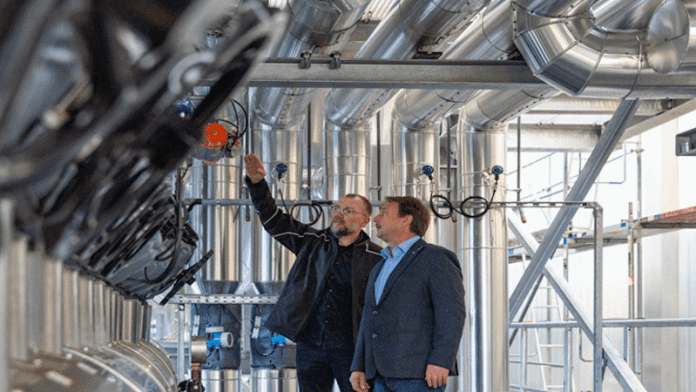

The Orafol Group has chosen Dürr’s advanced energy-efficient environmental technology for its operations. A new regenerative thermal air pollution control system will be used to purify the solvent-rich exhaust air from a newly constructed 14,000 m² production hall, which is dedicated to laminating and coating special films and adhesive tape systems.

The new RTO system was delivered as a turnkey project, encompassing development, design, production, installation, and commissioning.

The new RTO is Dürr’s major installation for Orafol to date. Previously, two large coating systems were connected to a common air pollution control system – now it’s three. A key innovation is the advanced energy management system, which includes two specialised modules: XtraBalance equalises temperature differences between the three RTO media chambers packed with ceramic heat exchange material. XtraControl establishes an overall “average system temperature” and monitors it through multiple sensors in the heat exchange tanks and combustion chamber, using the data to control the system. Together, these modules ensure reliable and trouble-free operation, high system availability, and uniform conversion of released energy into usable thermal energy for production. This further reduces operating costs and enhances resilience, even under highly fluctuating operating conditions.