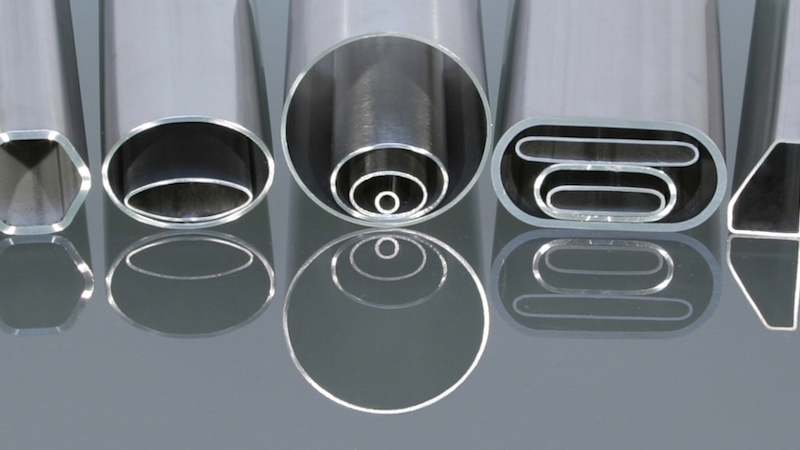

Hartmann Edelstahlrohre GmbH specialises in manufacturing individually shaped tubes with extremely tight tolerances. The wide variety of tube cross-sections reflects the company’s specialisation in providing customised solutions. All photos courtesy Hartmann Edelstahlrohre GmbH

While other companies focus on growth and expansion, Hartmann Edelstahlrohre GmbH invests in uncompromising quality. This small yet highly skilled team from Wilnsdorf, Germany, delivers results that even major corporations regard as remarkable. The company’s strengths lie in its in-depth expertise in material forming and advanced manufacturing technologies, its team of experienced specialists, and its state-of-the-art machinery.

By Iryna Mukha, Heat Exchanger World

Today, Hartmann is among the leading specialists for welded stainless-steel tubes. This success is the result of a clear principle: retaining as much expertise as possible in-house. “It has always been our ambition and motivation to do everything ourselves: production, sawing, punching, grinding, and bending, right down to sharpening the saw blades,” states Managing Director Manfred Hartmann. Every step, from toolmaking and welding technology to quality control and the associated technological testing, is carried out internally. According to the company’s principle, this is the only way to guarantee accuracy, reproducibility and innovation.

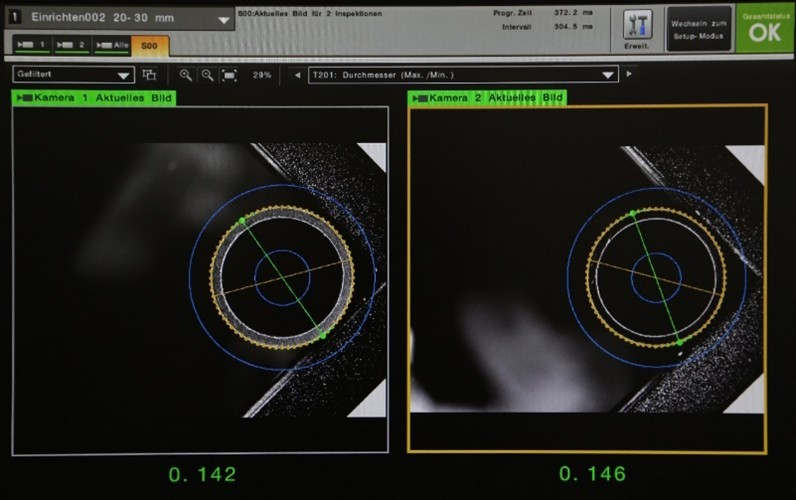

Hartmann Edelstahlrohre GmbH has been manufacturing stainless steel tubes using laser or TIG welding processes for well over 30 years. Tube dimensions range from 4 to 76,1 mm in diameter, with wall thicknesses from 0.5 to 4.0 mm. The tubes are cold-formed or inline annealed, with a maximum production length of up to 42 meters. Fixed lengths between 15 and 3,000 mm can be produced with a tolerance of ±0.1 mm. Fully automatic length measurements with 100 per cent optical cut edge inspection using high-resolution cameras enable quality assurance at the highest level.

For decades, grinding and polishing surfaces to a specific roughness has been part of the company’s standard product portfolio, ensuring compliance with the medical industry’s stringent quality requirements. From its Wilnsdorf site, the company supplies tubes for highly specialized applications in sectors such as the process industry, architecture, electrical engineering and apparatus engineering.

Three years of transformation: investing in independence, technology, and efficiency

The last three years have marked a period of impactful developments at Hartmann. This progress is rooted in a clear corporate philosophy that focuses on sustainability, independence and forward thinking. Implementation began in early 2022 with the full conversion of the company’s lighting to LED systems. In October 2022, the company replaced its fleet with electric and hybrid vehicles and installed its own charging infrastructure, powered by an in-house photovoltaic system. By the end of 2023, their nitrogen production plant was operational. In 2024, the first expansion stage of the photovoltaic system was completed, and in 2025, with the installation of an electrolysis system for hydrogen production, Hartmann completed the final step in its roadmap toward decarbonizing its energy consumption. Expanding solar energy is a key pillar of the company’s strategy. The aim is to ensure the company’s energy independence with the help of the most efficient and sustainable technologies possible. Since 2023, Hartmann has been producing solar power with a peak output of 420 kW on around 3,000 square metres of hall roof space. A battery storage system has also been installed to compensate for fluctuations in electricity availability.

In view of the company’s gas requirements, it has also invested in sustainable in-house production.

In June 2022, two compressor systems with heat exchangers were installed. Since then, the office and staff areas have been heated using waste heat from these units. “The hot oil from the compressors is fed through heat exchangers, which allows this heat to be utilised. It’s highly efficient and has completely eliminated our natural gas consumption,” explains Managing Director Simone Hartmann. Hartmann has also achieved independence when it comes to process gases: since September 2023, its own nitrogen production plant with a capacity of over 130,000 m³/year has been covering the entire annual demand for welding and annealing processes. It is powered by surplus electricity from the photovoltaic systems. In addition, Hartmann has built its own hydrogen plant, which went into operation in 2025. The capacity of this plant is designed so that electrolysis using surplus photovoltaic electricity during the weekend can cover the entire weekly demand for hydrogen.

Regarding technology, the company has invested in new testing and measurement systems, including a profile scanner for measuring the optical and physical geometry of tubes. In-line laser measurement of tube geometries has long been standard at Hartmann, and the eddy-current testing lines have been expanded. In 2024, the company developed and implemented an innovative optical weld seam scanner capable of detecting seam irregularities of less than 10 µm.

Self-reliant sustainability

Hartmann Edelstahlrohre is the first company in the Germany’s northwestern region of Westphalia to operate a fully CO2-free hydrogen and nitrogen supply. This is made possible by an intelligent combination of photovoltaics, electrolysis and closed-loop water recycling.

Around 20–30 percent of the company’s daytime energy demand are already covered by its own solar power. “Welding and annealing are energy-intensive processes. Accordingly, our electricity consumption is significantly higher than what we can cover with solar energy alone, even though our PV production is substantial,” explains Manfred. However, on weekends and public holidays, there is a surplus of solar power, which is used to produce nitrogen and hydrogen. The water required for electrolysis is reused after the electrolysis process and fed back into the manufacturing process. It is then used as cooling and service water for machines. Not a single drop is wasted.

Since commissioning in July 2025, over 8000 cubic meters of hydrogen and around 60,000 cubic meters of nitrogen have been generated on-site, fully CO2-neutral. “In the past, one or two trucks delivered gas every week. Today, we produce everything ourselves. This is not only environmentally friendly but also reduces heavy goods traffic on motorways and in the local industrial area,” adds Manfred.

The overall system is also economically sound. According to Simone Hartmann, the nitrogen generation system will achieve a return on investment within three years. Although the hydrogen plant will take six to eight years to break even, the managing directors did not have to worry about whether a bank would support the project, as these plants and all other investments were fully self-funded. “Independence has always been our top priority. We’re willing to make major investments for that. Long-term cost stability is the foundation of our future pricing reliability,” states the entrepreneurial couple.

Future plans are already in motion. Next, the 30-meter-high high-bay warehouse will be fitted with vertically mounted solar modules. Vertical solar modules are particularly effective in the winter months, as they benefit from the low-angled sunlight and avoid snow buildup. “We have created a mosaic in which all the pieces fit together: electricity, heat, gas, water. And every piece brings us closer to our sustainability goals and further away from fossil fuel dependencies,” says Manfred.

When quality becomes measurable

Although the past three years have been marked by heavy investment, Hartmann’s high-quality standards are nothing new. As early as 1996, the company was a pioneer in surface finishing with continuous measurement of roughness during the grinding process, which is particularly important for medical technology applications. Today, round tubes with tolerances of up to ± 0.05 mm are part of the company’s standard repertoire – a level that was previously reserved exclusively for seamless or drawn tubes.

The key to this quality standard lies with the company’s skilled employees who operate the equipment. All employees involved in pipe production are ET1, ET2 and ET3 certified. Inspectors use state-of-the-art microscopes for macroscopic and microscopic structural analysis, as well as equipment for chemical and technological material testing. This equipment can be used to perform hardness tests and determine mass fractions in duplex materials, for example.

Solid company culture

While many companies lament a lack of skilled labor, Hartmann Edelstahlrohre GmbH has a different story to tell. “We don’t face shortages because we consistently train our own people,” insists Manfred. The Company’s HR strategy is built on three pillars: Consistent development and promotion of young talent, active personal responsibility, and a corporate culture based on trust, closeness, and mutual appreciation.

For years, the family-owned company has provided training and apprenticeships in both technical and commercial fields. Beyond standard training, Simone and Manfred also promote extracurricular seminars, language courses, and soft-skill training such as “Confident Communication” and “Negotiation Techniques,” as well as early involvement in real business operations. “Our trainees are involved from the very beginning, even in meetings or negotiations, which are usually withheld from trainees in other companies,” shares Simone. “The learning effects are enormous, and the sense of responsibility grows early on as a result.”

Further training and qualifications for long-term employees are also systematically encouraged. All production staff hold at least, an ET1, ET2 and ET3 certification, which requires in-depth technical knowledge of physics. The ET3 certification is the highest qualification in this field. “Employee certifications in eddy-current testing, PT testing, and dual-degree programs in mechanical engineering are essential cornerstones for us. Likewise, advanced training in quality management in accordance with ISO 9001, as well as further training in metallurgy for the commercial and technical areas, are key qualifications for us,” adds Simone.

Short decision-making processes are essential at the Wilnsdorf-based company. Decisions are made collaboratively, challenges are addressed in a solution-oriented manner and resolved pragmatically. This culture of mutual trust fosters commitment and high levels of employee motivation. Simone sums it up: “The most valuable part of any company is its people. They are the ones who define the quality and quantity of our production.”

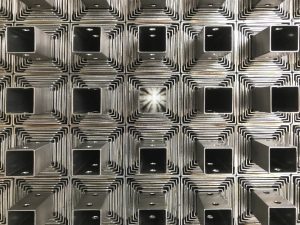

Duplex tubes from Hartmann

“We’ve developed our own formula to produce well calculated springback for duplex tubes. This formula is today’s standard in our production of forming tools to manufacture all of our stainless steel tubes even in other grades like lower Chromium-Nickel. The advantage of the produced tubes for example is the perfect roundness at the cutted edge of the tubes, without ovality. The holes in the tube sheets for heat exchangers can produced with much lower tolerances to fit in the tubes, at last with better welding-results at the end,” explains Manfred.

One more interesting market are tubes for high pressure fog mist systems. The tubes are used with 140 bar working pressure in fire-extinguishing systems. We produced in the past only for the PreFis-System over 1 Mio. m of such special tubes to be used in High-Fog-Systems with very special tolerances in diameter, yield-strength and pressure-resistance. The PreFis-System is today a part of the Tube-Mac-Company/Canada.

There are a lot of more other highly interesting projects like the telescopic-tubes used for lift-systems in TV-Studios.

Seven square tubes, longitudinally welded in the middle of the corner, fitted together as a telescope with tolerances of only 0,1 mm. The tubes can be telescoped up to lengths of 16,6 m. The telescopes are 100% tested and checked for functionality in a special test-area of Hartmann’s 30m high-bay storage.

Where others give up, our challenge begins

New projects and innovations at Hartmann arise from direct dialogue and are developed in close cooperation with customers. According to Manfred “We evolve with the requirements of our customers. Whether it’s a special profile, unusual dimensions or challenging specifications, where other back off, we take it on. Impossible doesn’t exist, unless it truly is impossible” is the motto practiced at Hartmann’s company.

Facts & Figures

|

|

| Company: | Hartmann Edelstahlrohre GmbH |

| Founded: | 1989 |

| Management: | Simone und Manfred Hartmann |

| Location: | Bochumer Straße 2 57234 Wilnsdorf |

| Products: | Longitudinally welded stainless-steel tubes using laser / TIG / plasma processes. Heat-exchanger, conduit, and structural tubes with maximal internal roughness of 0.8 µm, cold-formed or inline bright-annealed or pickled; surfaces metallically bright, ground or polished to defined roughness or gloss level; fixed lengths from 15–3,000 mm; 100% length and optical cut-edge inspection; maximum production length 42,000 mm |

| Tube types: | Round, elliptical, oval, profile, and custom-shaped tubes |

| Materials: | Cr, CrNi, duplex, and nickel-based alloys |

| Dimensions: | 4–120 mm cross-section |

| Wall thickness: | 0.5–4.0 mm |

| Standards & certificates: | 00W2 / DNV / DVGW / GL / TÜV-Einzelabnahmen |

| Contact: | Tel.: +49 2739 8960-0 E-Mail: mail@hartmann-edelstahlrohre.de |

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.