In this series of articles we will look at the idea of heat transfer enhancement. The benefits of enhancement are that your heat exchangers will provide the same performance at a lower cost or provide better performance at the same or smaller overall size and footprint.

By Himanshu Joshi, Heat Exchanger Specialist, Lou Curcio, Heat Transfer Advisor, and Craig Thomas, Director of Technical Sales, NEOTISS Inc.

The use of finned tubing in the process industry has been a common practice for over 50 years. The criteria for when to consider this has been covered by Part 4 in this series. Dual-enhanced tubes, with both OD and ID fins, have been in common use in the AHR (air conditioning, heating, and refrigeration) market, especially refrigerant condensers and evaporators. However, it is only in the last ten years that dual enhanced tubes have entered the hydrocarbon and chemical processing industries. This article will explore three examples of how dual enhanced tubes are used in the Refining, Petrochemical and Chemical Process Industry to improve heat transfer efficiency and reduce capital expenditure. Refer to Parts 2-4 of this series of articles for background on controlling resistance, finned tubes, and dual-enhanced tubes.

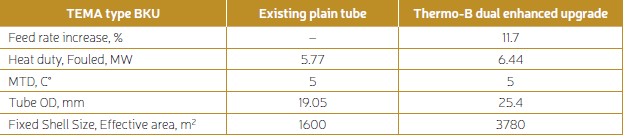

Case 1: Petrochemical plant fractionator feed chilling

A typical petrochemical manufacturing facility is comprised of a series of fractionators tasked with separating hydrocarbon mixtures according to their boiling points. Prior to entering a fractionator, process feed streams are commonly cooled with heat exchangers, maximizing efficiency in downstream separation. In this context, engineers were challenged to debottleneck an existing plant. The solution demanded innovative retrofitting of previously installed heat exchangers, making use of enhanced tube designs to extract greater performance from the existing equipment footprint, and thus minimizing capital expenditure. Comparing tube bundle designs showed that upgrading from plain tubes to the Thermo-B dual-enhanced tubes (Fig. 1) delivered a substantial boost in process throughput. Thermo-B tubes feature a modified fin structure on the outside diameter (OD) to enhance nucleate boiling at low temperature differences. This configuration allowed the plant to achieve a 12% increase in feed rate, illustrating that appropriate tube enhancements can improve heat exchanger efficiency by replacing only the existing tube bundle. Let’s take a closer look at the Thermo-B nucleate boiling tube. Reshaping low-fins to form micro-channels or cavities creates nucleation sites that allow bubbles to form at lower temperature differences than on smooth or standard low-fin surfaces. The resulting rapid movement of liquid and vapor at these nucleation sites provides for very high boiling heat transfer rates at a relatively low Mean Temperature Difference (MTD). The Thermo-B type of boiling surface was selected for this case in part because it has undergone rigorous third-party testing so the end client could perform their own design evaluation using commercial software tools.

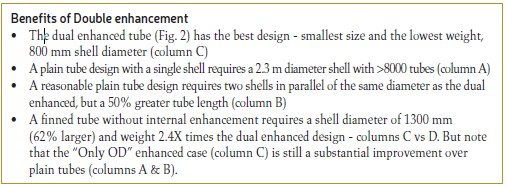

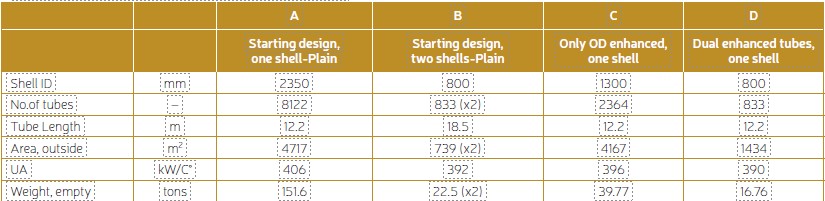

Case 2: Refinery feed effluent exchanger

This case study is for a reactor feed vs reactor effluent (feed/effluent) heat exchanger with hydrocarbon streams on both sides. The feed vaporizes to 100% vapor on the shell side and the effluent condenses from an all vapor state to about 50% vapor on the tube side, with both streams containing noncondensible gases. The heat exchanger is oriented vertically and has a single tube pass. With plain tubes, the size and weight of large or multiple shells present problems of maintenance, installation, and capital cost investment. Heat transfer enhancement can be used to improve on all of the above aspects. This particular service is prone to fouling and in a future article we will address how that might affect the selection of enhanced surfaces. The differences between a plain tube heat exchanger, one enhanced only on the outside, and one with dual enhancement, are presented in the tables 2 and 3. The comparison assumes that the same 35% margin on surface area (for fouling plus other purposes) is provided for all cases.

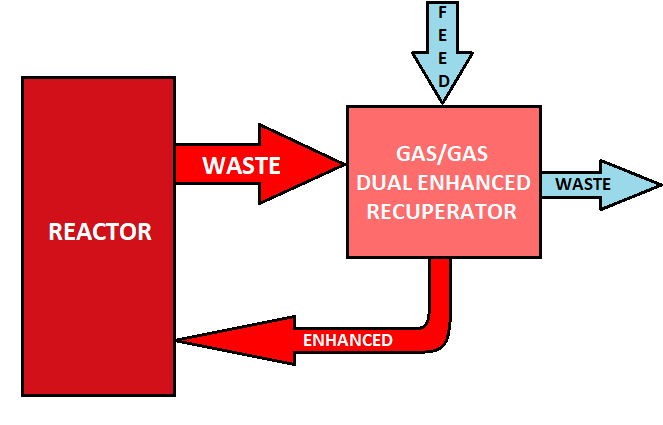

Case 3: Chemical plant recuperative heater

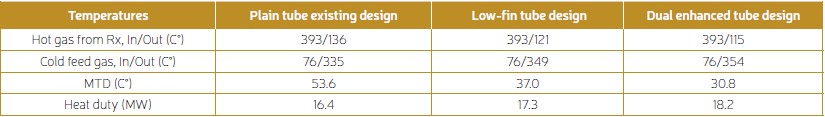

A typical recuperative heater uses waste heat from a furnace or reactor and recovers that energy to improve the efficiency of the reactor or furnace by preheating the feed gas. In this case, the end client had already installed a conventional plain tube heat exchanger but needed to achieve a higher feed gas temperature from the recuperator to improve efficiency and uptime on the reactor. Two improvement options were considered, one with low-fins and one with dual enhancement. Given that this was a gas/gas exchanger with roughly equivalent heat transfer coefficients on both the shell and tube sides, the dual enhanced tube option proved to be the optimal solution. Figure 3 shows the recuperator process and the Table 4 shows the increase in heat recovered achieved – a feed outlet temperature of 354 C° vs 335 C°.

Summary

This article has highlighted three examples of common heat exchange services that can benefit from the application of dual enhanced tubes in place of conventional plain and low-fin.

- In the case of a Petrochemical plant chiller, the Thermo-B tube enabled a 12% increase in feed rate, retaining the same heat exchanger size

- In the case of a refinery feed/effluent heat exchanger, dual-enhanced tubes resulted in the smallest design and the lowest weight.

- In the case of a recuperative heater, dual-enhanced tubes gave an 11% increase in heat duty and a 19 C° increase in feed preheat temperature.

There are numerous other opportunities to apply similar benefits. It should also be noted that the range of tube sizes (OD and wall) and material types available with dual enhanced tubes is more limited as compared to smooth or low-fin tube.

Upcoming in this series

In the next few articles we will look at other boiling enhancements, enhancements for condensing services, and how fouling might affect finned tube selection.

About the authors

Himanshu Joshi retired from Shell in 2021 after 34 combined years with ExxonMobil and Shell, during which he specialized in heat exchangers and fouling. He was part of a team that was granted a patent related to fouling deposit analysis at ExxonMobil, and led applied fouling R&D projects at both companies. He has made several presentations about the field aspects of fouling and fouling mitigation, and deployed many mitigation technologies in the field. He can be reached by email at alph.hmj@gmail.com.

Himanshu Joshi retired from Shell in 2021 after 34 combined years with ExxonMobil and Shell, during which he specialized in heat exchangers and fouling. He was part of a team that was granted a patent related to fouling deposit analysis at ExxonMobil, and led applied fouling R&D projects at both companies. He has made several presentations about the field aspects of fouling and fouling mitigation, and deployed many mitigation technologies in the field. He can be reached by email at alph.hmj@gmail.com.

Lou Curcio has over 30 years of experience in design, troubleshooting and repair of all types of heat exchangers. Leader of technology development projects and advisor for ExxonMobil’s global manufacturing teams. co-inventor of two U.S. patents and co-author of papers on enhanced heat transfer and fouling of heat exchange.

Lou Curcio has over 30 years of experience in design, troubleshooting and repair of all types of heat exchangers. Leader of technology development projects and advisor for ExxonMobil’s global manufacturing teams. co-inventor of two U.S. patents and co-author of papers on enhanced heat transfer and fouling of heat exchange.

Craig Thomas is currently the Director of Technical Sales for NEOTISS, Inc., a manufacturer of highperformance heat transfer tubing with operations in USA, France, China, and India. Craig has over 33 years of experience in applications engineering related to shell and tube heat exchangers. He is a member of the National Association of Corrosion Engineers, The Materials Technology Institute, Heat Transfer Research Inc., and The American Society of Heating, Refrigerating and Air-Conditioning Engineers. Craig has a degree in Engineering Science from Loyola University Maryland. He currently resides in Nashville TN.

Craig Thomas is currently the Director of Technical Sales for NEOTISS, Inc., a manufacturer of highperformance heat transfer tubing with operations in USA, France, China, and India. Craig has over 33 years of experience in applications engineering related to shell and tube heat exchangers. He is a member of the National Association of Corrosion Engineers, The Materials Technology Institute, Heat Transfer Research Inc., and The American Society of Heating, Refrigerating and Air-Conditioning Engineers. Craig has a degree in Engineering Science from Loyola University Maryland. He currently resides in Nashville TN.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in September 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.