the yield decreases from 0.44% in step 1 to 0.07% in step 4, then remains between 0.03% and 0.07% between steps 4 and 6.

Thus, from the second step of an exhaustion extraction, the yield is divided by 5. The majority of active principles are extracted during the first step. During an enrichment extraction, there is a change in slope in the curves of “Active tracer” concentration and RS yield evolution from step 3 or 4. Beyond this inflection point, the extraction yield stabilizes. This stabilization of the extraction yield observed from step 4 onwards is probably due to the progressive saturation of the solution. Conducting a second series of enrichment extractions confirmed this inflection point around steps 3 and 4 and the attainment of a plateau from step 6 to step 9 (data not shown).

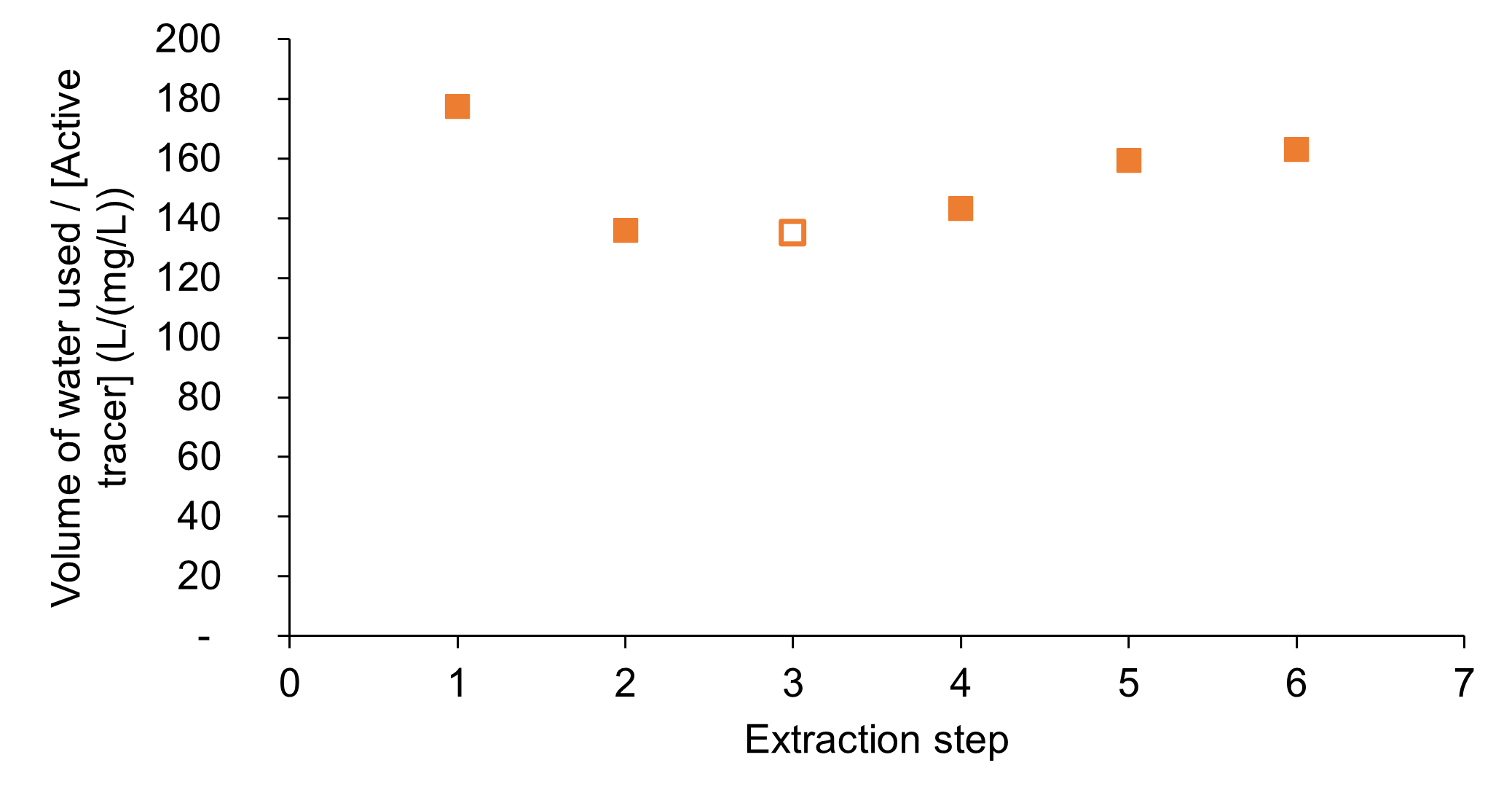

The environmental impact of the extraction process is mainly related to the energy required for heating the solvent during extraction and for the solvent evaporation to obtain a stable concentrate. Regarding the extraction phase, enrichment appears to be more efficient as it allows for the reuse of the solvent and therefore the recovery of the heat it contains. However, one may question the profitability of enrichment extraction at each step. Therefore, Figure 3 presents the evolution, step by step, of the volume of water used per mg/L of “Active tracer” during an enrichment extraction.

Figure 3 shows a decrease in the volume of water (L) per mg/L of “Active tracer” extracted from step 1 to step 3 (177 L/(mg/L) and 135 L/(mg/L) respectively), followed by an increase in this value up to step 6 (163 L/(mg/L)). The minimum of the curve is reached at step 3, where the least amount of water is used to extract the maximum amount of active ingredient.

Regarding the concentration phase, the more concentrated the initial extract, the less energy is required for the concentration process. Therefore, step 3 appears to be the most interesting as it leads to a more concentrated extract while minimizing the amount of water used. It is estimated that enrichment extraction could reduce energy consumption by 50% during the concentration step, and by approximately 25% during the extraction step.

II.2. Lifecycle analysis

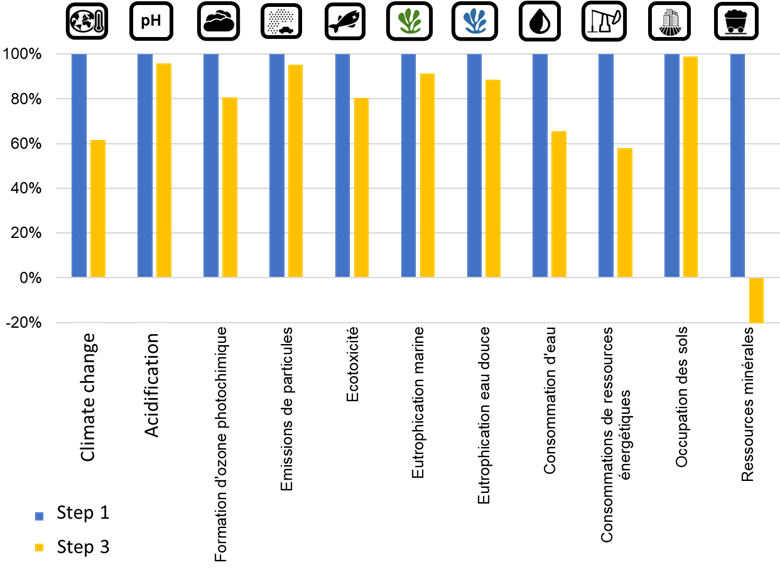

The environmental impact of a natural extract is not limited to the volume of solvent needed for extracting the raw material or the amount of energy required to heat it. It must be studied comprehensively across the entire life cycle of the product. Based on mid-point indicators for an analysis scope ranging from agricultural production attributable to ODYLIFE to factory output (cradle-to-gate), we compared, as shown in Figure 4, the life cycle of an extraction based on the number of enrichment extraction steps (1 step or 3 steps).

We observe, in Figure 4, an overall decrease in the environmental impact of ODYLIFE when transitioning from 1 to 3 extraction steps. This reduction is primarily due to the optimization of the amount of water needed to extract the active ingredients.

Beyond optimizing technical parameters, ODYSSEE Environnement is committed to a comprehensive eco-responsible approach by favoring local supply chains and collaborating with local partners, from cultivation (stimulation, creation of new outlets, and promotion of French agriculture) to the extraction of ODYLIFE. Additionally, the sludge resulting from the extraction process is reused for spreading, thus establishing a circular economy through ODYLIFE.

II.3. Ecotoxicity

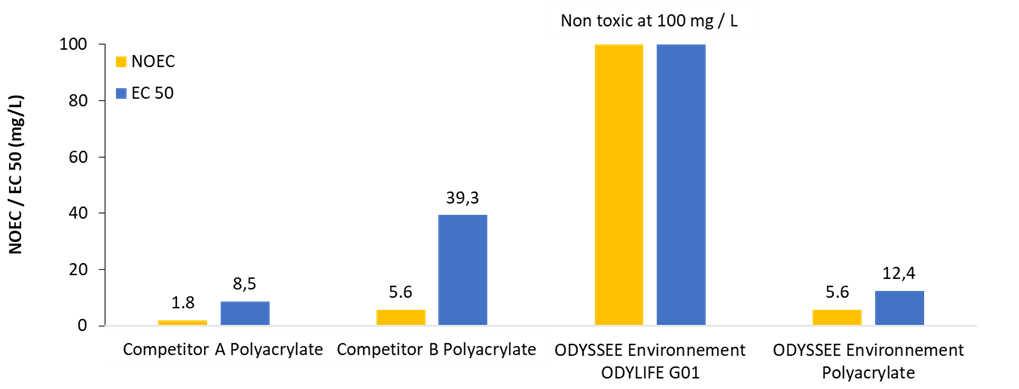

The natural origin of ODYLIFE does not imply its safety [11]. Ecotoxicological tests were conducted to study the ecotoxicity of the ODYLIFE product on the embryo-larval development of bivalves (oysters). Figure 5 represents the No Observable Effect Concentration (NOEC) and the Median Effective Concentration (EC50) for chemical solutions based on ODYSSEE Environnement’s polyacrylates and competitors, as well as ODYLIFE.

Figure 5 indicates that products based on polyacrylates have a NOEC and an EC50 lower than 5.6 mg/L and 39.3 mg/L, respectively. In contrast, ODYLIFE shows no toxicity over the entire range of tested concentrations (up to 100 mg RS/L). ODYLIFE appears to be more than 20 times less impactful on the embryo-larval development of bivalves than polyacrylate-based products. Furthermore, since ODYLIFE is derived from a natural source, unmodified chemically, and non-toxic, according to REACH regulations, it is exempt from a safety data sheet. ODYSSEE Environnement also aims to update current regulations on discharges to revise the parameter related to the COD threshold, especially when the product used is natural and non-concerning.

In conclusion, the industrial production of ODYLIFE required the development of a specific method for characterizing the active ingredient representative of the scale inhibition efficacy. This allowed for the characterization of raw materials and the selection of plant sources rich in active molecules, optimizing both the environmental impact and the economic profitability of ODYLIFE. Similarly, industrial scaling provided an opportunity to optimize the extraction process established previously in the laboratory, making it more ecological and economical by choosing a three-step enrichment extraction. Finally, ecotoxicological tests demonstrated the safety of ODYLIFE and its exemption from Safety Data Sheets under REACH regulations.

III. Conclusion

After establishing the formula of ODYLIFE in the laboratory, its industrialization required the development of a specific quantification method, based on the detection of active tracer molecules by spectrometry. The correlation between the concentration of the tracer and the inhibitory effectiveness of scale formation was verified for different selected sources. Furthermore, the evaluation of the inhibitory potential of a plant source (through quantification method) allowed for improving the quality of plant raw materials by using the sources richest in active principles (increasing from 7% to 10% mass of active molecules per dry residue), thereby enhancing the ecological and economic efficiency of ODYLIFE.

Similarly, the environmental impact was reduced by an average of 20% by transitioning from a single extraction stage to three successive extraction stages by enrichment. Finally, due to its nature, ODYLIFE is exempt from REACH regulations (no SDS required), and it poses no environmental hazards compared to conventional products.

In the next episode, we will discuss the experience gained from transitioning from a polyacrylate-based antiscalant treatment to ODYLIFE in a Cooling Tower (CT).

References

- Z. Belarbi, J. Gamby, L. Makhloufi, B. Sotta, B. Tribollet, Inhibition of calcium carbonate precipitation by aqueous extract of Paronychia argentea, Journal of crystal Growth. 386 (2014) 208–214. https://doi.org/10.1016/j.jcrysgro.2013.09.048.

- Z. Belarbi, B. Sotta, L. Makhloufi, B. Tribollet, J. Gamby, Modelling of delay effect of calcium carbonate deposition kinetics on ro-tating disk electrode in the presence of green inhibitor, Electrochimica Acta. 189 (2016) 118–127. https://doi.org/10.1016/j.electac

ta.2015.12.08.9 - H. cheap-charpentier, D. Gelus, N. Pécoul, H. Perrot, J. Lédion, O. Horner, J. Sadoun, x. cachet, M. Litaudon, f. Roussi, Antiscalant properties of Spergularia rubra and Parietaria officinalis aqueous solutions, Journal of crystal Growth. 443 (2016) 43–49. https://doi. org/10.1016/j.jcrysgro.2016.03.020.

- O. Horner, H. cheap-charpentier, x. cachet, H. Perrot, J. Lédion, D. Gelus, N. Pécoul, M. Litaudon, f. Roussi, Antiscalant properties of Herniaria glabra aqueous solution, Desalination. 409 (2017) 157–162. https://doi.org/10.1016/j.desal.2017.01.028.

- B. Printz, f. chaussec, Vers un traitement naturel ou bio-sourcé de l’entartrage des réseaux industriels, in: Poitiers, 2018.

- f. Hui, J. Lédion, Evaluation methods for the scaling power of water, Journal Européén d’hydrologie. 33 (2002) 55–74.

- P. Goetz, Plaidoyer pour la tisane médicinale, De La Recherche A La Pratique. 2 (2004) 8–15. https://doi.org/10.1007/s10298-004-0004-7.

- J. Andrieu, c. Demarquilly, J.-M. Boissau, H. Bousquet, J. Jamot, M. Jailler, L. L’Hotelier, Valeur alimentaire du maïs fourrage. II. – Influ-ence du stade de végétation, de la variété, du peuplement, de l’enrichissement en épis et de l’addition d’urée sur la digestibilité et l’ingestibilité de l’ensilage de Maïs., in: EDP Sciences, 1974: pp. 1–25.

- L. Gueguen, Etude de la composition minérale de quelques espèces fourragères. Influence du stade de développement et du cycle de végétation, (1959).

- P. Martin-Prével, G. Montagut, J. Godefroy, J.-J. Lacoeuilhe, Essais sol-plante sur bananiers : une méthode d’étude de la fertilité, (1965).

- O.c. Seremet, O.T. Olaru, c.M. Gutu, G.M. Nitulescu, M. Ilie, S. Negres, c.E. Zbarcea, c.N. Purdel, D.A. Spandidos, A.M. Tsatsakis, M.D. coleman, D.M. Margina, Toxicity of plant extracts containing pyrrolizidine alkaloids using alternative invertebrate models, Mol Med Rep. 17 (2018) 7757–7763. https://doi.org/10.3892/mmr.2018.8795.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in July 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.