Variable Speed Drives (VSDs) are emerging as one of the most effective solutions for optimizing energy use in refinery air coolers. By precisely matching fan speed to process and environmental conditions, VSDs minimize unnecessary power consumption, improve efficiency, and reduce noise. This article examines their advantages over traditional control methods and highlights the potential savings achievable through their application in ACHE systems.

By Uma Sankar Khan, Technical Professional Leader, KBR

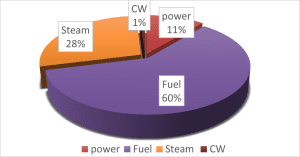

Refineries are designed to handle a wide range of crudes to have greater operational flexibility. These crudes usually differ widely in their characteristic, resulting in quite different yield patterns. As final product destination conditions are broadly outlined, equipment is specified and designed catering to various operating conditions. The Air-Cooled Heat Exchangers (ACHE) are no exceptions. ACHEs are typically designed and optimized to cater to a variety of operating conditions usually under various stringent scenarios (i.e., maximum process duty while encountering maximum ambient temperature) because of the seasonal variations in the ambient temperature during the year and the change in type of crude processed. ACHEs without proper control of airflow will supply too much cooling air most times of the year, leading to higher power consumption. ACHEs are extensively employed in refineries to reduce the temperature of process streams to about 60-65 0C, which is then followed by a water cooler to cool the process streams to their respective desired temperature. ACHEs typically account for about 10-15% of the total power required in primary distillation units, which translates to approximately 2-3% of the total energy required in these units.

As air coolers are predominantly operated at lower heat duty and ambient temperature than their design conditions, there exists extensive potential for energy saving. In this paper, energy conservation opportunities in refinery ACHEs are addressed using variable speed drives/variable frequency drives (VSD).

Regulation of air flow

A fan without a flow controller supplies too much cooling air most of the year and thus often leads to unwanted sub-cooling of the products. Furthermore, the power consumption of the fan supplying the full air volume is unnecessarily high. Reducing airflow as conditions permit can result in substantial power saving and reduced noise level, since former goes with the third power of the airflow requirement. To match the system requirements with the fan output, one of two basic approaches may be adopted. One approach is to change the system curve and the other is to change the fan performance curve. Some of the most commonly employed approaches are described below along with their advantages and disadvantages.

- By placing damper: For flow throttling, a damper is placed upstream or downstream of the fan, and the system curve is modulated to give the desired airflow rate. This mode of controlling fan capacity is energy inefficient, noisy, and may also lead to flow instabilities.

- By shut down of individual fan: This is achieved by shutting off one of the two fans in each bay. On-off fan control is simple, but it can cause problems in ACHEs such as water hammering, tube-to-header leakage, nozzle-flange leakage and so forth. Power saving depends solely on operators’ judgement, and greater operator interventions are also required in this case. Moreover, shutting off a fan causes step change leading to instabilities in the process. Due to its very nature, it does not permit savings of full potential.

- By controlling pitch of the fan: For energy-efficient control of fan capacity, it is always preferred to change the system curves. The fan’s blade angle or rotational speed may be changed to adjust the fan’s performance curve. To change the blade angle, thereby controlling the fan capacity, either manually adjustable or auto-variable fans are adopted. However, energy conservation for manually adjustable fans depends solely on the efficiency of the operator; for manual adjustment of the pitch, a temporary shutdown of the fan may be required. Therefore, auto-variable fans are preferred over manually adjustable fans. These fans automatically adjust pitch in response to a preset operating variable (mainly, product outlet temperature). The most frequent complaints about variable pitch involve its reliability. Many instances of the fan blade getting stuck due to various reasons have been reported. Furthermore, with variable pitch fans, the motors run with the same speed but at lower load, adversely affecting its efficiency.

- By changing speed of the fan: Changing the fan’s rotational speed also changes the fan’s characteristics and reduces airflow with substantial power savings and reduction in noise level. Variable voltage DC motors, using transformers and rectifiers may be used for controlling the fan’s rotational speed. However, such DC motors require frequent maintenance, and their part load efficiency is very poor. By changing the number of poles of the fan’s induction motor rotational speed, operating with pole changing motors may be controlled with only a few discrete values and may cause system control problems. Therefore, full potential of power saving is not realized in actual practice by the above measures.

Inherent characteristics of fan-motor system

The energy-saving potential of different air flow controls mechanisms, discussed above, are limited due to their inherent characteristics, briefly discussed below.

- Fan efficiency: Efficiency for a fan of particular design is a function of the fan’s geometry (such as diameter, hub diameter and tip seal) and airflow (i.e., pitch). For auto-variable fans, the blade angle at clevis is changed to adjust the pitch. At or near full load, a fan’s efficiency is changed very little. Reducing the velocity by reducing the blade angle results in a change in efficiency because velocity is reduced while the RPM remains constant.

-

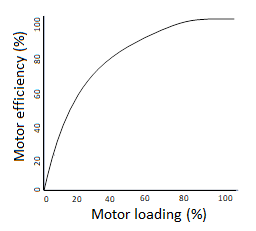

Figure 2. Variation of electric motor efficiency under different loading for constant speed-motors. Motor efficiency: Three-phase induction motors are used mainly to drive the fans. As the air flow requirement decreases due to reduction in ambient temperature, the motor operates

at part-load conditions. Efficiency and power-factor of an induction change with the loading of an induction motor. Until 50% loading, variation in motor efficiency and power factor is negligible. However, the efficiency and the power factors are significantly lower than their full load values for induction motors operating with 40% of the design load or less. This results in lower efficiency for fixed blade and auto-variable fan-motor systems. Typical electrical motor efficiency under different load condition is shown in Figure 2. It is evident from the above that the total efficiency of the motor and fan system decreases significantly at lower than design load.

VSDs as energy-saving devices

VSDs provide the best way to control air flow, in terms of energy efficiency and operational flexibility. Variable frequency drive technology has been underutilized and its potential not yet realized to convert power in refineries. Optimum system performance can be achieved if the fan, the VSD-motor unit, and the accessories are selected with adequate precaution. Use of VSD allows power savings on account of the following:

- Change in process duty due to change in throughput and/or type of crude being processed

- Seasonal and daily variations in ambient temperature

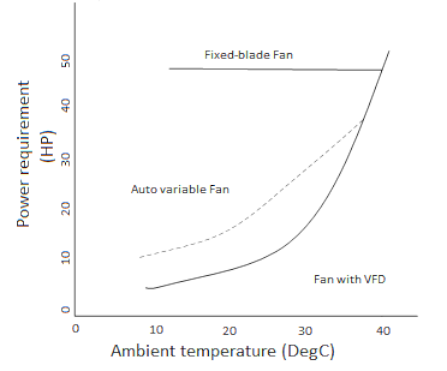

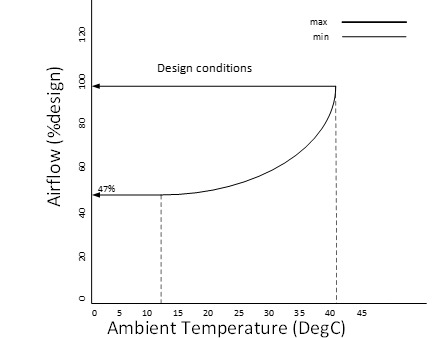

The power saving potential is fully exploited by maintaining motor efficiency at reduced load. Most of the saving will occur when the variation in type of crude and seasonal temperature variation are accounted for. As mentioned above, the ACHEs are typically designed for maximum ambient temperature encountered in the geographical area. Even in the middle of the summer, ambient temperature varies significantly between day and night. Hence, power saving is possible daily. The typical power requirement for fixed blade fans, auto-variable pitch fans, and fans with VSD at different ambient temperatures is shown in Figure 3A.

Case study

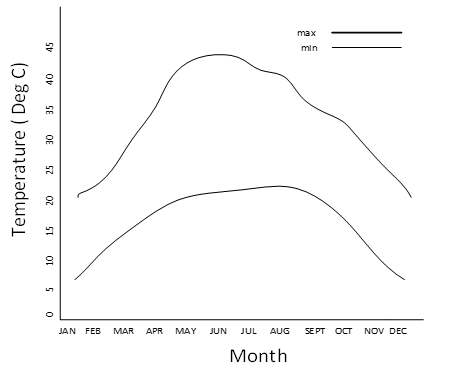

An air temperature of 39 °C is considered where ACHEs are followed by water coolers. When the ambient temperatures rise to 45 °C, the ACHEs will underperform. But downstream water cooler is designed to take care of additional duty under such an eventuality.

Approach: Based on the site average climatological data presented in Figures 3A and 3B, the whole year is divided into four temperature zones by combining those months where the maximum and minimum temperatures are similar. In addition to seasonal temperature changes, daily temperature variation also takes place and is accounted for.

Evaluation:

- Airflow requirement: Required airflow and static pressure are obtained from different ambient temperatures from detailed simulation of the ACHE’s design using actual design software. Typical results are shown in Figure 4.

- Power requirement: For fans with fixed blade angle air flow, rotational velocity of the fans is not changed to control the air flow, but the air flow is throttled to reduce it. This is the most energy-inefficient operation of the fan motor system and practically results in no savings.

For auto-variable fans, the blade angle at clevis is changed to match the required airflow and static pressure for different ambient conditions, keeping the original speed of the fan same. Performance equation of motor fans have been used to calculate the power requirement by an auto-variable fan operating under different ambient conditions.

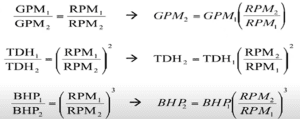

The rpm of a fan operating with VSD is changed to match the required airflow and static pressure with variable ambient temperature, keeping the original blade angle at clevis of the fan the same. Reducing velocity using a variable frequency drive does not result in a change in efficiency since the velocity and the rotational speed are reduced by the same proportions. The pitch, therefore, remains constant.

Saving in power due to change in rpm is estimated using the characteristic and performance equations of Moore Fan.

Energy savings potential:

Refineries can reduce fan speed by 20-30% using VSDs, leading to 25-35% energy reduction.

- Example: Speed control vs on/off cycling; Demand = 50%

Power2 = (1/2) Power1

Motor Configuration:

- Typically, 50% of fan motors are manual on/off and 50% are variable speed.

- If needed, 100% of motors can be variable speed for enhanced efficiency.

Conclusion

A rated capacity saving of at least 20% could be realized on account of seasonal temperature variation and duty variation owing to different processed crude. In case of units not operating normally at a rated capacity throughout the year, power saving will still work out to be higher.

The payback period for other refineries (capacity and location) may vary depending on site-specific conditions such as seasonal temperature variations and the varying types of crude being handled. In addition to energy saving as a result of reductions in speed, tremendous reduction in the ACHE’s noise level is also of great advantage.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in October 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.