Weld overlay and cladding are widely used applications for adding a protective metallic layer to a substrate base material, where the cladding material has higher preferable properties, mainly corrosion protection. This is a cost-effective solution that can replace fabricating the entire component from high-alloying material. The required material strength to withstand applied loads and required thermal conductivity and fabricability are ensured by a less costly substrate metal. In this article, the main aspects of the correct application of cladding will be explored, covering design, fabrication, inspection, and in-service considerations.

Baher Elsheikh, Lead Mechanical Engineer – SABIC

Advantages of using cladding applications

Cladding applications offer several advantages, making them a popular choice in various industries. Here are some key benefits:

Corrosion Resistance

Cladding directly addresses corrosion concerns by adding a layer of material with high corrosion resistance, avoiding the need to upgrade the full thickness due to cost or better fabricability reasons.

Erosion Resistance

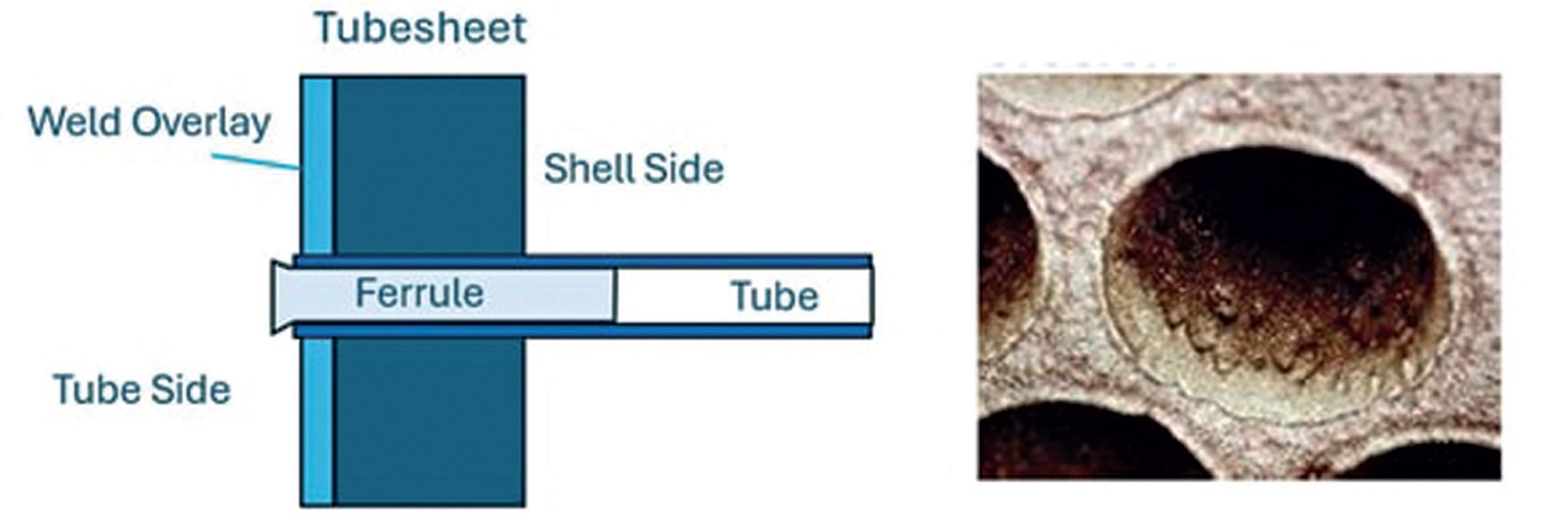

In specific situations, localized erosion can be a major concern, such as in the tube entrance area, especially in Flow Accelerated Corrosion (FAC) conditions. FAC is metal loss that occurs in carbon steel equipment when the normally protective magnetite (Fe3O4) layer is dissolved into a flowing stream of water or water and steam. Cladding the tubesheet and using insert ferrules at the entrance of tubes can mitigate the threat of FAC and erosion at these critical locations.

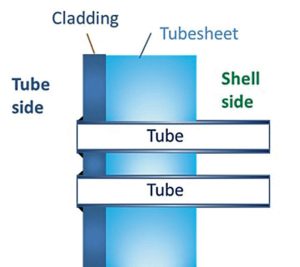

Avoiding dissimilar welds (DW) between tubes and tubesheet

In applications where the tube material is different from the tubesheet material, DW can be a concern. Cladding the tubesheet with a material matching the tube material can avoid DW issues, including thermal stresses, galvanic corrosion, and quality assurance challenges during weld applications.

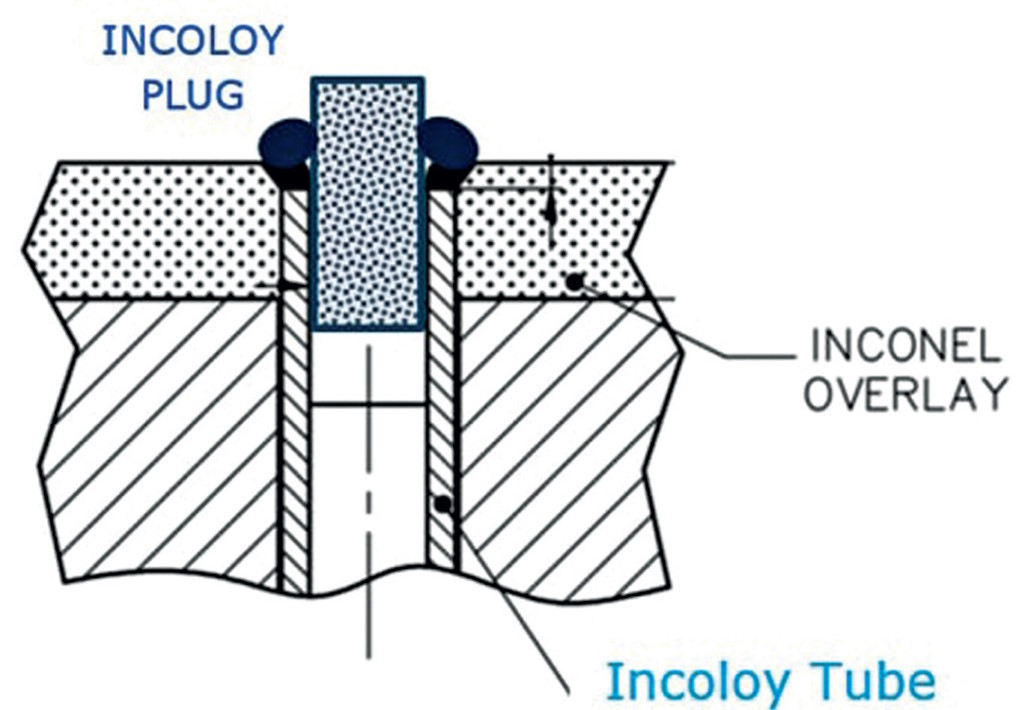

Avoiding the need for post weld heat treatment (PWHT) for in-service tube plugging

For tubesheets fabricated from materials requiring PWHT, such as Cr-Mo steels, when tube plugging is required after in-service degradation, plug welds should be subjected to PWHT. This is a challenging activity due to the high heat sink from thick tubesheets and the susceptibility of the ligaments in the tubesheets to high thermal stresses. By applying a cladding layer to the tubeside face of the tubesheet, plugs can be welded to the clad, and plug material can be selected to match the clad material, avoiding the need for PWHT.

Resistance to hydrogen diffusion

In hydrogen service, cladding reduces hydrogen diffusion to and from the substrate material. Although it does not eliminate hydrogen diffusion, it is an effective mitigation technique. The low diffusivity of hydrogen in stainless clad or similar overlay materials used for corrosion protection results in an effective pressure of hydrogen at the clad/ overlay-to-base metal interface (bond line) that is lower than that of the process stream. This can result in a significant reduction in the effective hydrogen partial pressure experienced by the underlying steel below the cladding.

Resistance to nitriding

Nitriding is the formation of a hard, brittle surface layer on some alloys due to exposure to high-temperature process streams containing high levels of nitrogen compounds such as ammonia or cyanides, particularly under reducing conditions. Cladding with nickel alloy material is successfully used for protection against nitriding. An example of this is the weld overlay application on the shell side of an effluent cooler in the synthesis loop in ammonia plants, which is beneficial in resistance to nitriding and hydrogen embrittlement.

and cladding.

Application technologies

There are different techniques and technologies used in cladding applications, among which three are the most common:

Hot roll bonding

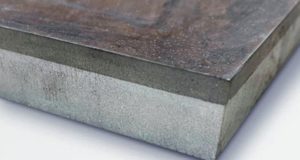

Produced when a steel mill heats the steel and corrosionresistant alloy together and rolls them as one package. The rolling, under high temperature and pressure, causes the two metals to clad together. It is generally accepted that a roll bond clad plate has the lowest bond shear strength of the three techniques described in this article. It is the major production method for stainless-clad steel plates. Hot roll bonding accounts for more than 90% of the clad plate production worldwide.

Explosion bonding

Explosive bonding uses the very-short duration, high-energy impulse of an explosion to drive two surfaces of metal together, simultaneously cleaning away surface oxide films and creating a metallic bond. It resists the most aggressive hydrogen charging scenarios.

Weld overlay

Weld overlay is a fusion deposition of corrosion-resistant alloy onto a steel or alloy steel substrate. Usually, weld overlay is done in place, after the pressure vessel has been through many of the fabrication steps, but not always. In many cases, dilution concerns necessitate the use of ‘butter passes’ and over-alloying in an attempt to overcome the issues of dilution.

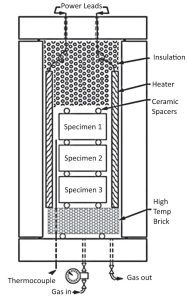

Special care for application in hydrogen service

Clad disbonding tests should be performed on any 1.25Cr-1/2Mo and 1Cr-1/2Mo vessel that is in high-pressure hydrogen service that may be subjected to rapid cool down conditions from service. Vessels that have experienced disbonding have been subjected to a rapid shut down. The rapid shut down does not allow hydrogen diffusion before reaching ambient temperature. Hydrogen disbonding tests on the proposed overlay weld procedures shall be done per ASTM G146, at the testing conditions defined by the purchaser.

Bimetallic (duplex) tubing

Bimetallic tubing consists of two concentric tubes of different materials for applications with various corrosion resistance on the shell and tube sides. An example of this is the bimetallic tubes used in strippers in urea strippers, which have an external stainless tube and internal zirconium tube for resistance to highly corrosive carbamate. Another example is the Omega bondTM tubes used in urea stripper tubes fabricated from an inner zirconium tube and an outer titanium tube.

Cladding thickness

In general, design codes and company specifications do not permit using the clad thickness as additional thickness to resist pressure but rather treat it only as corrosion allowance. For weld overlay application, the cladding thickness shall be sufficient to have an acceptable depth of the required chemical composition (1.5 mm per API Std. 660) considering the dilution at the interface with the base metal.

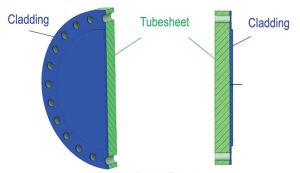

Cladding and weld overlay thickness of the tubesheet in shell and tube heat exchangers depends on the type of tube-to-tubesheet joints (strength welded or expanded). When the tubes are expanded only to the tubesheet, the required clad thickness is higher compared to the case when the tubes are welded to the tubesheet. This is to provide the proper distance to expand the tube to the cladding material and prevent the ingress of the corrosive media to the base metal of the tubesheet. Note: expansion grooves, when applicable, should be in the tubesheet base metal, not in the cladding layer.

In API 660, the cladding (including weld overlay) thickness at the tube side face of a tubesheet shall not be less than 10 mm when tubes are expanded only, and 5 mm when tubes are welded to the tubesheet.

In TEMA, for classes R and B, the nominal cladding thickness at the tube side face of a tubesheet shall not be less than 7.8 mm when tubes are expanded only, and 3.2 mm when tubes are welded to the tubesheet. The nominal cladding thickness on the shell side face shall not be less than 9.5 mm.

In Hydrogen service, special consideration for the required effective clad thickness which can reduce the effective Hydrogen partial pressure to desired values which can eliminate the risj of hydrogen attack to the base metal.

Corrosion resistant alloy clad and weld overlay are not considered as pressure retaining. When calculating the thickness of the pressure retaining components only the base metal should be considered.

Repair and joint preparation for clad and weld overlaid steel

Cladding shall be stripped back for a minimum distance of 3/16 in. (4.8 mm) from the edge of the weld bevel. The cladding edge shall be rounded with a minimum radius of 1/16 in. (1.5 mm) or tapered at a minimum angle of 30°. For carbon and low-alloy steel backing material the stripped-back area shall be etched with either a nitric acid or copper sulfate solution to ensure complete removal of cladding.

Prior to back cladding butt joints, Care shall be taken to avoid cross contaminating the cladding and backing material weld metal.

Conclusion

Cladding applications in shell and tube heat exchangers offer several advantages, including corrosion and erosion resistance, avoidance of dissimilar welds, and resistance to hydrogen diffusion and nitriding. Various application technologies, such as hot roll bonding, explosion bonding, and weld overlay, are used to apply cladding. Special care is needed for applications in hydrogen service, and bimetallic tubing can be used for applications with various corrosion resistance requirements. Cladding thickness should be sufficient to provide the required chemical composition and prevent the ingress of corrosive media to the base metal of the tubesheet. Overall, cladding applications are a cost-effective solution for enhancing the performance and longevity of shell and tube heat exchangers in various industrial applications.

About the author

About the author

Baher Elsheikh, Lead Mechanical engineer in SABIC, has 20 years of experience in oil and gas and petrochemical industry, particularly in the engineering and integrity management of pressure equipment. Baher is an approved ASME instructor.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in March 2024. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About the author

About the author