SACOME has recently supplied a heat exchanger intended for heating milk concentrate with a dry extract of 45%, for a flexible production capacity between 3,000 and 6,000 kg/h.

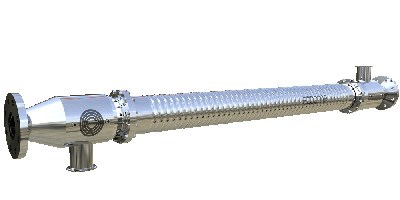

For a product of such high consistency, the solution that offers the best performance is an annular space heat exchanger; In this case, among the different alternatives offered by its range of tubular heat exchangers, it recommends to its client the S-TF40R-D annular space heat exchanger with radial product inlet.

To optimally preserve the organoleptic characteristics of this dairy product, its client needed the deltaT (or temperature difference between the hot water and the pasteurization temperature of the concentrate) to be less than 2°C. Therefore, its technicians have taken into account this parameter for sizing the tubular heat exchanger and calculate the necessary exchange area.

In addition, the supplied heat exchanger, like all the equipment in its range of annular space heat exchangers, is completely removable, which will greatly facilitate inspection and cleaning tasks for its client.