Virginia Tech data centre. Courtesy of Christopher Bowns via Wikimedia Commons.

Over the last couple of years, we have seen a steady increase in data centres, which are used to store data and facilitate telecommunications, among other needs. These centres generate a wealth of heat, and heat exchangers assist with both cooling and valuable heat recovery.

By Alexandra Kist, Heat Exchanger World

To find out more about the heat exchanger-focused perspective on the matter, Heat Exchanger World spoke with Anna Blomborg, Industry Manager Data Centres at Alfa Laval.

“This industry has a big sustainability challenge,” she states. Anna finds that, up until now, this industry has focused largely on green power but as much as 40% of that power is used for cooling the servers; now, the focus is moving more and more towards sustainable cooling solutions. “We specialise in data centre cooling solutions. What we often see is that in this industry, the focus lies with security and uptime. The general philosophy seems to be that the bigger the design, the more security it will offer. For instance, someone might need a heat exchanger for 500 m3 per hour, but will then buy one that can do 1000 m3 per hour, because that sounds like a safe option. In reality, the total opposite may be true,” Anna explains.

“A heat exchanger will work best when running at the designed conditions, and when designed properly. The real challenge lies there. Technology providers should be involved early in this design phase, so they can help out with coming up with the optimal design. So many heat exchangers in the world are not running as they should, and that’s an energy efficiency waste.”

Data centre boom

In recent years, there has been a rapid growth and expansion of data centre infrastructure. A data centre is a large facility used to house computer systems and related components, such as telecommunications and storage systems.

The boom in data centres can be attributed to several factors, including the exponential growth of data being generated and stored by individuals and organisations, the increasing demand for cloud computing and big data analytics, and the rise of Internet of Things (IoT) devices. The need for data centres has become critical for many companies as they require high-speed, reliable connectivity and massive storage capabilities to manage the growing volumes of data. This has led to significant investment in building and expanding data centres globally.

Moreover, the COVID-19 pandemic has further accelerated the data centre boom, with more people working remotely and using cloud-based services for their work and personal needs. Overall, the data centre boom has created new opportunities for businesses and investors in the technology sector, while also contributing to the growth of the digital economy.

Cooling data centres

Data centres need to be cooled to prevent overheating of the electronic equipment housed within them. Electronic equipment generates heat as it operates, and this heat must be removed to prevent damage to the equipment. Overheating can cause a variety of problems, including:

- Reduced performance: Electronic equipment may slow down or even shut down when it gets too hot, reducing the overall performance of the data centre.

- Increased energy consumption: As electronic equipment gets hotter, it requires more energy to operate, which can increase energy consumption and costs.

- Equipment failure: Overheating can cause electronic components to fail, which can be costly to replace and can cause downtime for the data centre.

- Fire hazard: If electronic equipment gets too hot, it can pose a fire hazard.

Cooling systems are used in data centres to remove the heat generated by electronic equipment, maintaining a safe operating temperature, and preventing these problems. Different types of cooling systems may be used, including air-cooled and liquid-cooled systems, but the goal is always the same: to keep the temperature within the data centre at a safe and consistent level to ensure reliable and efficient operation of the equipment.

A hot issue

Data centres generate a lot of heat due to the high density of computer equipment and their continuous operation. Cooling these facilities presents several challenges, including:

- Energy consumption: Cooling can account for a significant portion of a data centre’s energy usage. This leads to increased operational costs and environmental impact.

- Heat distribution: Data centres have hot spots where heat is generated more intensely. Proper heat distribution is necessary to ensure that all equipment is cooled effectively.

- Airflow management: Efficient airflow management is essential for proper cooling. Blockages, such as cables, can restrict airflow and lead to hot spots.

- Humidity control: Maintaining the proper humidity level is critical to prevent equipment damage and ensure efficient cooling.

- Cooling system failure: If the cooling system fails, the temperature can quickly rise to levels that can damage equipment.

- Scale: As data centres become larger and more powerful, cooling requirements become more challenging to meet.

- Location: Data centres located in areas with high temperatures and humidity require more cooling, which can increase energy consumption and operational costs.

Heat exchangers in data centres

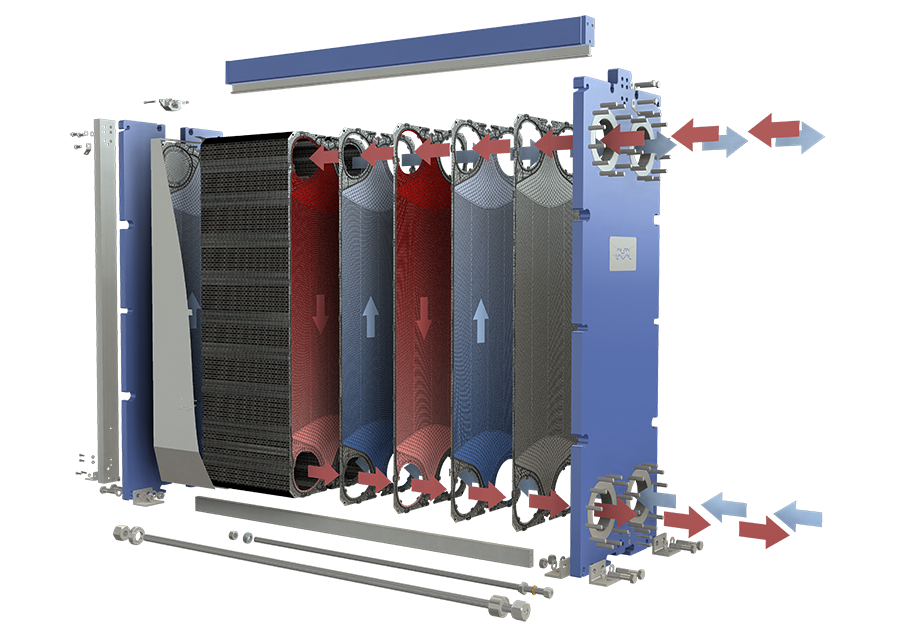

Heat exchangers are an important component in the cooling systems used in data centres. These systems are designed to remove the heat generated by the servers and other electronic equipment housed in the data centre, to prevent overheating and potential equipment failure. Heat exchangers are typically used in two types of cooling systems for data centres: air-cooled systems and liquid-cooled systems.

In air-cooled systems, heat exchangers are used to transfer the heat from the data centre to the outside air. This is typically accomplished using air-to-air heat exchangers, which use fans to move air over a heat exchanger, which transfers the heat to the outside air. Alternatively, some data centres may use a liquid-to-air heat exchanger, which uses a liquid coolant to absorb the heat from the data centre, which is then transferred to the outside air using an air-cooled heat exchanger.

In liquid-cooled systems, heat exchangers are used to transfer the heat from the data centre to a liquid coolant, which is then circulated outside of the data centre to dissipate the heat. This is typically accomplished using liquid-to-liquid heat exchangers, which transfer the heat from the data centre to the liquid coolant, which is then circulated to a heat exchanger located outside of the data centre. The heat is then transferred from the coolant to the outside air or to a cooling tower, which dissipates the heat into the environment.

“My general message to this industry is to always demand more of your equipment, suppliers, and of your heat exchangers.” – Anna Blomborg, Alfa Laval

Partnering up

One of the most important ways to optimise the cooling process is to include the heat exchanger manufacturer from the very beginning, Anna says. “We can help customers get everything just right from the start. We can help the data centre to optimise the process and we can challenge the way they cool their facilities. For example, if we were to see that the recorded temperatures look strange, we can take a look at the bigger picture. Maybe those temperatures were recorded on the two hottest days in the year in Arizona. If so, it would not make sense to design the whole cooling system around two days out of the entire year.”

Not only can the manufacturer make a difference in determining the crucial stats and acting upon them, but they can also be of great help regarding sustainability. “We can make sure that we build in a sustainable performance throughout their lifecycle. Should the data centre have pollution issues onsite, then we can come in with additional technology that can give early warnings when the heat exchangers need to be cleaned and maintained.” “The general mindset is focused on the here and now, but our heat exchangers are built to last for 20 to 30 years. We want to make sure they are up to standard throughout their entire lifecycle,” Anna explains.

“It is important for us to be involved early in the process. We have a lot of knowledge about cooling systems in general that we can apply. We can make sure there’s a sound plan in place from the very start to make sure the product and the system will keep running sustainably throughout the lifecycle.” Of course, heat exchanger manufacturers are not always immediately involved. The bigger clients, who are mostly based in the US, are increasingly reaching out to them. Smaller contractors and installation companies, however, have much to gain. They often go for an initially cheaper method, which is to create a solution with different bits and pieces, instead of opting for an extensive cooling system to be installed from the very start. “They think buying a component off the shelf is going to work,” Anna explains. “The challenge for this industry is that if they want to build truly sustainable data centres, they need to have the determination and stamina to cover the whole chain.”

Reusing the excess heat

“It’s also fantastic to see that the world is starting to look at data centres as heat plants,” Anna says. “We could heat up so much of the world with excess heat; heat that is being wasted. Data centres have a huge potential to be heat plants and give away heat to surrounding users.” Here, heat exchangers take care of the waste heat and send it off to the location that needs heating up. This could be a district heating network, a local greenhouse, or an office building, for instance. “In Norway, they are heating fish farms. There are so many opportunities. When you reuse the heat, there is less of a need for cooling. It is one of the biggest opportunities that data centres could utilise.”

Demand more

For heat exchanger manufacturers, it’s important to keep on innovating and always strive to do better. One of Anna’s key philosophies is to demand more. “At Alfa Laval, we keep tweaking. We press thinner and thinner plates to maximise the heat transfer. It’s a matter of tens of millimetres, and it makes a difference. My general message to this industry is to always demand more of your equipment, suppliers, and of your heat exchangers.”

Heat exchangers are underutilised, she says. “They’re being designed with too wide tolerances. If (retroactively) added to a data centre, they will work, but they can do so much more.” She encourages manufacturers to scrutinise every angle and millimetre and to always strive for improvement. The beauty of the heat exchanger is that they come in so many different shapes and sizes. There will always be a solution to fit the customer’s needs. As part of that process, it’s also possible to adapt over time by changing some settings or a spec.

One of the things companies and customers alike should demand, according to Anna, is AHRI performance certification. AHRI is a standard requirement in the US, but not yet in Europe. Still, conforming to such a standard ensures good quality heat exchangers.

As the data centre boom continues, opportunities for heat exchanger manufacturers increase. An, unfortunately, underutilised option is to reuse waste heat for heating up other facilities, making the cooling process not only much more efficient, but also killing two birds with one stone. One thing is clear: whatever data centre companies decide to do, there is much to gain from involving heat exchanger manufacturers from the very start. Doing so may be more expensive in its initial costs, but the improved life cycle costs will definitely be worth it.

About AHRI

The Air-conditioning, Heating, and refrigeration institute (AHri) is the trade association representing international manufacturers

of heating, water heating, ventilation, air conditioning, commercial refrigeration (HvAcr), and water heating equipment. the standards they produce ensure that various types of heating, ventilation, air conditioning, refrigeration, and water heating products perform according to manufacturers’ published claims.

Products bearing the AHri certified® mark are proven to perform accurately and consistently. backed by more than 100 years of research and development, international regulators and consumers rely heavily on AHri’s industry-leading certification programme for the accurate and unbiased evaluation of equipment. the association’s comprehensive roster of free equipment performance standards and guidelines are the basis for the certification programme and are adopted or harmonised worldwide.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in April 2023. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.