Corrosion and incrustation are constant threats to heat exchangers, impacting performance and increasing costs. SÄKAPHEN, in collaboration with its trusted applicator, recently completed a major project for two Chinese heat exchanger manufacturers. By applying high-performance cold-cured linings, the team ensured long-term protection, efficiency, and reliability for the end user, Samsung E&A.

By Chiara Foppa Pedretti for SÄKAPHEN GmbH

Any company operating heat exchangers knows it: these systems run a high risk of corrosion and incrustation, which may cause a loss or drop in performance and lead to increased operating or investment costs. SÄKAPHEN and one of its trusted authorized applicators have recently completed another interesting project in this field, which proved once again that our cold-cured linings are among the best in class to safeguard thermal exchange equipment. This time, our coatings were required right across the world from our headquarters, as two Chinese heat exchanger manufacturers needed a high-performance product to be applied on their systems.

Project specifications

End user: Samsung E&A for a Baltic chemical company

HE manufacturers: Jiangsu JBPV Intelligent Equipment Co., Ltd and Wuxi Chemical Equipment Co., Ltd

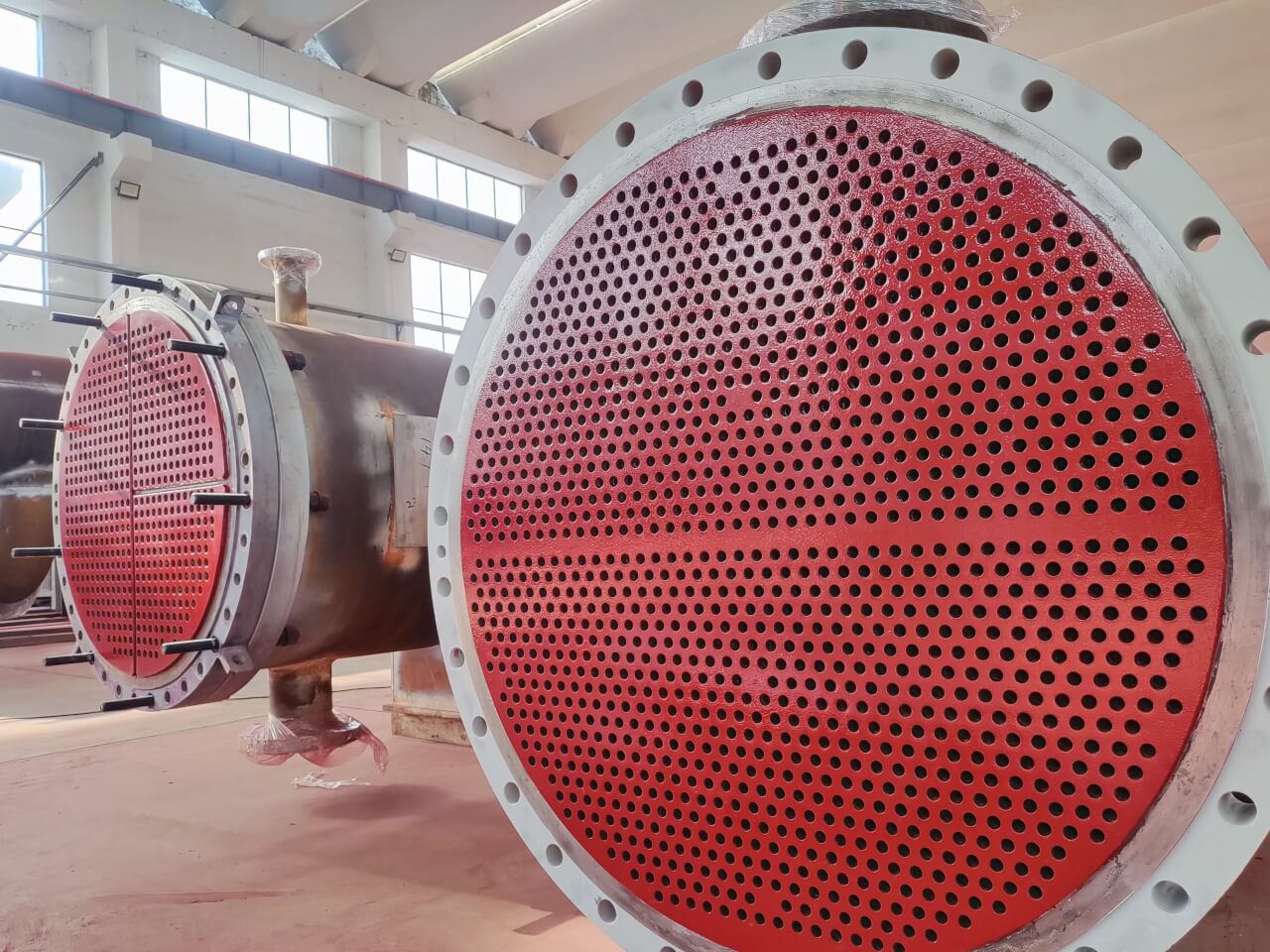

Items to be coated: Respectively, 27 shell and tube heat exchangers and 5 sets of floating-head heat exchangers. Lengths ranging from approx. 12 to 9 m, diameters from approx. 1.5 to 1.75 m. These heat exchangers are critical components in the chemical processing industry, where maintaining efficiency and durability under extreme conditions is essential for smooth operations and cost control.

Medium in contact: Cooling water of inconsistent quality at 60 °C on the tube side and high-pressure steam on the shell side (temperature of condensation: approx. 200 °C). The presence of variable water quality increases the risk of scaling and corrosion, while the high-pressure steam requires robust protection to prevent material degradation over time. Ensuring long-term resistance to these challenging conditions was a key priority in selecting the appropriate protective coatings.

Solution

1. Excellent application skills

Jiangsu Simijia Tank Container Service was SÄKAPHEN’s authorized applicator that took this project in charge. It has been one of our trusted partners since 2014 when we teamed up to provide the Chinese market with application services using our renowned linings. As always with SÄKAPHEN, the heat exchanger treatment process included the following steps:

- Preliminary analysis and technical consultancy

- Surface preparation (grit blasting and cleaning)

- Coating application until the achievement of the ideal DFT (dry film thickness) and curing

- QC, testing, and preparation of the required documentation.

2. Ideal coatings

SÄKAPHEN offers a wide range of coatings and linings to protect the surfaces of heat exchangers, condensers and coolers from the most varied industries (including power generation, chemical processing, petrochemical, refineries, natural gas processing and others) against corrosion, incrustation and fouling.

Two cold-cured linings were selected in this case: HR 60 Extra TG and SÄKATONIT K 80 LS. The key goal was protecting the heat exchangers’ tube sheets with their protruding tube ends.

SÄKAPHEN HR 60 Extra TG is a two-pack epoxy lining formulated to be chemically resistant to various acidic and strongly alkaline substances from inorganic salts and solutions, acidic aqueous liquids and all types of water including brackish, river and sea water up to 100 °C in permanent immersion. The lining is also resistant to water vapor diffusion (∆T 85 °C).

SÄKAPHEN SÄKATONIT K 80 LS is also a two-pack epoxy coating system resistant to all types of water in addition to various substances, including sour to strong alkaline, inorganic salts and their solutions. It also has outstanding hydrophobic properties and is resistant to temperature fluctuations. It can be used as a primer, putty, or a top coat, and it can be thinned down or thickened up depending on each application’s need, which also ensures cost reduction and waste minimization for more sustainable operations.

Final results

The customer was very pleased with the project’s results, as the applied coatings provided durable and effective protection for the heat exchangers, ensuring optimal performance in demanding conditions. The key benefits included:

- Excellent overall protection of the surfaces of the heat exchangers’ tube sheets and water boxes, preventing premature wear and extending equipment lifespan.

- Optimal prevention of caking, fouling, and incrustation, reducing the risk of blockages and maintaining efficient heat transfer rates.

- Long-term plant efficiency and reliability, minimizing unplanned maintenance and costly downtime.

- Outstanding ROI (return on investment), as the enhanced durability and performance of the coated surfaces reduced operational and maintenance costs over time.

- High-level corrosion prevention, safeguarding the integrity of critical components against aggressive environmental and process-related factors.

- Maximum operational safety, ensuring that the heat exchangers function without risk of leaks, failures, or efficiency loss, contributing to a stable and secure plant operation.

This project once again demonstrated the effectiveness of advanced cold-cured linings in protecting industrial heat exchangers, delivering a long-lasting solution tailored to the customer’s specific needs. For more visual representation, view the video on the case study version here.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in April 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.