The threat of a gas-less, oil-less winter is a very real concern for Finland, the country with the EU’s longest Russian border. Following the Finnish government’s decision to join NATO in recent months (a decision in itself stemming from Russia’s invasion of Ukraine) Russia has halted its supply of gas and oil, as well as fluctuating its electricity exports. As with the rest of the world, however, Finland has been preparing for a shift in energy production and these latest disruptions have only expedited research projects for more local but still reliable source and storage of power. One engineering-led company in Finland, called Polar Night Energy (PNE), has found a potential solution that is both cheap and impressively simple: Sand.

By Ellie Pritchard

One of the more complicated aspects of renewable energy production is working out what to do with the excess heat/water/power when there is a surplus; how can it be stored for long periods of time, but be ready to use when there is a lack of solar or hydro power? How can we smooth out those peaks and troughs of energy supply?

The chemical engineer Donald Sadoway (Professor Emeritus of Materials Chemistry at the Massachusetts Institute of Technology) has been quoted as saying: “If you want to make a dirt-cheap battery, you have to make it out of dirt.” Polar Night Energy seems to have taken that suggestion literally.

I spoke with the company’s CTO, Markku Ylönen, about the technology, benefits, and seemingly limitless potential of this energy storage system.

“Someone else’s dirt could be our heat storage medium.”

Simple but effective

Tommi Eronen (right). Source: BBC

Polar Night Energy was founded by Markku Ylönen (CTO) and Tommi Eronen (CEO) in 2018, but they have been working on the concept of a sand battery for 10 years. Both studied power plant engineering with a keen interest in thermal dynamics, flow dynamics, and heat transfer. The pair turned their knowledge to heat storage, discovering that the electricity market was making changes in the direction of wind and solar, producing cheap and clean energy which would need to be stored during times of low demand for later use. Seeing the limitations of water systems for energy storage, Polar Night Energy had an alternative solution: “We use really, really hot sand as the storage medium.”

The PNE sand battery is capable of providing heat at the extremely high temperatures required by the process industries, unlike water storage systems. With a maximum temperature of 100 degrees, a water storage unit would need to be pressurised to reach higher temperatures, but this is not an option in large-scale applications.

The company’s website explains the innovative system:

“We convert electricity to heat, and store it for later use. We use sand as the storage medium, which leads to safe operation and a natural balance in the storage cycle. Additionally, sand is a cheap and abundant material, which can be heated up to 1000 °C and even higher.”

The high degree of insulation between the storage and environment ensures a long storing period, up to months, with minimal heat losses.

Current applications

One of the sand battery’s initial case applications was in the Finnish city of Kankaanpää, where PNE installed the system for energy provider, Vatajankoski. The storage provides 100 kW heating power and 8 MWh capacity.

Vatajankoski uses the heat provided by the sand battery to prime the waste heat recovered from its data servers which are intended for high performance computing before feeding the waste heat into the district heating network.

Depending on the season, the temperature of the 60-degree waste heat from the servers must be raised to 75–100 degrees before it is fed into the district heating network.

Pekka Passi, Managing Director of Vatajankoski says of the project: “We are actively developing our energy production portfolio towards a 100% sustainable and emission-free future. Polar Night Energy provides a perfect solution for our needs.”

There have been many reports claiming that the Polar Night Energy sand battery system could be installed below ground, an attractive concept for very large-scale applications, but Markku is keen to clarify that although possible, underground energy storage would pose another challenge. “For the Kankaanpää case, the sand is stored in a silo above ground because it was relatively easy to build. When you start looking at below-ground options, you have to tackle water leakage. A small amount of water in the sand storage would obviously just evaporate, whilst taking up energy from the unit. But if you have a large amount of water, it will compromise the whole system.”

He explains that the heat transfer system could easily be transferred to an underground space, but that water protection would make the purposely simple concept more complicated. However, PNE is already exploring future possibilities in this regard.

“Certain spaces would be ideal, such as quarries, as they are already dry. The storage would then be hidden and you’d be saving the cost of the steel housing,” Markku confirms. “Water presents a big issue, but underground storage is definitely something we are looking into. It would especially lend itself to these large-scale projects that we’d like to focus more on.”

Why sand?

This current sand-based solution is around three times more efficient than water, and can store far more energy than a water tank of a similar size. Sand is therefore a space-saving and versatile approach to energy storage, and can be used in a vast arrange of industrial applications.

“The heat storage is not very sensitive to sand grain size,” the company states. “We prefer high density, low-cost materials that are not from scarce sources. Someone else’s dirt could be our heat storage medium. We prefer to use materials that are not suitable for the construction industry.”

Associated cost comes less from the storage medium, sand, but rather from the pipes and related equipment. However, PNE believes that the global reliance on combustion as an energy production method has a limited life expectancy ahead of it. “More than 90% of energy generated in industry to heat our buildings is made by burning something: wood chips, natural gas, oil, peat,” says Markku. “We need to replace almost all of it if we want to have any chance of meeting our climate goals.”

The company believes that, in the future, the cost of combustion will rise significantly meaning that burning will no longer be such a financially attractive option – the lower relative cost of renewable energy production and storage will be far more popular.

How does the sand battery work?

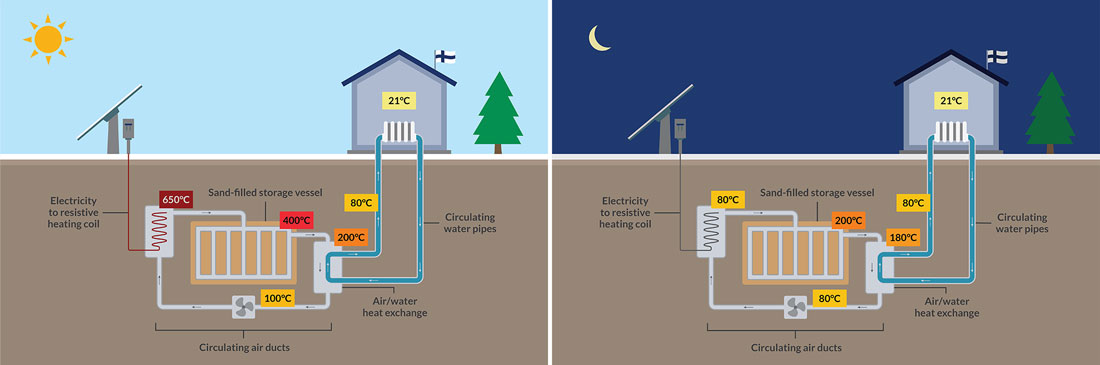

The heat storage system is made up of an insulated steel silo, filled with sand and heat transfer pipes. The only other equipment required consists of automation components, valves, a fan, and a heat exchanger or steam generator.

“We have the large heat exchanger buried in the sand, which is our own technology. And then outside of the storage is a quite conventional heat exchanger; in the Kankaanpää case, it is an air-to-water heat exchanger,” says Markku. “We have this closed air loop, which is our patented technology, so we heat air using electric resistors when discharging the storage and that hot air passes to the air-to-water heat exchanger.” Depending on the needs of the application, the sand

can reach temperatures between 600 and 1000 degrees Celsius. Markku explains that “in practice, the maximum temperature of a sand-based heat storage is not limited by the properties of the storage medium, but by the heat resistance of the materials used in the construction and control of the storage.” Although the company remains close-lipped on the exact details of its heat transfer system, Markku confirms that stainless steel is used.

Scaling up

But the Kankaanpää unit is still only the beginning, as it sits at the lower range of PNE’s system capabilities.

“The Kankaanpää system includes boosting up waste heat from a data centre, so this means that a small storage can work if there is an additional business model included,” says Markku. “But we really want to focus on scaling up much larger than this. The larger the storage, the better the ratio; there is more capacity and the relative losses are lower.” And the system is certainly scalable. PNE’s proprietary heat exchanger buried amongst the sand is as easy to arrange for large-scale as it is for small-scale, and the control system remains simple even in a unit 100 times larger. The project has gained attention and interest from around the world, and PNE is now in negotiations with customers in the process industry and energy sectors.

“Finland was a great place for us to start, as it relies a lot on district heating. But we want to move into bigger industrial applications; heat generation for industrial processes is responsible for up to 20% of the global CO2 emissions – so there is a lot of work to do in this sector. And we want to help.”

In terms of limitations, the sand battery has very few. A modular system capable of scaling up without a foreseeable limit offers an ideal solution to one of renewable energy’s biggest challenges. However, Markku admits that the system does require short distances between the storage unit and the customer. “Transferring heat over long distances, either through hot air or water, is not efficient. So we’d need to practically limit the storage site to 10 GW hours of capacity because going larger than that, the benefits of scaling up start to diminish,” he says.

Data and simulations

To aid in maximising the efficiency of the design, PNE used COMSOL Multiphysics® software to create dynamic models of the sand battery system. Through the Comsol system, they could also access a wide database of real-world heat transfer data.

Markku explains that they opted to create time dependent models because of the importance of understanding the dynamic nature of the heat transfer. The team use the platform as a design tool for the heat transfer side, but not the mechanical structure. It gave them the ability to model the entire system on selected timeframes. “For example, we could look at hourly based data for a full year, then we’d get a fairly good estimate for what we can deliver each hour of the year with our system in practice,” he says. “The demo plant in Tampere, which we set up before the first commercial system in Kankaanpää, was used to validate our models to compare real life data and data from the programme.”

The PNE team used the programme to confirm whether or not certain designs were capable of storing heat for very long periods of time, eventually coming to the conclusion of using evenly distributed hot air ducts throughout the sand storage unit. This software enables engineers to build predictive models rather than full-size prototypes, meaning they can test multiple ideas before committing to the most efficient. Having real-world data on hand gives PNE the assurance that its systems are successful and meaningful contributions to a global dilemma.

Key figures

Temperatures: 600 – 1000 °C (depending on the design)

Nominal power: Up to 100 mW

Capacity: Up to 20 gWh

Efficiency: Up to 90%

Storing cycle: Hours to months

Lifespan: Tens of years

Investment cost: <10 euro/kWh of storage capacity

Safety: 0 poisonous or hazardous materials, minimal emissions

Running costs: Minimal, no consumables, fully automised

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in September 2022. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.