Vapor-liquid separation is a critical process in heat exchangers and chemical engineering systems, ensuring operational efficiency, equipment longevity, and product purity. Entrainment of liquid droplets in vapor streams can lead to issues such as fouling, corrosion, reduced thermal efficiency, and downstream contamination. Two widely used solutions—splash baffles and demisters (mist eliminators)—address this challenge with distinct mechanisms and applications. This article compares their functionality, benefits, challenges, and optimal use cases, providing insights for engineers to select the right approach for specific system requirements.

By Ali Dehghani, Junior Mechanical Engineer, and Sara Kafashian, Senior Mechanical Engineer, EIED

In heat exchanger systems, particularly kettle-type designs, and in chemical process equipment like knockout drums and scrubbers, effective separation of vapor and liquid phases is essential. Without proper separation, entrained liquid droplets can escape with the vapor, causing performance degradation, increased maintenance costs, and potential damage to downstream equipment. For example, in heat exchangers, liquid carryover can reduce heat transfer efficiency, serious mechanical damages to compressor in refrigeration systems, while in chemical plants, it may contaminate products or corrode pipelines. Splash baffles and demisters serve as key tools to mitigate these risks, each offering unique advantages.

Splash baffles: Functionality and applications

How splash baffles work

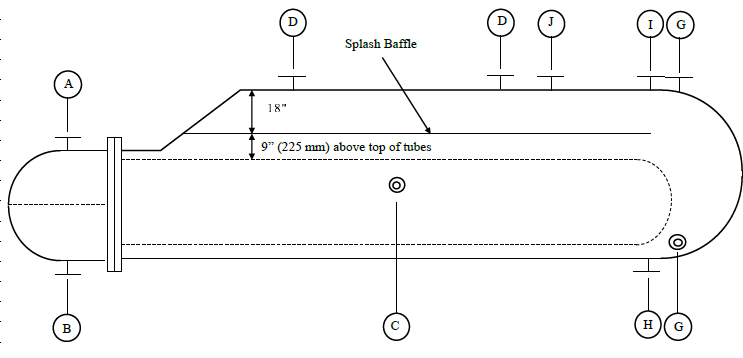

Splash baffles are passive internal components strategically placed within kettle-type heat exchangers to enhance vapor-liquid disengagement. Positioned above the tube bundle, they promote turbulence in the vapor stream, encouraging heavier liquid droplets to collide, coalesce, and settle back into the liquid phase. This prevents larger droplets from being carried into the vapor outlet, reducing entrainment. To ensure effective separation, the maximum horizontal vapor velocity in the vapor space above the splash baffle must be controlled to prevent re-entrainment of liquid droplets. The velocity should not exceed:

- V(ft/min) ≤ 20 √(ρ_l / ρ_v) for velocity in feet per minute, or

- V(m/s) ≤ 0.1016 √(ρ_l /ρ_v) for velocity in meters per second,

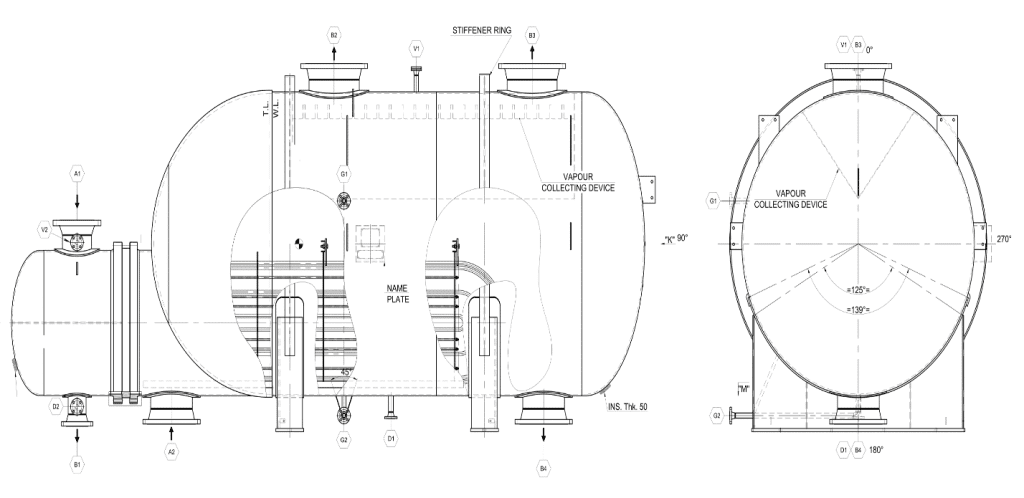

where p_l is the liquid density and p_v is the vapor density (both in consistent units, e.g., kg/m³ or lb/ft³). This criterion ensures that the vapor flow does not overwhelm the baffle’s ability to promote droplet settling, maintaining efficient separation. Another type of splash baffle is like what is shown in Figure 2. In this configuration, the splash plate is welded to form a triangular side profile. These plates are perforated, allowing vapor to pass through while separating liquid droplets, which fall into the fluid pool below. This design enhances separation efficiency by leveraging both gravity and the perforated structure to capture liquid, making it suitable for applications requiring robust bulk liquid disengagement.

Advantages of splash baffles:

- Simple and cost-effective: Splash baffles require no additional mechanical components, making them an economical choice for basic entrainment reduction.

- Minimal pressure drop: Unlike demisters, splash baffles introduce negligible resistance to vapor flow, ideal for systems sensitive to pressure variations.

- Effective for bulk liquid separation: They excel at capturing larger droplets, improving overall separation efficiency in heat exchangers.

Challenges of splash baffles:

- Placement sensitivity: Improper positioning can restrict flow or reduce effectiveness, requiring careful design to avoid interference with the tube bundle.

- Potential fouling: Poorly designed baffles may accumulate debris over time, necessitating periodic maintenance.

- Limited fine droplet capture: Splash baffles are less effective at removing smaller mist particles, which may still escape with the vapor.

Applications

Splash baffles are commonly used in kettle-type heat exchangers in industries such as oil and gas, where bulk liquid separation is sufficient to maintain system performance. Their simplicity makes them suitable for processes prioritizing low cost and minimal pressure drop.

Demisters: Functionality and applications

How demisters work

Demisters, or mist eliminators, are specialized devices installed at the gas outlet of heat exchangers or separators to capture fi ne liquid droplets. They operate through three primary mechanisms:

- Inertial Impaction: Heavier droplets impact and adhere to surfaces (e.g., wires or vanes) due to their momentum.

- Interception: Droplets are captured when they pass close to solid surfaces within the demister.

- Brownian Diffusion: Very small droplets (<1 micron) are removed through random motion, though this is less significant in industrial settings.

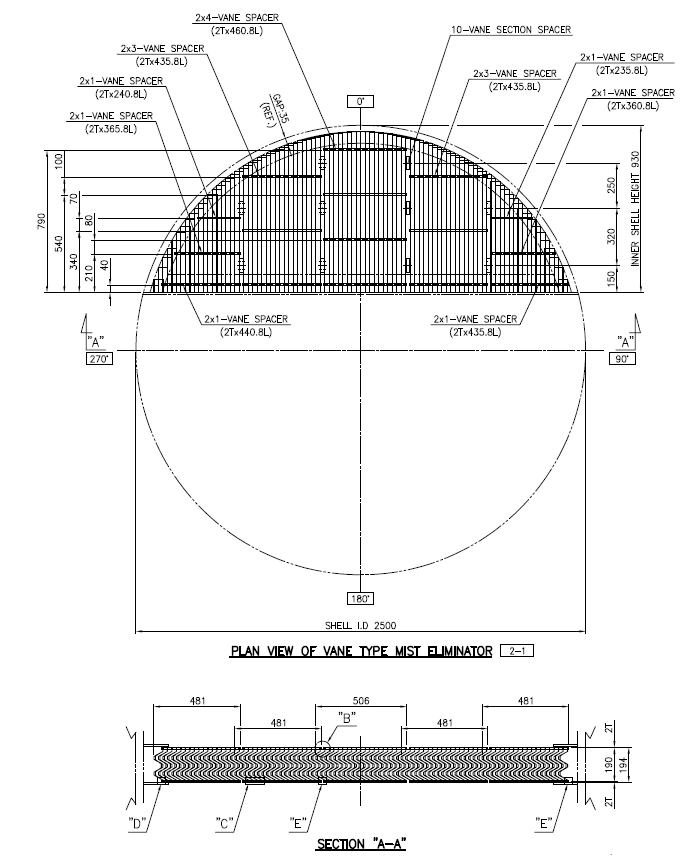

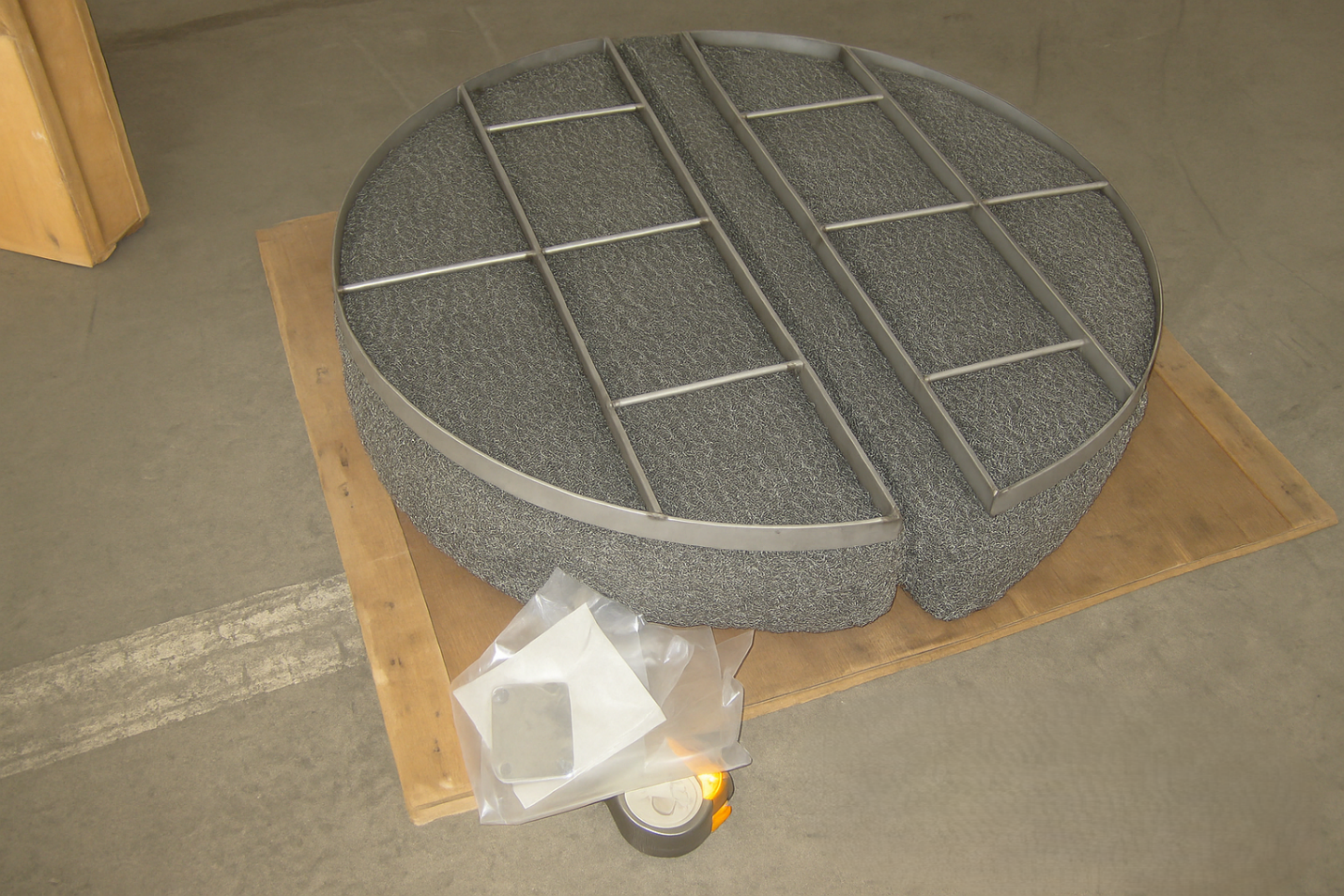

Captured droplets coalesce into larger drops, which drain back into the liquid phase due to gravity. Demisters are typically constructed as wire mesh pads, vane-type separators, or fiber beds, each suited to specific droplet sizes and process conditions.

Types of demisters:

- Wire mesh demisters: Made of knitted stainless steel or plastic, these are cost-effective and suitable for droplets larger than 5 microns. They offer low pressure drop and are widely used in chemical processing.

- Vane-type demisters: Featuring parallel plates with zigzag paths, these are ideal for larger droplets (>8–10 microns) and high-capacity operations, particularly in fouling-prone services.

- Fiber bed demisters: Composed of densely packed fibers, these capture very fi ne mists (0.1–3 microns) and are used in aerosol collection and pollution control.

Advantages of demisters:

capturing fine liquid droplets to ensure high vapor purity.

- High separation efficiency: Demisters excel at capturing fi ne droplets, ensuring high vapor purity for stringent applications.

- Versatile applications: They are used across industries, including petrochemicals, refining, and air pollution control, for processes requiring minimal liquid carryover.

- Robust design options: Different types cater to diverse droplet sizes and operating conditions, offering flexibility in system design.

Challenges of demisters:

- Pressure drop: The resistance to vapor flow can reduce system efficiency, particularly in high-velocity applications.

- Maintenance needs: Mesh-type demisters require regular cleaning or replacement to prevent clogging, especially in fouling-prone environments.

- Higher initial cost: Compared to splash baffles, demisters involve more complex designs and materials, increasing upfront costs.

Applications

Demisters are indispensable in chemical plants for recovering valuable solvents, preventing downstream contamination, and controlling emissions. They are also used in refining of hydrocarbon separation, in food processing for steam stripping, and in environmental applications for capturing acid or oil mists.

Comparative analysis: Splash baffles vs. demisters

Design and operation

Splash baffles rely on turbulence and gravity to separate larger droplets within the heat exchanger, making them a passive, low-maintenance solution. Demisters, positioned at the outlet, use structured surfaces to capture fi ne droplets through impaction and interception, offering superior separation but requiring more complex designs.

Performance:

- Droplet size: Splash baffles are effective for bulk liquid separation but struggle with fi ne mists. Demisters, particularly fiber bed types, can capture droplets as small as 0.1 microns, making them ideal for high-purity requirements.

- Efficiency: Demisters achieve higher separation efficiency, especially in applications demanding minimal entrainment. Splash baffles provide adequate performance for less stringent processes.

- Pressure drop: Splash baffles introduce negligible pressure drop, while demisters, particularly mesh types, can increase resistance, impacting energy

efficiency.

Cost and maintenance

Splash baffles are cheaper to install and maintain due to their simplicity. Demisters, while more expensive upfront, offer long-term benefits in applications requiring high efficiency. However, their maintenance needs (e.g., cleaning mesh pads) can increase operational costs.

Selection criteria

Choosing between splash baffles and demisters depends on system priorities:

- For minimal pressure drop and cost: Splash baffles are preferable in heat exchangers where bulk separation is sufficient.

- For high-efficiency mist removal: Demisters are the better choice for applications requiring fine droplet capture, such as chemical processing or pollution control.

- For comprehensive separation: Combining splash baffles (for bulk liquid) and demisters (for fine mist) can optimize performance in complex systems.

Key design considerations include droplet size distribution, gas velocity (typically 1–4 m/s for demisters), material compatibility, and fouling risks. Engineers must also balance pressure drop against separation efficiency to meet process goals.

Industry perspectives

In heat exchanger applications, splash baffles are favored for their simplicity and effectiveness in kettle-type designs, particularly in oil and gas processing. However, industries like petrochemicals and refining often prefer demisters for their ability to ensure high vapor purity, critical for downstream processes. In chemical plants, demisters are standard in separators to recover solvents and prevent contamination. The choice ultimately hinges on process constraints, maintenance capabilities, and efficiency requirements.

Conclusion

Splash baffles and demisters play complementary roles in vapor-liquid separation, each addressing specific needs in heat exchangers and chemical engineering systems. Splash baffles offer a cost-effective, low-maintenance solution for bulk liquid separation, ideal for simpler heat exchanger designs. Demisters provide superior efficiency for fine droplet capture, making them essential in high-purity applications across industries. By carefully evaluating drop tolerance, and maintenance feasibility—engineers can select or combine these technologies to optimize performance, enhance process reliability, and reduce operational costs.

About the author

Ali Dehghani is a Junior Mechanical Engineer with expertise in the design and analysis of heat exchangers. He holds a master’s degree in mechanical engineering with a focus on thermal management of small satellites using phase change materials, heat pipes, and Nano fluids. Ali has over three years of industry experience and is currently working at EIED (Energy Industries Engineering and Design). He has contributed to several projects involving passive thermal control and advanced heat transfer systems. He can be reached at ali.dehghani1372@gmail.com.

About the co-author

Sara Kafashian is a Senior Mechanical Engineer with nearly 17 years of experience in the oil, gas and energy industries, specializing in heat transfer and thermal systems. My work focuses on design, optimization, and performance analysis of heat exchangers across various industrial applications. With hands-on expertise in engineering and project management, I am passionate about advancing efficient, innovative, and sustainable thermal solutions.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in July 2025. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.