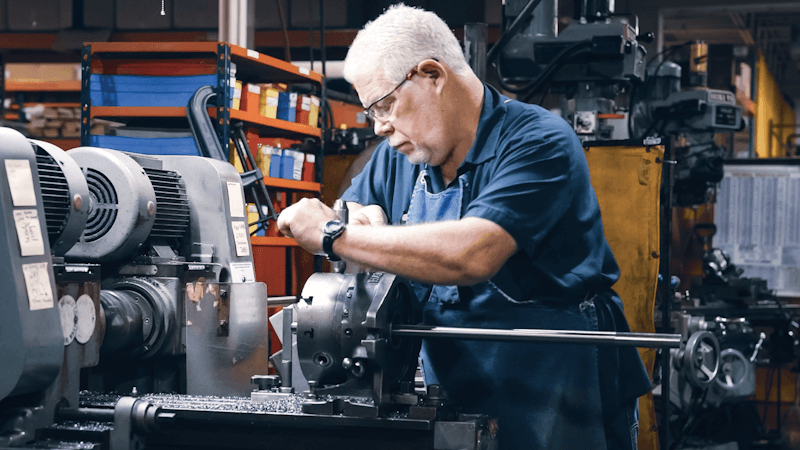

Elliott Tool Technologies designs and manufactures precision tube tools and equipment that enhance the efficiency, safety, and reliability of heat exchanger and boiler maintenance.

Elliott Tool Technologies, a well-recognized name in the heat exchanger and refinery tooling space, has entered a new era of leadership. Longtime President Mike Nemeth has stepped into the role of CEO, where he will focus on strategic direction and long-term industry trends. In parallel, Nathan Fultz, formerly part of the company’s leadership team, has been appointed President. Rather than marking a sharp break, the transition reflects continuity: an expanded leadership structure designed to balance day-to-day excellence with future-facing strategy.

By Iryna Mukha, Heat Exchanger World

Heat Exchanger World sat down with Nathan to talk about his vision for Elliott, the priorities guiding the company, and what customers can expect from this new chapter.

For readers who may not be familiar, how would you describe Elliott Tool Technologies?

“At the highest level, our mission is simple: quality specialty tools for an “I need it yesterday” world. In industries like heat exchangers and refineries, downtime costs hundreds of thousands of dollars a day. Our customers can’t afford delays. What sets Elliott apart is our ability to listen carefully to their problems and deliver solutions they can count on. We pride ourselves on providing fast, reliable tools supported by a team that stands behind them.”

“Lead time is a huge factor. Having tools ready when they’re needed is not just a nice-to-have, it’s critical. That’s why speed, quality, and dependability are at the core of how we operate.”

Many suppliers compete on price. What makes Elliott’s approach different?

“In any market, you usually see a tradeoff between price and quality. Some companies go after the cost-leader position, chasing the lowest price. That’s not our philosophy. We focus on value.”

“For us, value means a product that lasts longer, performs better, and actually saves money over

its life cycle while still being competitively priced. Customers know they’re getting more for their investment. And when you combine that with our ability to deliver quickly and consistently, it sets us apart from the competition.”

Behind those products is, of course, the team. How do you see your role in leading them forward?

“My responsibility is to ensure the whole organization is working together seamlessly. Customers don’t see the individual departments; they see the result when a tool arrives on-site. So my role is to make sure every team member, all the way from engineering to shipping, understands how their work impacts the customer experience.”

“We’re aligning around three main priorities. First, staying close to the customer. That means actively listening, sharing feedback across departments, and making sure everyone knows how their role contributes to customer satisfaction.”

“Second, innovation. Our founder invented the tube expander, and that spirit of innovation still drives us. We’re building a strong product development pipeline, not by waiting for customers to design solutions, but by listening to their challenges and creating smarter, more efficient ways to solve them.”

“Third, tightening our service promises. Customers live in that “I need it yesterday” reality. We’re focused on shortening lead times, streamlining processes, and ensuring the right products are in stock. It’s about making good on the promise that when you need Elliott, we’ll be there.”

You’ve mentioned values several times. What principles guide Elliott internally?

“It’s simple, really. We rally around four core values:

- Engage: Take the time to understand the problem before jumping to solutions, whether it’s with a colleague or a customer.

- Rally: When challenges arise, bring the right people together to solve them. Internally, that might mean supporting a teammate in need. Externally, it could mean turning the world upside down to help a customer.

- Perform: Deliver consistency. Customers should know they can rely on Elliott every time.

- Be driven: Obstacles will always exist. What matters is finding a way forward and not letting setbacks stop us.”

“These values are more than slogans, they make the foundation of our daily work”

What message do you want to send to customers and partners?

“The most important message is continuity. The same strong team remains in place, and now we’re adding more leadership capacity. Mike, in his new CEO role, will be focusing on the bigger picture: industry shifts, long-term opportunities, what’s coming three, five, even ten years from now.”

“Meanwhile, I’m focused on execution: making sure our people, processes, and products deliver on the promises we’ve made. It’s not a regime change, but rather an evolution that gives us more bandwidth to grow while keeping the core of Elliott intact.”

Looking ahead, how do you see Elliott evolving in the coming years?

“Our biggest focus is scaling without losing agility. As we grow, we want to keep the responsiveness and flexibility that customers value in a smaller company, but at a larger scale that serves more industries and geographies.”

“That means continuing to invest in innovation, ensuring our lead times remain best-in-class, and rolling out new tools that solve real problems faster. We’re highly focused on how to make those improvements visible to customers in their daily operations, whether that’s through quicker delivery, better durability, or more intuitive tool design.”

“At the end of the day, our success depends on how well we help our customers succeed. That’s the lens we use to make every decision.”

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.