The Korea Institute of Energy Research (KIER), based in Daejeon, South Korea, has developed a low-temperature refrigeration technology that uses air (R729) as a refrigerant and incorporates a “compander” system, which combines a compressor, heat exchanger and expander.

KIER’s air-based cooling system leverages what is called the reverse-Brayton cycle. Under the reverse-Brayton cycle, air is compressed to a high temperature and high pressure; the compressed air is passed through a heat exchanger, where it is cooled down to a low temperature while maintaining high pressure; the cooled, high-pressure air is then expanded in an expander, reducing it to a low temperature and low pressure. The cooled air is then delivered to the required area for cooling.

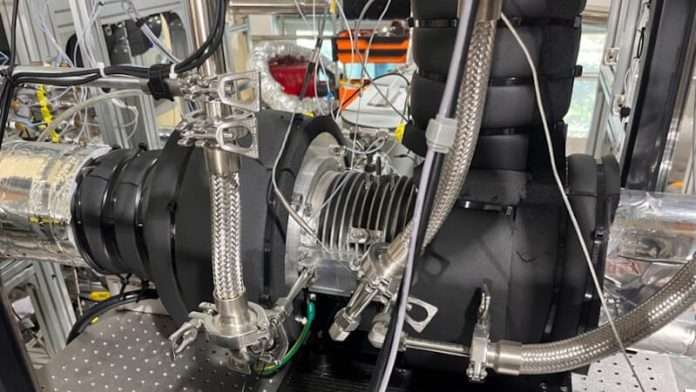

To implement the reverse-Brayton cycle system, the research team devised a compander system that connects the compressor, expander, and motor on a single shaft. The shaft system design ensures stable operation even at ultra-high rotational speeds, further enhancing the reliability and performance of the system.