In this 3-part series of articles, ODYSSEE Environnement presents feedback on using a bio-sourced product for anti-scaling treatment in cooling tower water, compared to conventional products.

By Amaury Buvignier, Frédéric Bertrand, Fabrice Chaussec, Xavier Labeille at ODYSSEE Environnement and Logan MANARANCHE at ODYSSEE USA INC.

PLEASE NOTE: Part 1 can be read here, Part 2 can be read here

I. Introduction

In the previous 2 articles, we highlighted the importance of identifying tracers correlated with the antiscalant effectiveness of a plant extract, addressing the major challenge inherent in using a natural raw material of agricultural origin, namely, the variability in the quality of the supply. We presented the optimization approach of the industrial extraction process, developed by ODYSSEE Environnement, aimed at reducing the environmental impact of ODYLIFE as well as the regulatory limitations regarding the use of bio-sourced chemicals. In this article, we will discuss the experience gained from transitioning from a polyacrylate-based antiscalant treatment to ODYLIFE in a Cooling Tower (CT).

II. Experience feedbacks

II.1. Site selected

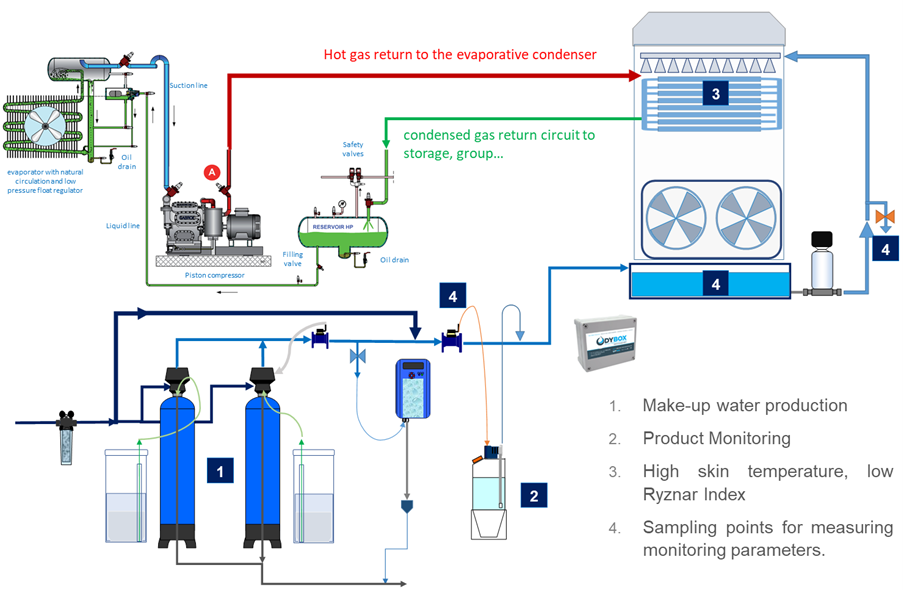

ODYLIFE having been validated in the R&D laboratory, the final step is to test it at a 1:1 scale by applying it to real operating cooling towers. To do this, we began by substituting ODYLIFE for its “operational” equivalents in our formulations to validate the compatibility of the solutions. The substitution led to the presence of a very low proportion of fi ne particles in solution but did not alter the stability of the different formulations containing ODYLIFE, nor their aspect. Several sites in France with water cooling applications and different water qualities have been chosen to deploy ODYLIFE industrially. The selected installations all have circuits that can be assimilated to the schematic diagram represented in Figure 1. On each of the tested circuits, the same observations were made, leading to the same conditions. Therefore, this article will focus on one site only, site G.

The conditioning strategies follow the guidelines of the regulatory French framework ICPE 2921, which emphasize the need to maintain surface cleanliness, performance, and equipment integrity while controlling microbial activity in the fluid. As monitoring indicators, we use the Ryznar Index (I.Rz) and the Saturation Index (SI). Although highly debated, the I.Rz is often indispensable in the profession as an indicator, and its association with SI provides a very good characterization of water’s scaling potential.

The temperature used for calculating the two indices is the most important measurement taken from the water network. Generally, it is located at the top of the evaporator, where a high skin temperature induces parameters particularly favorable to scaling (low I.Rz). Water analyses were conducted every 2 weeks, from 13 weeks before the switch from the conventional product to ODYLIFE until 11 weeks after the substitution. Surface conditions were also regularly monitored. Analytical monitoring was reinforced and supplemented by the surveillance of key parameters (measurement of additional parameters such as BOD5, COD, etc.) continuously and remotely using the dedicated ODYBOX-ODYSECURE solution.

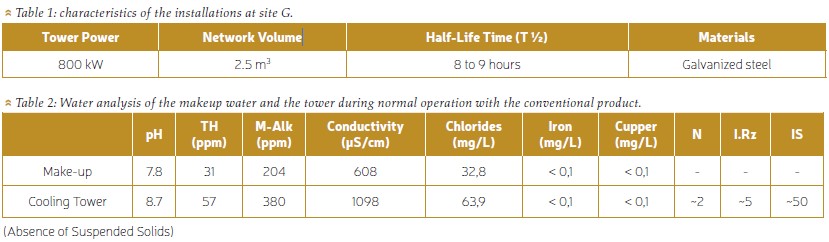

Table 1 presents the characteristics of the installation at site G. Table 2 presents the water analysis of the makeup water and the circuit with the conventional product for site G. The calculations of I.Rz and SI in the TAR depend on the fluid temperature, which was considered to be 60°C (140°F), the maximum value recorded in the network.

II.2. Surface condition before and after substitution

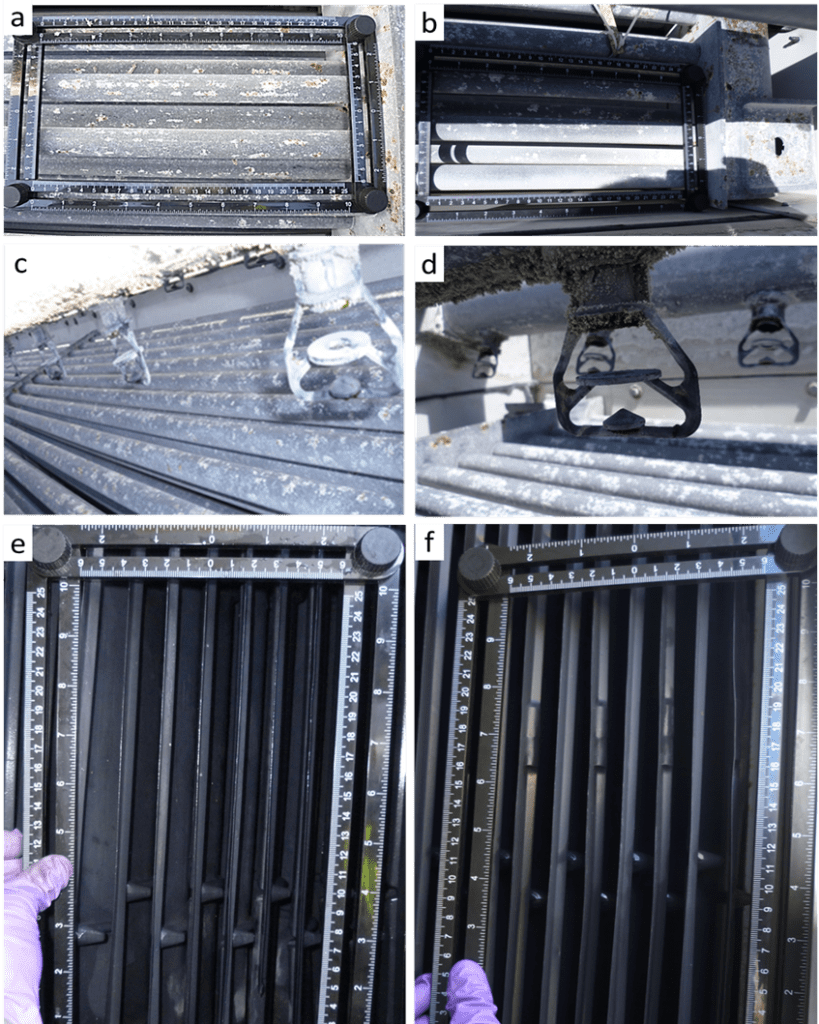

On this site, the towers are cleaned twice a year, this biannual scheduling ensures detailed monitoring of the evolution of surface conditions. The switch from the conventional product to ODYLIFE took place on March 16th, 2020. Technical shutdowns occurred in early December (4 months before the change of conditioning product) and early June (3 months after). The evolution of surface conditions during the technical shutdowns at site G is presented in Figure 2.

We observe in Figure 2a (Nov. 2019) and b (June 2020) the maintenance of surface conditions, with no deposition formation observed on the upper tubes. In Figure 2c (Nov. 2019) and d (June 2020), surface conditions are maintained with no deposition formation on the nozzles (historical deposits, in place, non-evolving). Figure 2e (Nov. 2019) and f (June 2020) show very clean surfaces with no deposition formation and absence of salts between the trickle lamellas of the packing. In conclusion, three months after switching from the conventional product to ODYLIFE, there is no significant modification in surface conditions. The system’s integrity is maintained.

II.3 Monitoring

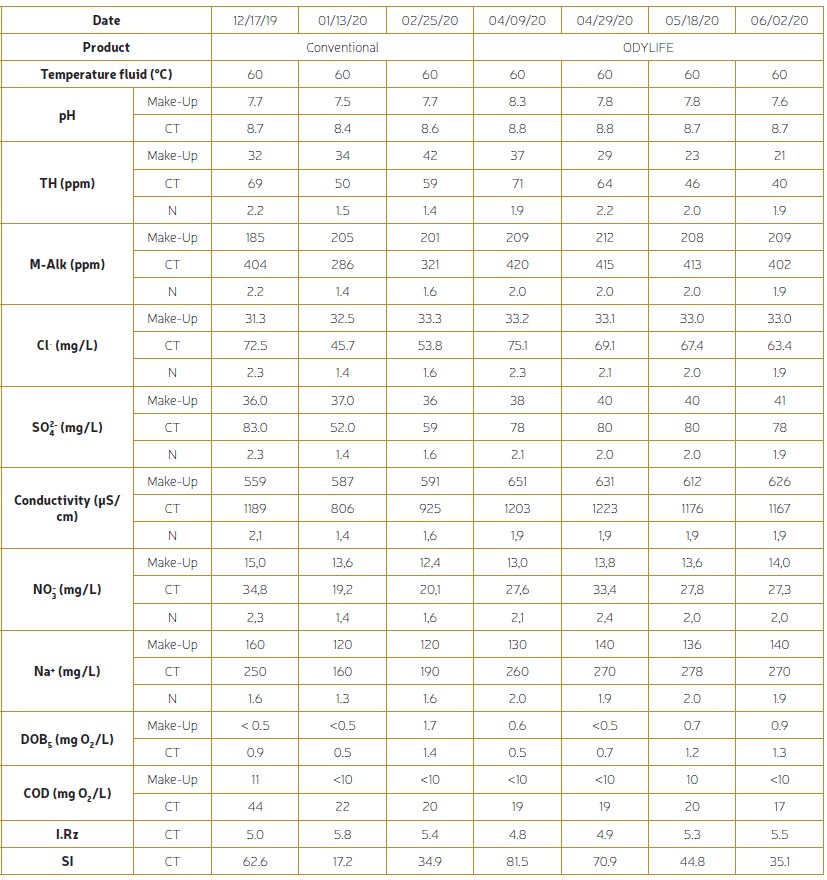

Water quality at the installation was monitored throughout the in-situ test. In addition to standard parameters, concentrations of sulfate, nitrate, BOD5, and COD were measured. Table 3 shows the evolution of water quality based on the analysis date.

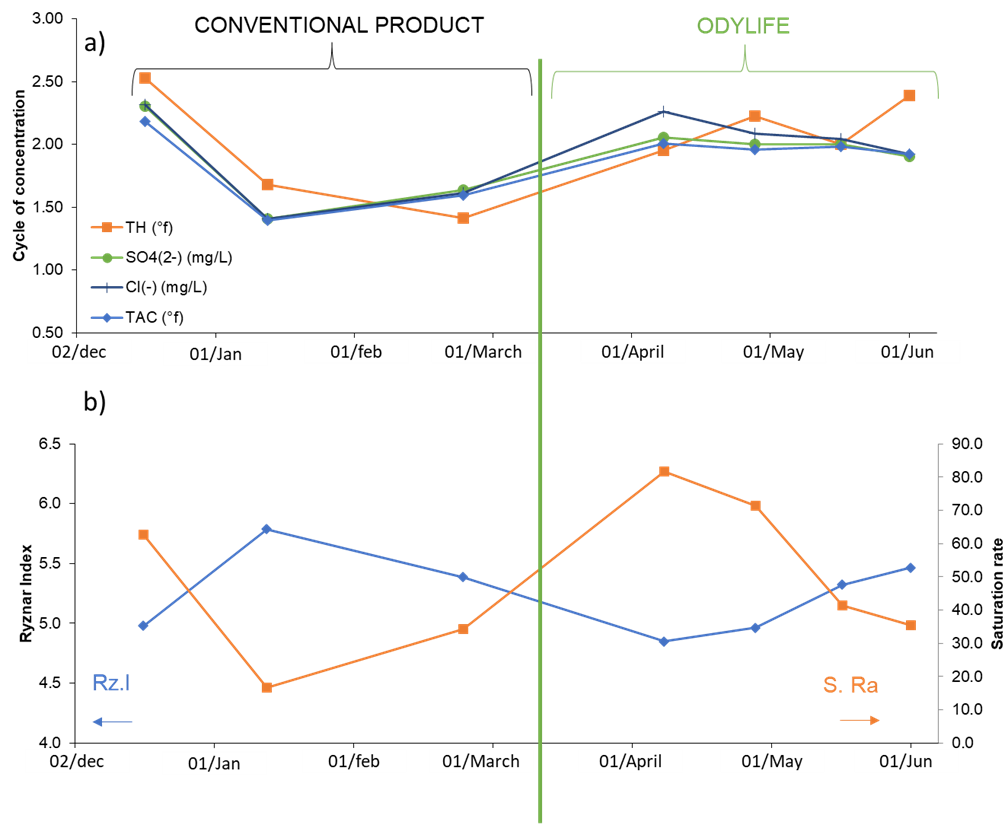

Figure 3 shows the evolution a) of the concentration factor (TH, TAC, Chlorides, Sulfates), b) of the I.Rz and SI, over time for site G. The central vertical line corresponds to the switch from the conventional product to ODYLIFE (March 16th 2020). We observe from Table 3 constant values for the makeup water. Between the first and second analysis, the client decreased the concentration in the tower, which explains the decrease in concentration factors (N) (Figure 3a) between early December and early January.

During the analyses with the conventional product, the concentration factors were around 1.5 to 2.0 when switching to ODYLIFE. Despite the increase in system concentration between February 25th and April 9th, the system integrity was preserved with ODYLIFE conditioning. Additionally, in Figure 3b, we see an I.Rz oscillating between 4.8 and 5.8 for the TAR. The SI, on the other hand, oscillates between 20 and 80. The tests show that a simple substitution of the petrosourced antiscalant with ODYLIFE, without changing the operating conditions of the network, remains transparent to operation. The next step for this site will be to increase the concentration rate to reduce the I.Rz to values close to 4.2.

III. Conclusion

During the deployment of ODYLIFE on industrial sites, the integrity of the networks was maintained despite an increase in the concentration factor. Surface conditions are also preserved, even in the most vulnerable areas. One difference resulting from the substitution of conventional products by ODYLIFE is the slight increase in the proportion of readily biodegradable DBO5 in the effluent water.

The deployment of ODYLIFE is part of a concept that respects industrial ecology: offering industrialists a technical solution that is equivalent but in line with today’s environmental challenges. Through the ODYLIFE program, Industrial Water Companies continue to reflect globally on the field of water conditioning and advances in the creation of industrial sectors in green chemistry.

These sectors are founded and organized according to the principles of the circular economy, and it is this approach that has enabled the networking of French actors, ranging from farmers to users of the commercial product. The green revolution is now underway, integrating the knowledge of sectors engaged in this evolution, tools from the digital world, eco-design, biosafety: it is the approach of hydroethics, allowing us to progress and concretely envision the objectives of ecological transition in the industry. The path we are forging is taking shape with ODYLIFE.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.