Regardless of the application, the main challenge in heat exchanger design is to achieve the optimal balance between layout/footprint, costs, weight and, of course, the thermal efficiency and longevity. The performance and lifetime of shell and tube heat exchangers depend heavily on the choice of material and tube design.

By Olivier Favrat, Innovation and Development Manager, NEOTISS

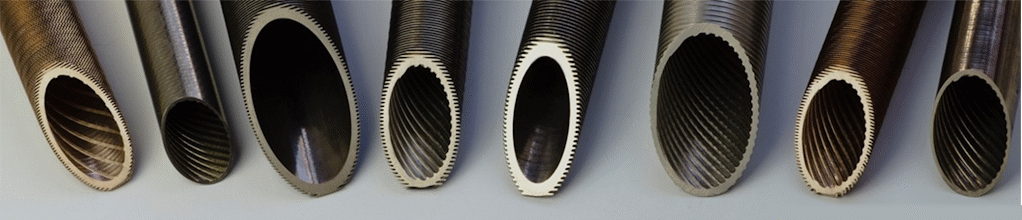

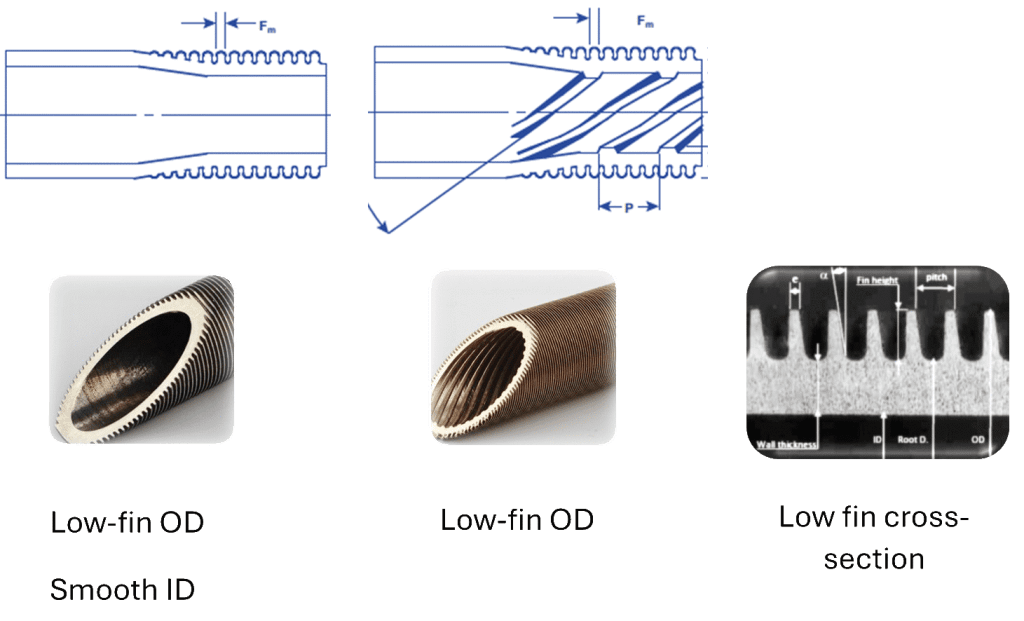

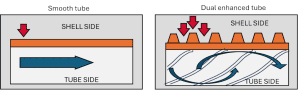

To enhance and optimize heat transfer efficiency in heat exchanger tubes, various innovative solutions have been developed. These include the application of external low fins, internal ribs (commonly referred to as microfins), or a combination of both. These enhancements are adaptable to a wide range of materials, such as titanium, stainless steel, duplex or nickel alloys, copper, and aluminium, ensuring versatility in addressing diverse industrial requirements.

Enhanced tubes benefits and expected performances

Enhanced tubes can be utilized for both new heat exchanger design and retrofitting existing heat exchanger. It enables to increase heat duty for a limited heat exchanger size, to decrease the layout of a heat exchanger by decreasing their size or by limiting the number of heat exchanger in case of multiple heat exchangers or, to lower the total heat exchanger cost (tube and assembly costs).

For sensible heat transfer (no phase change) heat duty transferred though the tube surface can be written as:

Q = U . A . ∆T [1]

Where Q is the exchanged heat duty (W),

U is the heat transfer coefficient (W . m-2 . K-1),

A is the exchange area (m²),

∆T is the temperature difference between hot and cold fluids (K).

Surface modifications can be performed to increase the heat duty calculated from the equation [1].

Low fins are created by a cold deformation of the outside surface of the tube. One of the consequences is that it implies an increase of the outside tube area (A in equation [1]).

Internal ribs are created by a cold deformation of the inside surface of the tube. It generates local flow turbulences which increases heat transfer coefficient (U), in equation [1], with minimal impact on pressure drop.

Figure 1 shows the design of enhanced tubes whereas Figure 2 illustrates the performances modifications. Low fins and internal ribs modify the surface area, pressure drop and heat transfer coefficient by a factor that depends on fin/rib density and shape, on tube diameter and thickness, on the fluid properties, and on the process conditions. Typical range of coefficients are summarized in Table 1.

Selection of tubes and the related impact on heat exchanger performances can be assessed using a thermal process design and simulation software such as HTRI that includes Neotiss tubes references and performances, under its brand HPT (High Performance Tubes).

Even in the case where the cost of enhanced tubes is higher than the cost of smooth tubes, the total price is always balanced by the fact that less material is necessary (decrease of required tube length and/or number of tubes), shell cost decreases because the size is reduced, and assembly costs also decrease when less tubes are necessary.

Significant gain can also be realized by debottlenecking cases where heat duty is limited in an existing shell size.

Also, Neotiss brings its heat transfer expertise to propose the most suited tubes for the customer defined application and specifications.

Production of welded enhanced tubes

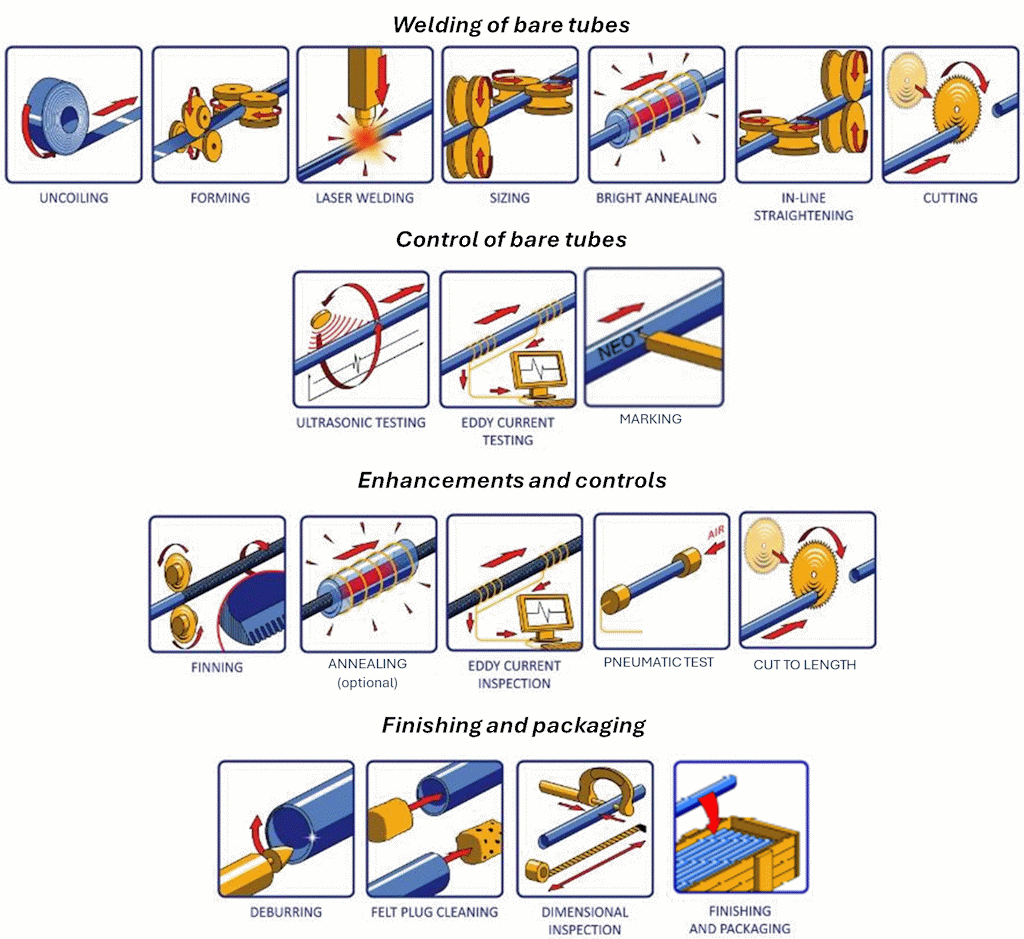

Example of Neotiss full integrated process for producing such enhanced tubes is illustrated in Figure 3.

The main steps of the fully integrated manufacturing process are detailed on Figure 3. A series of forming rollers forms the tube which is welded by TIG or laser. Tubes are then annealed and cut. All tubes are 100% submitted to Non-Destructive Tests (NDT) and marked for traceability. Then, low fins and/or internal ribs enhancement are performed by cold forming, so without adding nor removing material. Low fins are created by stacks of discs that are pressed against the external tube surface. Internal ribs are created by a mandrel with spiral grooves that acts on the inner surface of the tube. Heat treatment following the cold forming could be performed to remove the stress induced, for specific applications. A new set of NDT is performed before cutting to final length. Tubes are then deburred, cleaned and inspected before a careful packaging.

This process can be subjected to slight variations (bending, additional tests as well as hydraulic test…) depending on customer requests.

Destructive tests, not displayed here, are also realized according to international standards and customers’ specification.

| Smooth tube | External low fin | Internal ribs | |

| Surface area | 1 | 2 to 3 | 1,25 |

| Pressure drop | 1 | 1,1 | 1,4 to 1,8 |

| Heat transfer improved coefficient |

1 | 1 | 1,7 to 2,5 |

Table 1 : Impact of enhancements on surface area, pressure drop and heat transfer coefficient

Highlight on NDT

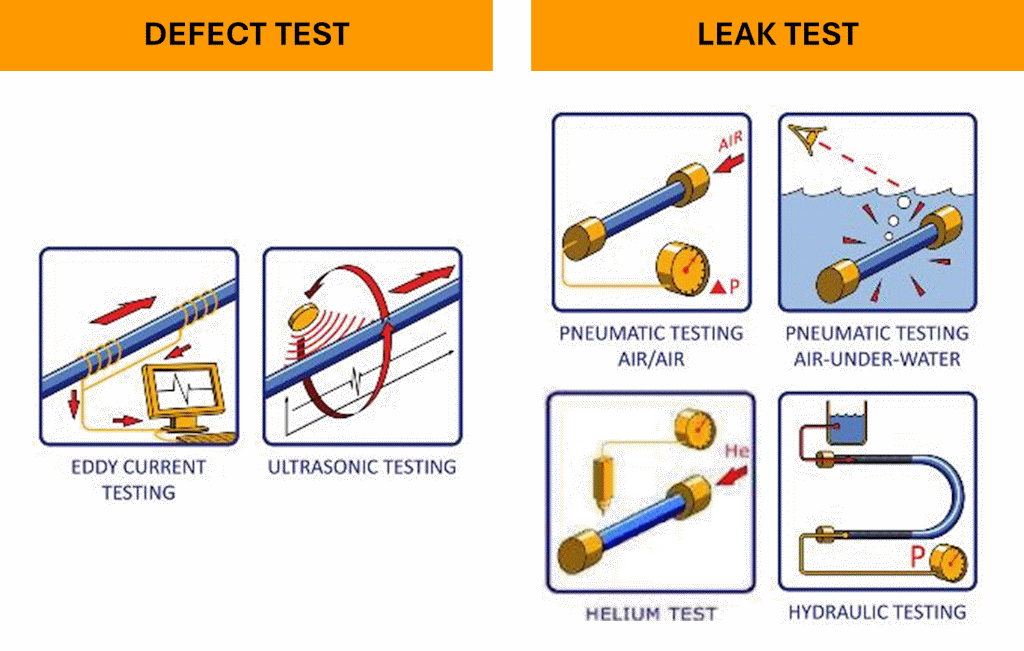

The Non-Destructive Tests belong to Neotiss’ DNA, as they guarantee the tubes quality and integrity These tests are detailed on Figure 4.

Eddy current and Ultrasonic testing on bare tubes enable to detect defects such as pores, inclusions, holes, edges mismatches, cracks, lack of welding… whereas leak tests (air/air, air under water, helium test and hydraulic test) enable to detect weld stoppage, cracks, holes. High-pressure hydraulic testing also serves as a mechanical integrity test. Eddy current testing on finned tubes allows to detect defects on fin shape or metal inlay.

By applying the right Non-Destructive Tests, Neotiss ensures that the quality of the tubes complies with the level required.

About the author

Olivier joined Neotiss SAS in 2019 as Innovation and Development Manager.

His background in Material Science and his technical approach allow him to lead development of products and processes. He is also involved in heat transfer expertise to carefully take in account customer needs.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in March 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.