The implementation of digital technologies in industrial processes is reshaping efficiency and cost management. This paper explores the case of an LNG plant in Africa that utilized a digital dashboard and systematic trials to optimize the use of cooling water chemicals, leading to significant operational and financial benefits.

By Dr. Anal Chavan, Lead Utilities Technologist, Nigeria LNG

Digital dashboard for monitoring cooling water systems

One of the liquefied natural gas (LNG) plants in Africa includes water-cooled heat exchangers (HX’s), where cooling towers play a crucial role in production performance. A collaborative effort between utilities technologists and information technologists resulted in the development of a digital dashboard. This dashboard not only showcases operational metrics like supply temperatures, basin levels, and the availability of the chemical dosing system but also highlights critical factors such as cycles of concentrations, water chemistry and microbiology (in terms of corrosion indicators, scaling indicators, deposition indicators and bio-fouling indicators), that directly impact the efficiency of the HX’s. Ultimately, this tool enabled technologists to conduct daily interventions, ensuring that cooling water chemistry and microbiology are maintained within specifications for over 90% of the time.

Laboratory trials for chemical dosing optimization

Cooling water chemistry consists of corrosion inhibitors, scaling inhibitors, oxidizing biocides and non-oxidizing biocides (NOB’s) to control corrosion, scaling and bio-fouling in cooling water circuits including HX’s. It was observed that consumption of NOBs at this plant was nearly four times higher compared to similar plants globally. However, sudden reduction in NOB’s poses a risk of bio-fouling in HX’s with the potential of microbial induced corrosion. Thus, number of mitigations were put in-place. Firstly, a 100-day pilot trial was initiated in a laboratory setting, simulating field conditions (in terms of temperature, aerobic conditions, compensation for evaporation losses, slip stream filtration and blow-down). Secondly, an additional method in terms of ATP test kit was introduced to measure the bacterial count/cleanliness of the system, which measures the ATP in 10 seconds.

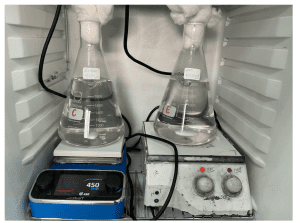

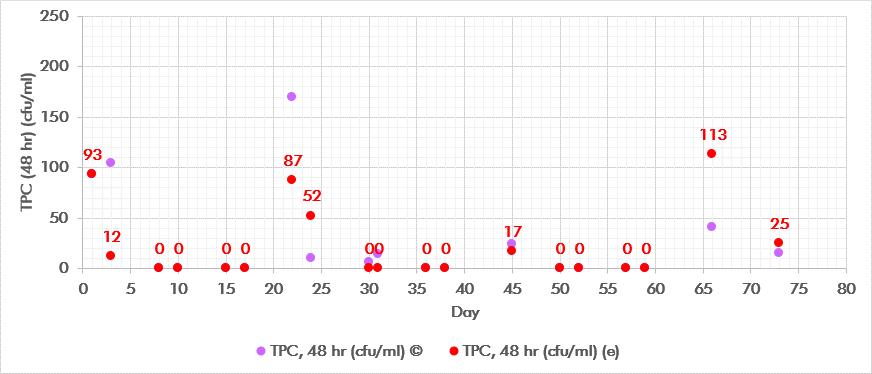

As this ATP test was not a standard test, a limit for this parameter was defined in-house based on Manufacturer’s recommendation. Thirdly, this digital dashboard was utilized for closed monitoring. In the laboratory, the trials consisted of two sets: one with normal NOB dosing (Control) and another with reduced NOB dosing (Experimental) (Fig. 1). After 80 days of trial, it was found that there was no significant differences between the control and experimental sets in terms of pH and conductivity (which impact HX integrity), Total Suspended Solids (TSS) (a deposition indicator), and Total Planktonic Count (TPC) (a bio-fouling indicator). All parameters remained within specifications. Most important parameter in terms of TPC was found well within the specifications (<104 cfu/ml) (Fig.2).

Field trials and cost savings

Building upon the success of the laboratory pilot trials, field trials were subsequently conducted and proved to be successful. Later, when heat exchangers were opened during the plant shut-down, they were found in good condition/reduced bio-fouling. This suggests that continuous monitoring was crucial, and decreasing the use of chemicals did not negatively affect the fouling of a heat exchanger (HX). Overall, this approach (digitalization followed by optimization) led to a 33% reduction in chemical consumption and an annual operational cost reduction of $200,000.

Conclusion

The use of digital dashboards and laboratory trials at the LNG plant highlights the potential of combining digital tools with traditional industrial processes. This initiative not only optimized chemical usage but also ensured consistent operational performance and significant cost savings. Such advancements underline the importance of adopting innovative solutions for sustainability and efficiency in industrial operations.

About the author

About the author

Dr. Anal Chavan is currently working as Lead Utilities Technologist at Nigeria LNG as a Shell Secondee. She is a Process engineer professional with expertise in Utilities and Specialist in Water and Wastewater systems including Cooling water. She has >15 years of experience at reputed organizations like Siemens and Shell. She is a holder of a number of research papers in reputed journals, international conferences and patents.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in March 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About the author

About the author