Corrosion, a natural electrochemical process, occurs when metals react with their surrounding environment, leading to the deterioration of the metal surface. In heat exchangers, corrosion can manifest in various forms, including pitting, crevice corrosion, galvanic corrosion, and stress corrosion cracking. The consequences of corrosion are far-reaching, extending beyond mere structural damage to compromising the thermal performance and operational reliability of heat exchangers.

By Omari Hussein Sabuni, Mechanical Engineer, Kinyerezi Power Plant

The implications of corrosion in heat exchangers are profound. Material degradation caused by corrosion reduces the structural integrity of heat exchanger components, compromising their ability to withstand operating conditions. Furthermore, corrosion-induced surface roughness and deposits impede heat transfer efficiency, resulting in increased energy consumption and decreased system performance. Ultimately, unchecked corrosion can lead to premature failure of heat exchangers, necessitating costly repairs or replacements and disrupting industrial processes.

Recognizing the critical importance of mitigating corrosion in heat exchangers, researchers and engineers are driven to explore innovative solutions that go beyond conventional corrosion protection methods. By harnessing cutting-edge technologies and materials, the goal is to enhance the performance, durability, and overall efficiency of heat exchangers while ensuring their long-term reliability.

In this context, this exploration delves into the forefront of corrosion protection for heat exchangers, examining advanced coatings, inhibitors, and materials that hold promise in combating corrosion. Furthermore, it explores emerging trends and future directions in corrosion control, emphasizing sustainability, smart technologies, and the integration of digital tools for proactive maintenance and prolonged service life of heat exchangers. Through these advancements, the quest for corrosion-resistant heat exchangers continues, paving the way for enhanced industrial productivity and energy efficiency.

Coatings

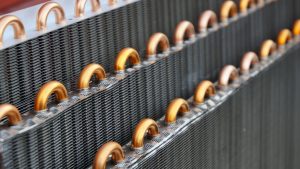

Coatings play a vital role in protecting heat exchangers from corrosion, serving as a barrier between the metal surface and the corrosive environment. Over the years, advancements in coating technology have led to the development of both traditional coatings and cutting-edge nano-coatings, each offering unique advantages in corrosion protection.

Traditional coatings

Traditional coatings, such as paints, epoxy, or polymer-based materials, have long been employed to safeguard heat exchangers from corrosion. These coatings form a physical barrier that shields the underlying metal from exposure to corrosive agents, such as moisture, chemicals, or gases. By preventing direct contact between the metal surface and the corrosive environment, traditional coatings effectively mitigate the risk of corrosion-induced damage.

An illustrative real-world example of traditional coatings in action can be found in the marine industry. Ships and offshore structures are constantly exposed to corrosive seawater, which can rapidly degrade metal surfaces if left unprotected. To combat this, heat exchangers and other critical components of marine vessels are coated with specialized marine-grade paints or epoxy coatings. These coatings not only provide excellent corrosion resistance but also offer additional benefits such as UV protection and fouling resistance, ensuring the longevity and operational reliability of marine heat exchangers.

Moreover, continuous advancements in formulation and application techniques have enhanced the durability and effectiveness of traditional coatings. For instance, the development of epoxy coatings with improved adhesion and chemical resistance has extended their lifespan in harsh operating environments. Similarly, the use of advanced polymer-based materials has led to coatings that exhibit superior resistance to abrasion, impact, and thermal cycling, further bolstering corrosion protection in heat exchangers.

Nano-coatings

In recent years, nanotechnology has revolutionized the field of corrosion protection by introducing innovative nano-coatings with unparalleled properties. Nano-coatings are engineered at the nanoscale, where materials exhibit unique physical and chemical characteristics, enabling them to outperform traditional coatings in terms of corrosion resistance and durability.

Nano-coatings offer several distinct advantages over their conventional counterparts. Firstly, their nanoscale structure provides a significantly higher surface area per unit volume, allowing for better coverage and adhesion to the metal substrate. This enhanced adhesion ensures long-term stability and prevents delamination or cracking of the coating, even under extreme conditions.

Secondly, nano-coatings exhibit exceptional resistance to corrosion due to their precisely engineered composition and morphology. By incorporating nanoscale additives such as nanoparticles, nanotubes, or nanoclays, these coatings create a robust protective barrier that effectively blocks corrosive agents from reaching the metal surface. Additionally, the tailored design of nano-coatings allows for customization based on specific environmental conditions, ensuring optimal performance and longevity in diverse operating environments.

A pertinent real-world example showcasing the effectiveness of nano-coatings can be found in the aerospace industry. Aircraft components, including heat exchangers, are subjected to highly corrosive conditions during flight, such as exposure to moisture, salt, and pollutants in the atmosphere. Nano-coatings formulated with corrosion-resistant nanoparticles, such as zinc oxide or titanium dioxide, are applied to critical aircraft parts to provide exceptional protection against corrosion. These nano-coatings not only enhance the durability of heat exchangers but also contribute to the overall safety and reliability of aircraft operations.

Inhibitors

In the relentless battle against corrosion in heat exchangers, inhibitors emerge as essential warriors, aiming to suppress the electrochemical processes that threaten the integrity of metal surfaces. This category encompasses both traditional chemical inhibitors and the cutting-edge realm of smart inhibitors, each designed to tackle corrosion through distinct mechanisms.

Chemical inhibitors

Chemical inhibitors serve as stalwart defenders by being introduced into the heat transfer fluid, where they tirelessly combat corrosion at the molecular level. These inhibitors function by either forming a protective film on the metal surface or by intervening in the electrochemical reactions that initiate corrosion. The protective film acts as a barrier, shielding the metal from the corrosive environment and hindering the progression of corrosion. Alternatively, inhibitors may alter the electrochemical processes by either reducing the corrosion rate or preventing the initiation of corrosion altogether.

A real-world application of chemical inhibitors can be witnessed in the oil and gas industry, where pipelines and heat exchangers are exposed to harsh conditions, including corrosive fluids and high temperatures. Corrosion inhibitors, often formulated with compounds like amines or phosphates, are injected into the fluid systems to safeguard against corrosion. These inhibitors create a protective layer on the internal surfaces of pipes and heat exchanger tubes, preventing corrosion-related damage and ensuring the longevity of these critical infrastructure components.

As ongoing research endeavors continue to push the boundaries of corrosion inhibition, the focus lies on developing inhibitors that not only exhibit enhanced efficacy but also align with environmental sustainability goals. The quest for more effective and environmentally friendly inhibitors has led to the exploration of novel compounds and formulations that strike a balance between robust corrosion protection and minimal ecological impact.

Smart inhibitors

In the era of intelligent materials, researchers are delving into the realm of smart inhibitors, aiming to revolutionize corrosion protection by endowing inhibitors with adaptive capabilities. These responsive inhibitors are designed to sense and react to changing environmental conditions, thereby providing targeted and on-demand corrosion protection.

Smart inhibitors operate on the principle of responsiveness to external stimuli such as temperature, pH levels, or other environmental factors. When exposed to specific triggers indicative of corrosive conditions, these inhibitors release protective agents or undergo a transformation that enhances their inhibitive properties. For instance, in an environment with fluctuating temperatures or varying pH levels, a smart inhibitor could adapt its protective mechanism accordingly, offering tailored defense against corrosion under diverse conditions.

A pertinent example of smart inhibitors can be found in industrial settings where heat exchangers are employed in processes characterized by dynamic operating conditions. By incorporating smart inhibitors into the heat transfer fluid, the system gains the ability to adapt to changes in temperature, pH, or other factors, ensuring that corrosion protection remains effective even as environmental conditions evolve.

Advanced materials

In the quest for robust corrosion protection in heat exchangers, the exploration of advanced materials stands at the forefront, offering innovative solutions to withstand the challenges posed by corrosive environments. This category encompasses the development and utilization of corrosion-resistant alloys as well as the exploration of composite materials that blend the strengths of metals with the corrosion resistance of polymers or ceramics.

Corrosion-resistant alloys (CRAs)

Corrosion-resistant alloys represent a pioneering approach to fortifying metals against the relentless forces of corrosion. This involves the meticulous engineering of metal alloys with inherent resistance to specific corrosive environments, ensuring that the material can withstand exposure to aggressive substances over prolonged periods. Commonly employed CRAs in the realm of heat exchangers include stainless steels, nickel alloys, and titanium.

Stainless steels, renowned for their chromium content, form a passive oxide layer on their surface, rendering them highly resistant to corrosion in various atmospheric and aqueous conditions. Nickel alloys, with their exceptional corrosion resistance and mechanical properties, find applications in environments where severe corrosion challenges persist. Titanium, celebrated for its exceptional strength-to-weight ratio and remarkable corrosion resistance, is a staple in heat exchangers deployed in aggressive chemical processing and marine applications. A tangible example of the application of CRAs can be observed in the chemical processing industry, where heat exchangers are exposed to corrosive fluids with varying chemical compositions. In such settings, heat exchangers constructed from nickel-based alloys or titanium demonstrate unparalleled resistance to corrosion, ensuring the integrity of the equipment and longevity of the operational processes.

Composite materials

Researchers are pushing the boundaries of material science by exploring composite materials that seamlessly amalgamate the mechanical robustness of metals with the corrosion-resistant attributes of polymers or ceramics.

These hybrid materials aim to strike a delicate balance between mechanical strength and corrosion protection, offering a versatile solution for diverse applications, including heat exchangers.

Composite materials often feature a matrix of metals reinforced with polymers or ceramics, leveraging the unique properties of each component. The metal component contributes strength and structural integrity, while the non-metal component provides enhanced corrosion resistance. This synergistic combination results in materials that not only withstand the mechanical stresses of operation but also resist corrosion in harsh environments.

In real-world scenarios, composite materials find applications in industries where aggressive corrosion and demanding mechanical requirements coexist.

For instance, in seawater desalination plants, heat exchangers crafted from composite materials can effectively combat both the corrosive nature of saltwater and the mechanical stresses induced by high-pressure fluid flows. This illustrates the adaptability and potential of composite materials to address the dual challenges of corrosion and mechanical durability in complex operational settings.

Future trends

The landscape of corrosion protection for heat exchangers is evolving, and future trends are shaped by a commitment to sustainability, technological innovation, and a proactive approach to maintenance. Emerging trends include the development of green corrosion inhibitors, the application of advanced electrochemical techniques, and the integration of digital technologies for real-time monitoring and predictive maintenance.

Green corrosion inhibitors

As industries increasingly prioritize environmental sustainability, there is a notable shift towards the development of green corrosion inhibitors. These inhibitors are derived from renewable and natural sources, aiming to replace traditional chemical inhibitors with biodegradable and non-toxic alternatives. The emphasis on sustainability aligns with the global push for eco-friendly practices in industrial processes.

A real-world example of this trend can be seen in the agriculture sector, where heat exchangers are employed in various processes, including crop drying and storage. Green corrosion inhibitors, derived from plant extracts or other environmentally benign sources, are gaining traction in these applications. These inhibitors not only provide effective corrosion protection but also contribute to the overall sustainability of agricultural operations.

Electrochemical techniques

Advancements in electrochemical techniques are revolutionizing the monitoring and control of corrosion in heat exchangers. Techniques such as impressed current cathodic protection and electrochemical impedance spectroscopy offer real-time insights into the corrosion processes, enabling a proactive approach to corrosion management. These methods allow for precise control and adjustment of protective measures based on the evolving corrosion conditions.

In the maritime industry, where heat exchangers on ships are constantly exposed to corrosive seawater, electrochemical techniques play a crucial role. Impressed current cathodic protection systems are employed to safeguard critical components, such as heat exchanger tubes, by applying a controlled electrical current to counteract the corrosive effects of seawater. This approach not only extends the lifespan of the heat exchangers but also minimizes maintenance efforts and associated costs.

Digitalization and predictive maintenance

The integration of digital technologies, including sensors and data analytics, represents a paradigm shift in corrosion management for heat exchangers. Real-time monitoring of corrosion rates and overall heat exchanger health allows for early detection of potential issues. Predictive maintenance strategies, informed by data collected from sensors, enable proactive interventions to address emerging corrosion threats, reducing downtime and extending the operational lifespan of heat exchangers.

In the energy sector, where heat exchangers play a crucial role in power plants, digitalization is transforming maintenance practices. Sensors embedded in heat exchangers continuously monitor corrosion parameters, and data analytics algorithms predict potential failure points. This predictive maintenance approach allows for targeted interventions, preventing unplanned shutdowns and optimizing the overall efficiency of power generation facilities.

Conclusion

The innovation in corrosion protection for heat exchangers involves a multidisciplinary approach, incorporating advancements in coatings, inhibitors, and materials. Future trends emphasize sustainability, smart technologies, and the integration of digital tools for enhanced corrosion control and prolonged heat exchanger operation.

About the author

About the author

Omari Hussein Sabuni is an experienced mechanical engineer at Kinyerezi Gas Power Plant, specializing in heat exchanger design, optimization, troubleshooting and providing practical solutions for various heat exchanger problems. He is skilled in analyzing thermal systems and developing innovative solutions to enhance heat transfer efficiency and adept at conducting feasibility studies, performing risk assessments, and ensuring compliance with industry standards.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in February 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.

About the author

About the author