The dynamic growth of the heat exchanger market poses new challenges for manufacturers as well as opens new doors and opportunities. Schoeller has anticipated the rising market needs and outlined the increasingly important role of stainless steel in heat exchangers.

By Timo Klein, Strategy & Marketing Manager – Schoeller

The market for heat exchangers is growing dynamically both globally and in Europe, especially in Germany. Forecasts predict an annual growth rate of 7 to 8 %. But where is this sharp rise in demand coming from? After all, heat exchangers have always been an important element of all major process industries around the world and are used in the oil and gas industry and in the energy, chemical, food, heating, ventilation and air conditioning (HVAC) and shipping sectors, among others.

The resurgence in demand for energy, which is still predominantly generated using fossil fuels, is making a major contribution to the current trend at a global level. On the German and European heat exchanger market, however, the drivers are different. Here, demand is being driven primarily by rising environmental standards in the supply of heat to buildings and the trend towards reducing CO2 emissions in the industrial sector. The laws passed by the German government, such as the Energy Efficiency Act (EnEfG), the Building Energy Act (GEG), are providing significant impetus. In addition, due to geopolitical changes, Europe must rely on new energy sources such as LNG, which requires additional infrastructure and represents a further sales market for heat exchangers.

Stainless steel as a key material

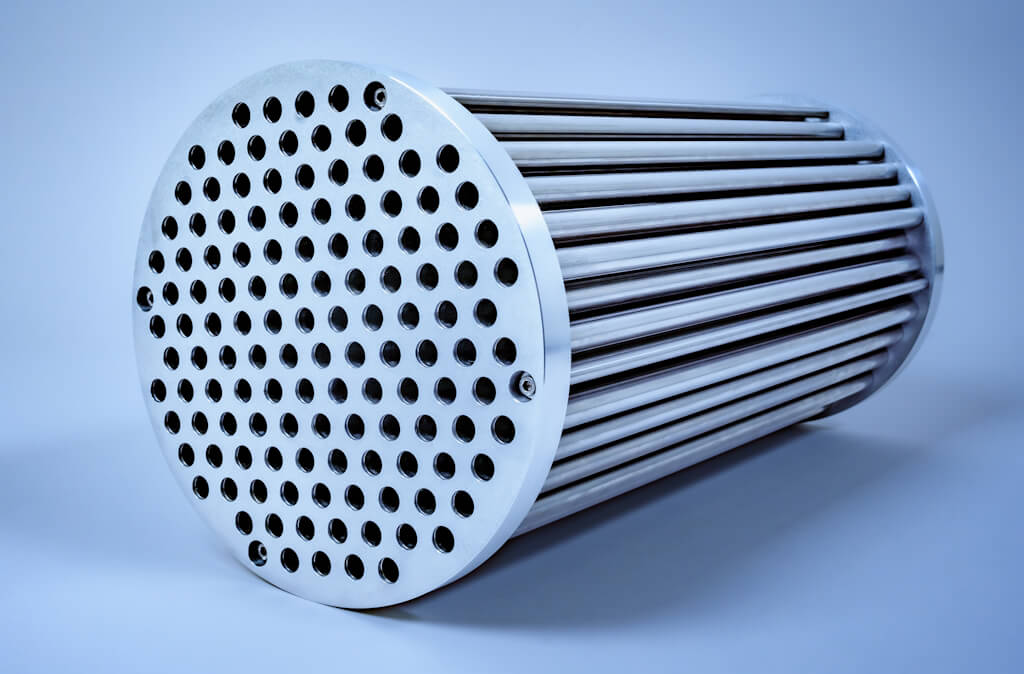

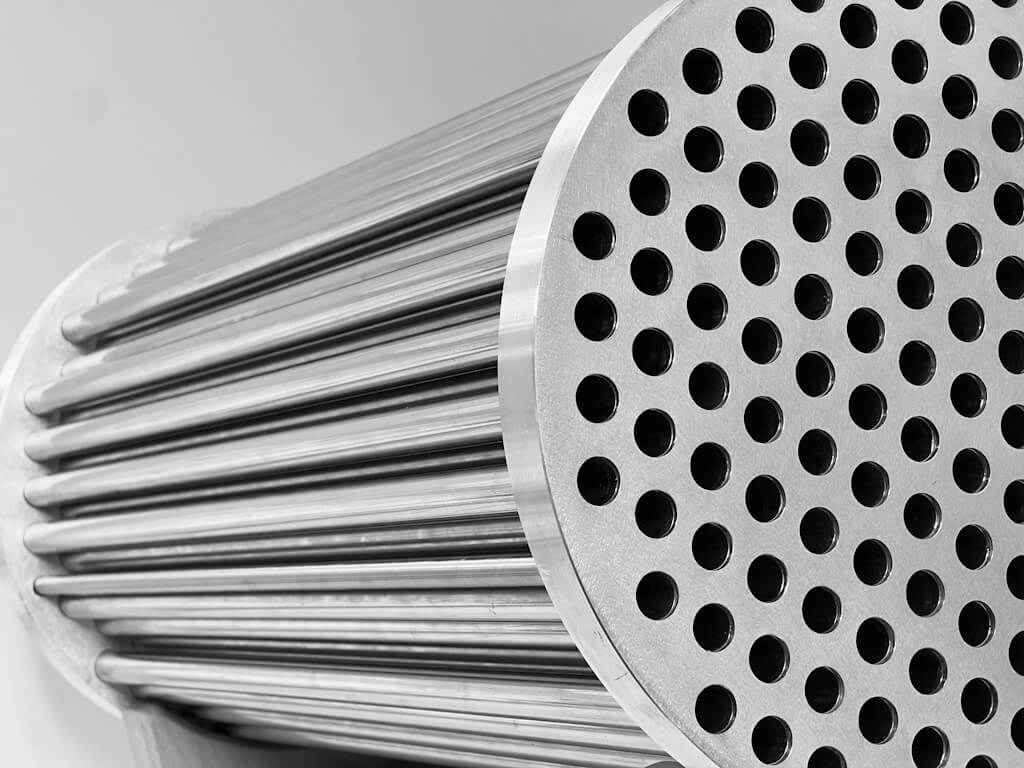

The heat exchanger market can be segmented into steel, copper, aluminium and other materials depending on application. The steel segment accounts for the largest share, as steel-based heat exchangers have high mechanical strength and excellent corrosion resistance. Stainless steel, in particular, has very good thermal conductivity and is therefore the optimal choice for heat exchangers that must withstand very high temperatures, extreme burst pressure and harsh environments. Unlike aluminium and copper, it retains its mechanical strength even at high temperatures, improving the performance of heat exchangers and helping to reduce the risk of deformation.

But that’s not all. There are other trends that are currently influencing the heat exchanger market: The requirements of industrial processes and the environment in which heat exchangers are used are constantly changing. For example, increasingly compact designs with significantly tighter material tolerances can be observed, particularly in applications in the chemical and energy industries.

All of these requirements contribute to the specific properties of stainless steel and promote market growth in this segment. Welded stainless steel tubes are increasingly being used here, replacing the higher-priced seamless stainless steel tubes more and more often. This is because premium manufacturers such as Schoeller, with their expertise and production technology such as TIG or laser welding technology, can produce welded stainless steel tubes with outstanding mechanical properties that are comparable with the properties of seamless tubes in terms of further processing as well as reliability, durability and efficiency in the construction of heat exchangers.

Rising demand drives quality and reliability

Successfully serving this market segment requires more than just the appropriate manufacturing expertise and the necessary production machinery. We are observing three other areas that are becoming increasingly important for the consumers of stainless steel tubes for heat exchangers:

- Expert material and product advice in combination with expertise in special materials and the supply of individual, customised tube lengths.

- Quality, strength, the tightest tolerances and therefore 100% guaranteed compatibility in the customer’s manufacturing process. This also includes perfect seam smoothing.

- Customer-centred, flexible logistics solutions that respond individually to the customer’s production and order situation and guarantee maximum delivery reliability despite short delivery deadlines.

This combination of material and manufacturing expertise, as well as optimised processes from order acceptance to logistics, are the necessary prerequisites for being able to benefit from the current dynamic development in the market for heat exchangers. This requires dedication to meet the highest demands, which include products with maximum corrosion resistance, functionality and process reliability as well as tight geometric tolerances and flawless surfaces

in consistently high, reproducible quality. Such a performance promise also requires regular investment in machinery and reliable delivery performance thanks to sophisticated logistics concepts.

Only with such a setup are companies able to position themselves for the upcoming trends and to be accepted as premium suppliers by the customers. Think of LNG, the ramp-up of the hydrogen economy or heat pump technology – heat exchangers play an important, if not central, role in each of these segments. And in all of these applications, customers have high requirements not only for materiality, manufacturing tolerances and corrosion resistance, but also for processes and reliability combined with a high degree of flexibility.

About the author

Timo Klein has been working at Schoeller Werk for about 4 years. He studied Business Administration at the Bonn-Rhein-Sieg University of Applied Sciences. As Strategy & Marketing Manager at Schoeller, Timo is responsible for the company’s marketing and PR/public relations as well as for the “Strategy” division and thus for Schoeller’s strategic positioning.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in February 2024. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.