Heat exchangers are a cornerstone of industrial thermal management, especially in the chemical and energy sectors. Among these, shell-and-tube heat exchangers (SHTX) are a preferred solution due to their mechanical robustness, ease of maintenance, and high heat transfer efficiency. Traditional design relies heavily on empirical correlations, but these approaches fall short when faced with unconventional geometries or operating conditions.

By Harlley Parno & Benjamin Turner, LATTICEPT

To address the aforementioned limitations, advanced computational tools like M-Star CFD are paving the new way engineers analyze and optimize heat exchanger performance. By leveraging the lattice Boltzmann method (LBM), M-Star CFD enables rapid and accurate simulations of complex fluid dynamics and heat transfer, all powered by modern GPUs. Recently, Thomas et al. (2024) conducted extensive validation of a generalized approach for the calculation of convective heat transfer coefficients across multiple industrially applicable geometries: agitated tanks, pipe flow systems, cylinders in crossflow, and tube bundles. The authors validated the method implemented against expectations from experimentally derived empirical design correlations for SHTX.

Why use M-Star CFD for heat exchangers

M-Star CFD is purpose-built to take advantage of the GPU’s parallel processing capabilities, offering dramatic reductions in computational time compared to traditional finite-volume methods (FVM). Unlike FVM, which relies on solving differential equations, the LBM simulates fluid behavior as interactions between particle-like elements. This method simplifies grid generation and allows for more natural modeling of turbulence, a critical factor in heat exchanger performance.

Recent studies have shown that M-Star CFD can deliver high-fidelity results for heat transfer and pressure drop in SHTX designs while significantly reducing computational overhead. A key innovation is its use of a generalized convective heat transfer coefficient approach, which eliminates the need for near-wall turbulence models. Instead, local energy dissipation rates in the bulk flow are used to compute heat transfer coefficients, streamlining the simulation process.

Simulating shell-and-tube heat exchangers

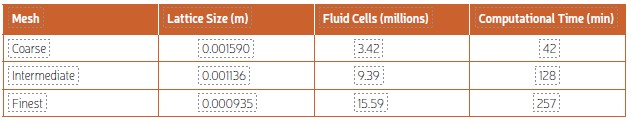

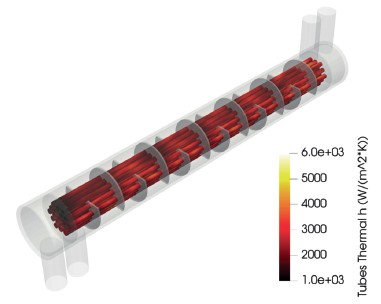

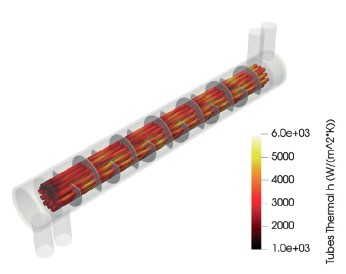

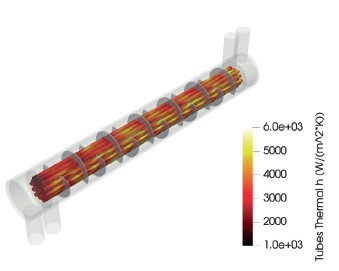

In this study, a shell-and-tube heat exchanger was simulated under various flow rates using M-Star CFD on an NVIDIA RTX 3090 GPU. Three different grid resolutions were tested to balance accuracy and computational cost. The intermediate resolution proved to be the optimal choice, achieving results within 10% of experimental data while maintaining reasonable runtimes. To ensure accurate predictions, a “wall function” model was applied. This method smooths boundary layer interactions and reduces numerical artifacts associated with traditional grid-aligned boundary conditions. The results were benchmarked against experimental data and demonstrated excellent agreement for both pressure drop and heat transfer coefficient predictions. A fixed flow rate of 0.00222 m³/s was specified at shellside inlet and a 0 psig pressure boundary condition was prescribed at the shellside outlet. Water with a kinematic viscosity of 1e–6 m2/s and a density of 1000 kg/m3 was used for the fluid properties. All simulations were performed on an NVIDIA RTX 3090 GPU, with each simulation running for a total of 10 seconds, discarding the first 5 seconds to eliminate initial transients during startup. A time-averaged analysis was then performed over the remaining 5 seconds. In addition to these numerical studies, the intermediate lattice size was chosen to evaluate the entire range of volumetric fl ow conditions experimentally reported by Chen et al., 2019. Initially 3 m3/h, increasing 1 m3/h every 5 s until reaching 7 m3/h.

Key findings

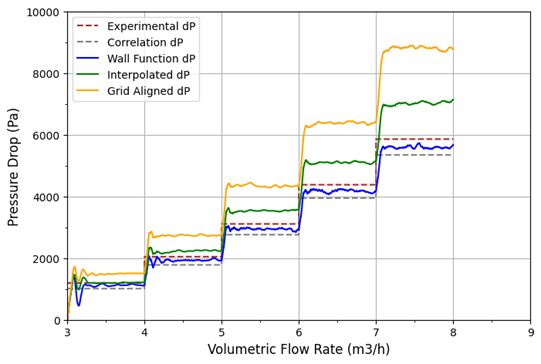

The results of the pressure drop in the shell side of the heat exchanger are presented below.

- Pressure drop: Simulations using the wall function model closely matched experimental values across a range of fl ow rates, outperforming traditional grid-aligned and interpolated boundary conditions. This is critical for ensuring realistic energy requirements in industrial systems.

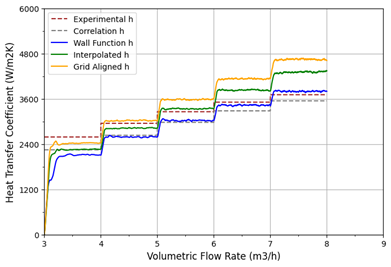

- Heat transfer: The wall function model also excelled in predicting heat transfer coefficients, showing deviations of less than 10% from experimental values at higher flow rates. The approach effectively captures local heat transfer variations, offering deeper insights into exchanger performance.

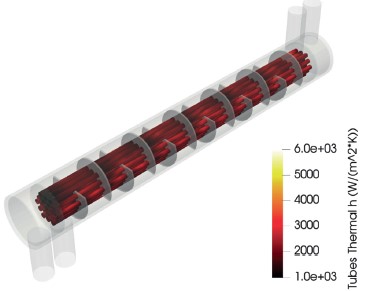

- Local heat transfer coefficients: One standout feature of M-Star CFD is its ability to resolve local heat transfer coefficients across the entire surface of the heat exchanger. This provides engineers with detailed insights into where heat transfer is most efficient and where potential bottlenecks exist. By visualizing these localized variations, designers can pinpoint areas for optimization, such as improving flow distribution or modifying tube and baffle arrangements. This level of granularity is invaluable for enhancing overall performance, ensuring uniform heat transfer, and addressing any potential inefficiencies in the system. Additionally, this capability supports predictive maintenance by identifying regions prone to fouling or performance degradation over time.

Practical implications

The ability to simulate transient flow phenomena opens up new possibilities for optimizing heat exchanger designs. Engineers can now assess the impact of varying operating conditions or geometric modifications with unprecedented speed and precision. Moreover, the local heat transfer coefficient distributions provided by M-Star CFD enable targeted improvements, such as optimizing baffle placement or tube arrangements M-Star CFD demonstrates its potential as a transformative tool for the heat exchanger industry. Its combination of GPU-accelerated performance, robust turbulence modeling, and innovative heat transfer coefficient calculations makes it an invaluable resource for engineers looking to push the boundaries of design and efficiency. As the industry continues to embrace digitalization, tools like M-Star CFD are set to become essential for staying ahead of the curve. For more information visit www.latticept.com and www.mstarcfd.com.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in March 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.