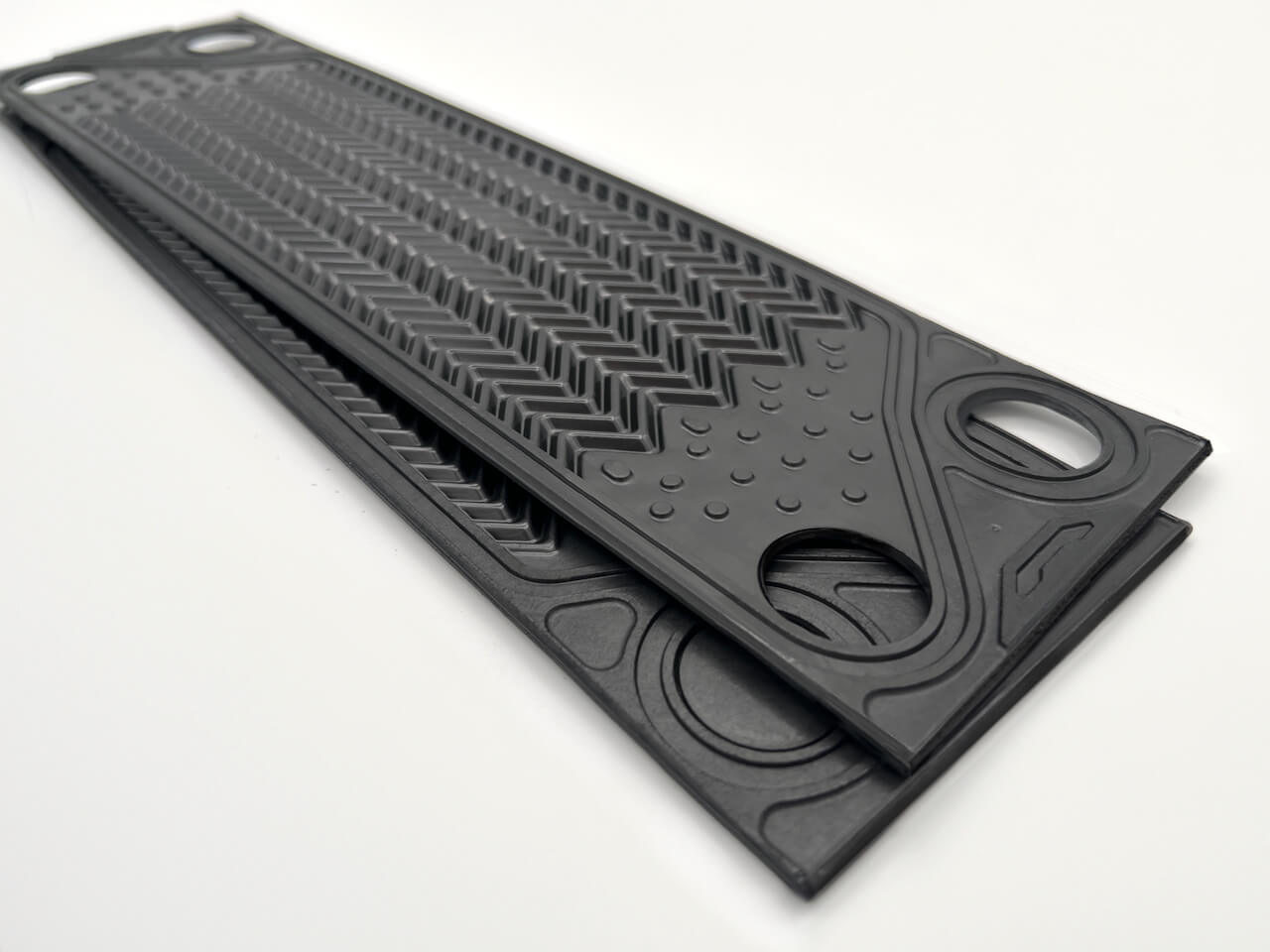

Reliefed’s forming technology producing complex geometries in one continuous step.

A patented method from Reliefed is changing the game for heat exchanger plate production – enabling rapid, cost-efficient manufacturing using composites, ceramics, and polymers instead of metal. The result: lighter, corrosion-resistant, and more sustainable thermal systems.

Text & images by Reliefed

Swedish manufacturing innovation company Reliefed has developed and patented a manufacturing method that redefines how non-metallic flow plates can be produced for heat exchangers and thermal systems. By upgrading the conventional extrusion process with inline precision forming, the company can manufacture fully structured flow plates with complex geometries in a single continuous step, reaching production speeds of seconds per plate.

This removes the design and scalability barriers that have previously limited the use of composites, ceramics, and polymers in flow plates. The result is a highly efficient production method that opens new material possibilities, reduces manufacturing costs, and supports the industry’s shift toward lower carbon, corrosion and fouling resistant solutions.

Moving beyond metal

Many heat exchanger systems continue to rely on stainless steel, titanium, or nickel-based alloys for plate production. While these materials are mechanically robust, they are often used as a safeguard rather than a precise match for the operating conditions in large part due to the limited availability of alternatives that meet both performance and production requirements. In addition they contribute to higher material costs, energy usage, and high environmental impact.

Non-metallic materials offer benefits such as improved corrosion resistance, reduced fouling, and lower weight. Until now, their use has been limited by slow and expensive manufacturing processes. For example, compression molding, injection molding or extrusion and machining of heat exchanger plates typically have a cycle time of several minutes per plate. Reliefed’s method can energy efficiently produce a fully structured plate in a matter of seconds reducing cycle times and cost of production.

A new approach to extrusion

The patented forming process developed by Reliefed, retrofits directly onto existing extrusion lines. Using custom tooling and a rotating shaping element, the method continuously forms flow channels into extrudable materials. This enables single-step production of three-dimensional plate geometries without additional machining, pressing, or secondary handling.

The process is material agnostic and has been validated for use with a range of materials; composites, technical ceramics and polymers. The company has already validated the technology for flow plates with complex flow structures in a large range of materials like for example highly filled graphite composites and various technical cerams.

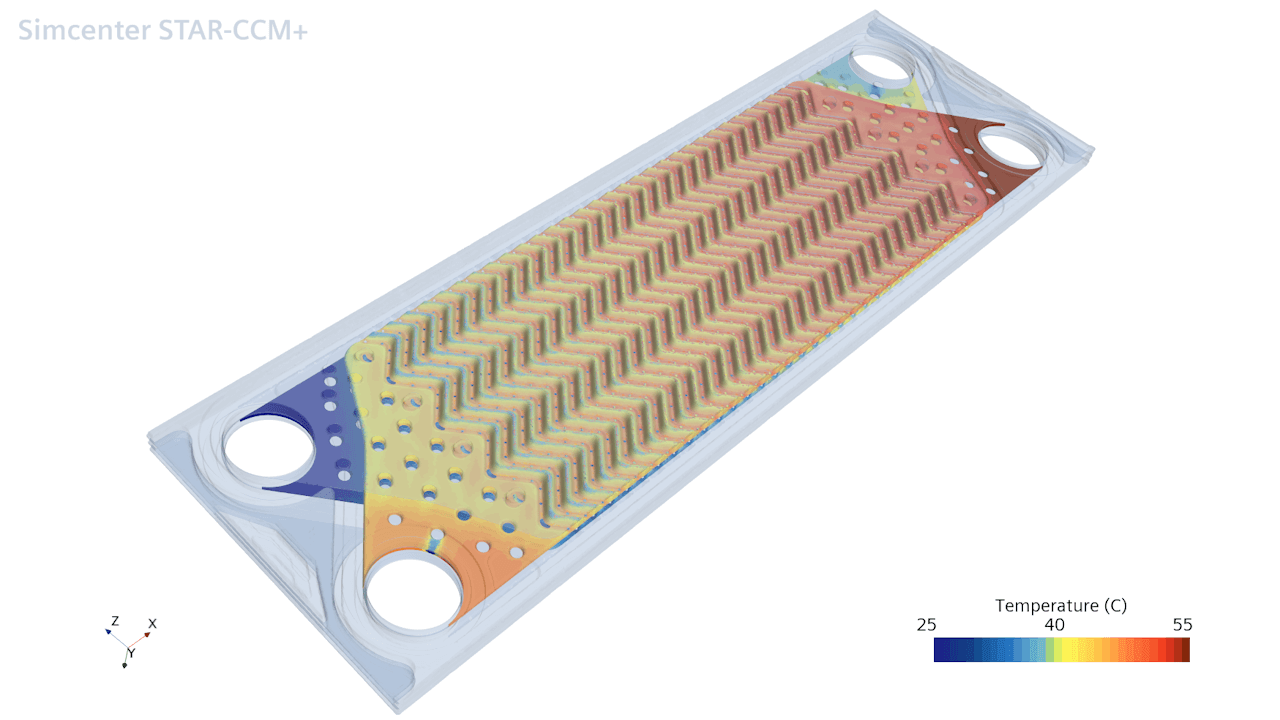

Technical performance and design freedom

One of the advantages of Reliefed’s technology is the design freedom it enables. When compared to conventional metal stamping the process supports sharper release angles and asymmetric geometries, such as different designs on each side of the plate. Unlike injection molding, the plate dimensions are not constrained by the need to fill a mold cavity from a central gate. The in-line forming approach removes these flow limitations, allowing for a wider choice of materials and greater flexibility in plate size.

A major cost-efficiency driver is the modularity of the tooling. By incorporating interchangeable or rotating elements, a single tool can produce a variety of flow patterns for the same plate size. This makes it possible to tailor designs to specific application needs without the high costs and long lead times typically associated with custom tooling. From a technical standpoint, the plate has shown strong potential to meet system requirements in both simulations and real-world testing.

Environmental considerations

Non-metallic flow plates offer a significantly lower carbon footprint compared to metal alternatives. Metals require energy-intensive extraction, melting, and forming, while polymer and composite materials can be processed with far less energy. Reliefed’s continuous forming technology further reduces environmental impact by operating at lower temperatures and using less energy per part than conventional methods like machining or injection molding.

In addition, the use of corrosion-resistant materials extends product life and reduces maintenance needs over time. This not only improves system reliability but also contributes to lower total emissions across the full lifecycle of the product

From pilot to production

Reliefed has already worked with partners in the energy and transportation sectors, including Alfa Laval, Volvo Group, and Polestar, to test and validate its plate technology for various flow plate designs. These cases span applications in hydrogen fuel cells, battery cooling, and heat recovery from aggressive gas streams.

Initial sample deliveries has already begun, with pilot capacity based in Sweden. A larger rollout is expected to follow in 2026 with internal capacity for high volume plate production serving customers’ needs to scale fast.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.