Paul Meijering has positioned itself as a reliable partner in the stainless steel industry, earning a reputable status for its steadfast commitment to quality and relationship building. As enduring pioneers, the company has been instrumental in delivering superior products and innovative solutions that cater to various industrial needs. Their pursuit of excellence, dedicated approach to nurturing customer relationships, and innovative practices continue to ensure sustainable success year after year. The Heat Exchanger World team met with Paul Meijering himself in order to uncover the meticulous strategies he and his team employ to maintain their leadership in the market.

By Iryna Mukha, Heat Exchanger World

The root of success

Paul Meijering, a well-established presence in the stainless steel supply and distribution realm, showcases over three decades of expertise. With an approach that separates his company from the competition, Paul’s innovative way of doing business involves a single-minded vision rather than emulation of competition. Today, his Netherlands-based company dispatches a variety of corrosion-resistant alloy tubes, pipes, fittings, with a portfolio covering more than 11,000 articles in ten distinct grades worldwide. Their commitment to excellence is reflected in continuous investments in technology, equipment, and human resources.

Paul’s primary business involves serving stockists globally “For over 30 years, we’ve supplied directly to stockists. When they place an order, we transport it directly to their customers. The orders arrive in unmarked trucks with our customer’s name on the packing list,” says Paul.

With profound insights into the industry’s intricacies, Paul has always prioritized customer communication and satisfaction. The approach is simple yet effective – resolve the problem first, then discuss the cause. This focus on ensuring customer satisfaction remains paramount.

What sets Paul’s company apart is their unwavering commitment to swift order dispatch, ensuring every order is sent out the same day it arrives. He promises: “Everything is done within 5 minutes.” This efficient approach consistently surprises customers with the speed of delivery; an order placed at 16:30 will be at the customer’s doorstep by 06:30 the following morning. The secret lies in meticulous organization and leveraging cutting-edge technology.

In the case of sizable orders, customers are promptly contacted to ascertain priority items. These urgent items are expedited, while the remaining order is scheduled to arrive precisely when the customer requires them. This attention to order fulfillment optimizes their customers’ receiving processes and is highly valued by them. Ultimately, Paul Meijering’s mentality is simple: “We never refuse an order. Nothing is a challenge.”

Cutting-edge technology

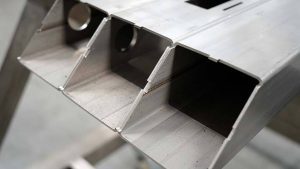

Investments in the workplace for better ergonomics and efficient order fulfillment have been prioritized. Automated order-picking machinery quietly assembles individual items into whole batches, readied for packaging and dispatch. Overhead cranes delicately handle pipe bundles, conveying them from the laser cutters to packaging, and then on to awaiting trucks.

An expansion of the warehouse was also a significant investment over the past two years. Designed to accommodate the bustling cut-to-length tube business, the expanded facility is now operational. Equipped with an automatic storage and picking system, pipes are conveniently moved to the sawing department. “Cut-to-length pieces have become a significant part of our business,” Paul explained.

The acquisition of the new tube laser cutter has allowed them to boost quality and turnover simultaneously. Given that tubes and fittings are the crux of the business, having cutting-edge technology is crucial. Paul believes in having ample space for future expansion, hence the company’s facilities are generously sized.

“At first, our customers started using the laser for their needs elsewhere, so we decided to do it for them because the other places they went to were doing it wrong. We laser right away according to each order and we don’t charge extra for fast turnaround,” Paul noted. This customer-centric approach has endeared the firm to its clientele, ensuring that they receive swift service without compromising on quality. This commitment to excellence and customer satisfaction continues to drive their innovative strategies and operational enhancements.

In their pursuit of seamless ordering and elimination of any possible human error, Paul Meijering expects to have a new digital ordering system to become operational within the next 2 years. Expanding on the advancements, Paul emphasized the significant improvements that have come with the investment. “Everything we’ve done reflects our commitment to precision and efficiency,” he said. The enhanced workspace and state-of-the-art machinery underscore their dedication to meeting client needs with unmatched quality and speed.

Dedication to excellence

During COVID times, the company achieved what seemed to be impossible at the time – they doubled their turnover. They were quick to capitalize on such momentum and keep delivering record-breaking performances year after year. “We focus on maintaining high service standards, rather than seeking aggressive expansion. If a customer decides to try a lower-priced option, we simply wish them well and wait for them to come back. Our commitment to quality doesn’t stop at product certification; we ensure quality at every step of our supply chain.”

Paul’s emphasis on quality is evident in how they handle product reception, storage, tracking, packaging, and delivery. New arrivals of tubes and fittings are unloaded swiftly and thoroughly inspected. Checks start with verifying the packaging and its content visually – assessing for damage, checking quantity per crate, matching heat number and grade stamp with the shipping documents.

They also use a portable chemical analysis monitor to confirm the pipes’ stated composition. Wall thickness is measured with callipers, while an endoscope is used to check clean interiors of smaller tubes. Finally, tubes are weighed before storing as tubes of the same size have a constant weight which is a good measure of the number stored or retrieved later. They are then methodically stored in one of the numerous locations using an automatic tube stacker.

The order department is an immaculately clean, open area, efficiently operated by multiple hefty Hänel Lean-Lifts, and a towering Fehr Honeycomb storage system. When a local computer terminal selects an order, a Lean-Lift springs into action. A few seconds after, an illuminated arrow points to a compartment within a large tray where the required items are located. The operator ensures the right number of parts are packed appropriately, with remaining stock confirmed instantly. Once the items are correctly identified and counted, they are sensitively packed and labelled, so the contents are clear to the recipient. Larger orders have their components protected with bubble wrap or foam placed inside suitable packaging to avoid transit damage. Individual pipes are kept straight using a wooden plank before being fully wrapped in plastic.

As Paul explains, “We stand out among suppliers as we own our truck fleet and employ all our drivers, ensuring they handle the products with care, unlike regular transport companies who may not have specialist knowledge in dealing with stainless steel products and resort to using forklifts. Forklifts, in my experience, are a recipe for order damage. A more reliable method of loading stainless steel products is to use an overhead crane.”

Sustainable from day one

When Paul discusses the topic of sustainable materials in the present market, he beams with pride. “More than 90% of the stainless steel we transport originates from recycled material. We operate in a self-sustaining industry. Each item is destined to be melted down and reused for the creation of new products.”

The facility’s commitment to the environment is unwavering. The cardboard boxes used for the shipment of smaller articles are collected and reused from local businesses. Paul is unperturbed by the presence of other companies’ logos on these boxes. “No products have our name on it,” he says. This only further underscores the company’s commitment to letting their efficiency do the talking instead of flashy branding.

Wooden boxes that arrive packed with goods are diligently reorganized for further use, and those that have borne damage are shredded and subsequently recycled. The plastic fastenings used to group pipes together are produced using 100% recycled plastic. Their Zaltbommel location is generously equipped with 1,100 solar panels, which generated an impressive 98% of its energy needs through solar power in 2023.

In keeping with their commitment to sustainability, all company vehicles are powered by electricity or run on eco-friendly HVO 100 diesel. This includes their modern truck fleet, signaling the company’s dedication to reducing their carbon footprint and promoting sustainable practices.

Investing in people

At Paul Meijering, the team works smoothly and efficiently. Even when orders come in fast and deadlines are tight, there’s a sense of calm throughout the facility. This is because of well-designed systems that help everything run smoothly. Paul Meijering himself believes in making things easy for both customers and staff, saying: “All our systems are made to help customer and staff. There’s pretty much no room for human error.” And it shows—mistakes are very rare here.

The company also values teamwork and encourages the growth and training of each employee. Everyone gets to learn all the important processes in the company, not just their own tasks. This makes the team very flexible, allowing them to switch roles and help out wherever needed. From manufacturing to management, every team member is ready to step in and contribute. This approach is a big part of why the company is successful and runs so well.

Forward thinking

Paul has his gaze firmly fixed on the future, guided by the mantra, “I never look at today, I look at where I want to be in 10 years.” He has grand plans on the horizon, with the intention of fully implementing automation in ordering and slicing systems to expedite the dispatch process. His relentless pursuit to advance in digitalisation is unmistakable, a testament to his commitment to continual investment in this sphere.

Tools like their laser cutters underscore this dedication – simply entering the drawings immediately generates a customer price. “Welcoming tech enables us to deliver superior-grade products swiftly and competently, reaffirming our ultimate goal – customer satisfaction. Regardless of their location or the size of their order, every customer is priority,” concludes Paul.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in September 2024. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.