Safety shell and tube heat exchangers were developed and patented back in the 80’s by FUNKE Wärmeaustauscher Apparatebau GmbH with its registered office in Gronau/Leine as a solution for the highest plant safety standards.

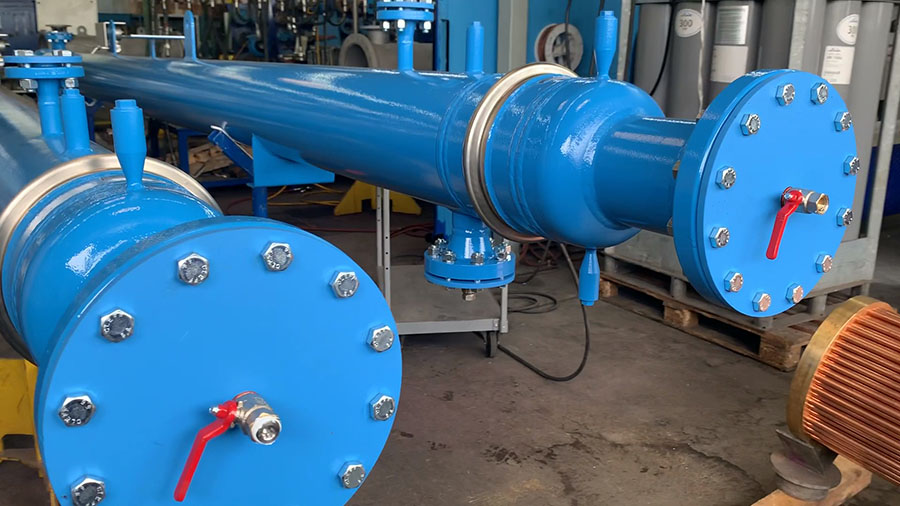

Now FUNKE Is bringing an innovative and efficient further development to the market: With the SWF-HE, double-walled tubes and a safety space with leak monitoring guarantee plant safety and so improve plant efficiency since any unplanned downtime can be avoided. Moreover, the SWF-HE saves space and may be used for high operating pressures of up to 100 bar and temperatures of up to 300 degrees Celsius.

The top priority with the development of the new SWF-HE was the combination of absolutely reliable medium separation and optimum heat transfer without the use of an additional medium in the safety space. In this technical solution, two individual tubes made of steel or stainless steel – one hidden inside the other – are used, with the inner tube of the pair having a fine pyramidal structure on the outside.

The two tubes are connected to each other metal to metal by hydraulic expansion at extreme pressures, creating a double-walled safety tube at the end. So if a tube defect occurs during operation of the heat exchanger, the medium first finds its way into the safety space and this is indicated by means of the plant monitoring system. In this way, defects may be detected immediately without a mixture of the two media occurring beforehand. So leaks can be detected early but may nevertheless be corrected at a later time in the course of planned maintenance.