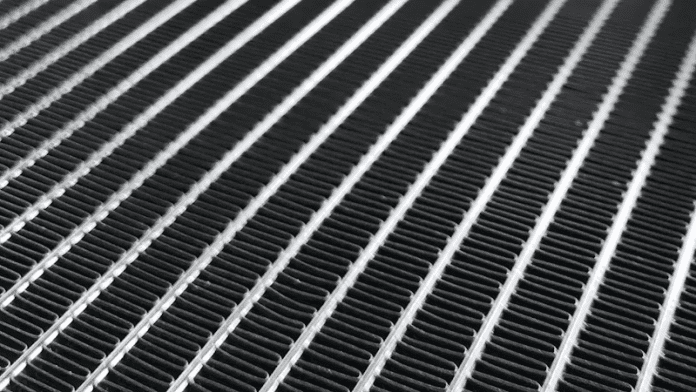

Aluminium is a cornerstone material in microchannel heat exchangers, valued for its lightweight and corrosion-resistant characteristics. However, safeguarding its longevity is crucial. This is where advanced nanoscale coating technology, newly deployed by Kaltra, emerges as a groundbreaking solution, providing unparalleled protection and extending heat exchangers’ performance life.

The protection capabilities of nanoscale coating closely match those of electrophoretic epoxy coating (e-coating) while offering several distinct advantages: (i) With a thickness of less than 5µm, nanoscale coating preserves the heat exchanger’s thermal conductivity and tubeside pressure drop. (ii) It provides UV protection, safeguarding the exchanger from harmful ultraviolet exposure. (iii) Its hydrophobic properties facilitate easy condensate removal and help maintain coil cleanliness over time.

Kaltra performed SWAAT tests on microchannel heat exchangers treated with nanoscale coating using two aluminium alloy compositions: 3F03 Alloy and 3F05 Alloy.

In addition, nanoscale coating significantly enhances the allowable operating range of microchannel heat exchangers by temperature resistance and fluid compatibility.

These advancements ensure greater versatility and durability across diverse operating conditions.