The main Heatric PCHE manufacturing facility in Poole, UK. The Heatric Poole site is a 20,000m2 facility dedicated to bonding, fabricating and testing Heatric PCHEs.

In the push to deliver greater energy efficiency, supercritical CO2 is now emerging as an alternative to steam in power generation. Key to turning the concept into a successful industrial technology are unique printed circuit heat exchangers which are helping to enable its success.

By Renaud Le Pierres, Heatric Business Development Engineer, and Shaun Askew-Jones, Marketing Manager, Filtration & Energy Solutions Division, Parker Hannifin Filtration Group

For more than 140 years, steam has been the working fluid of choice for thermal power generation cycles. In the drive for ever greater efficiencies, alternatives to steam are being developed, with one promising choice now being supercritical carbon dioxide (sCO2). The physical properties of supercritical CO2 being a gas with very high power-density make it an attractive solution, particularly in the increasing desire to deploy smaller, distributed power plants.

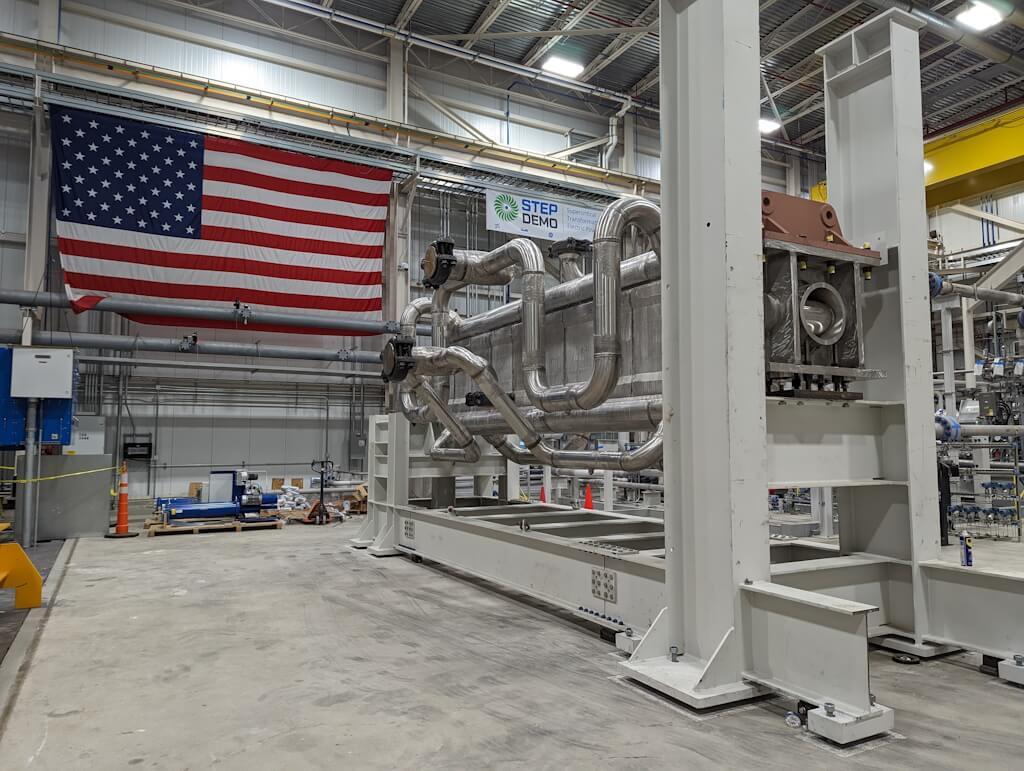

In an exciting breakthrough on the journey to more efficient power generation, a pilot project recently began operations in San Antonio, Texas. The Supercritical Transformational Electric Power (STEP) Demo project aims to prove an indirect-fired supercritical CO2 Brayton cycle concept with a $169 million demonstration plant led by GTI Energy and underway at the Southwest Research Institute (SwRI). The process has completed the first phase of testing, having generated electricity at around 4 MWe while also being synchronised to the grid. However, the journey to reach this milestone meant achieving technical breakthroughs with many key components – including the high temperature heat exchangers.

Supercritical CO2

While the steam cycle has dominated power generation for modern history, CO2 in a supercritical state, has advantageous physical properties that make it behave close to a liquid – allowing the compressor to act closer to a pump – but has the characteristics of a gas in terms of its thermodynamics offering advantages over steam. The benefits of sCO2 power systems include higher efficiencies, reduced emissions from less fuel use, compact turbomachinery, reduced plant size, rapid response to load transients, reduced water use, heat source application flexibility, and overall better potential economics. Given these potential benefits, the use of supercritical carbon dioxide was recognised and first explored in the 1950s. However, limitations in materials and equipment, including the shell and tube heat exchangers in use at the time, curbed the thermal performance and stalled its development.

Decades later in 1985, the printed circuit heat exchanger (PCHE) was developed which enabled compact, efficient, and cost-effective heat transfer at the higher temperatures and pressures associated with sCO2 cycles. PCHE’s consist of flat metal plates in which fluid flow channels are chemically etched. The etched plates are stacked with plates of alternating hot and cold flow channels and are diffusion bonded together to make a strong heat exchanger block with a large heat transfer surface area. Initially, while PCHE’s had helped to enable the use of supercritical carbon dioxide in power conversion cycles experiments, it was still limited to a relatively small scale ranging from a few kilowatts to a few hundred of kilowatts. For targeted industrial-scale applications, something on the megawatt scale was required, and when the PCHE technology became available and proven at commercial scales in O&G it supported cost effective sCO2-based power plants and contributed to the decision to proceed with the 10 MWe STEP Demo project.

STEP into the future

In 2015, under a US Department of Energy/National Energy Technology Laboratory programme, a cooperative grant funding solicitation was issued to design, build and operate a 10 MWe supercritical carbon dioxide demonstration loop – the STEP Demo project (www.STEPdemo.us). The project was won by GTI Energy, a technology development and training organization, who became project lead working in partnership with GE Vernova, and fellow non-profit organisation SwRI, along with power cycle specialists including Heatric and others. Fundamental to the power cycle is the need for large amounts of heat recuperation and among the key components for the STEP Demo project are three high efficiency heat exchangers based on PCHE technology. These exchangers are the High Temperature Recuperator (HTR), the Low Temperature Recuperator (LTR), and the Main Cooler (MC). Heatric won the contract for the design, engineering, manufacturing, and supply of all three heat exchangers in August 2018.

In terms of design, the MC is a relatively conventional PCHE similar to those widely used and well-proven in the oil and gas industry over many decades. The LTR design is slightly more customised for the duty but still close to conventional PCHEs in its layout, whilst the HTR is a heavily customised PCHE to manage more aggressive process conditions while still using regular austenitic stainless steel. This HTR design led to many collaborative work activities and iterations between GTI Energy, SwRI and Heatric to facilitate its integration within the STEP Demo process loop. Design conditions for the main cooler are 150 °C temperature and 175 barg pressure. For the low temperature recuperator, design conditions are higher than those found in the MC at 290 bar and 250 °C, although still easily managed by conventional PCHE technology. However, for the high temperature recuperator, a design temperature of 600 °C and pressures of the order of 290 bar make for much more challenging conditions that had to be addressed and required some design changes for the plant even post-contract.

The difficulty of this sCO2 cycle is the combination of high pressure and high temperature; and whilst that is advantageous from a thermodynamic point of view, it is a major challenge from a thermal-mechanical design point of view. To manage this high-temperature and high-pressure CO2, the necessary pipework needed to use thick walls leading to very high thermal stress / loads on the recuperator as the thermal expansion of thick sections can deliver substantial mechanical forces. The design of the pipework to bring the working fluid into and out of the heat exchangers and turbines thus became a complex problem.

Secondly, a fully bonded and fully welded compact heat exchanger with a large heat gradient results in high bending stresses. This thermal expansion issue presented substantial engineering challenges that had to be overcome.

A collaborative road to project success

Heatric had worked with several of the partner organisations in the design of the thermal loop and to establish equipment sizing considerations even prior to the STEP Demo project’s call for suppliers of equipment. Subsequently, during the detailed design and implementation phases, collaborative working practices between Heatric, SwRI and GTI Energy were critical to addressing these challenges. This was despite the impact of COVID restrictions, which limited the opportunities for face-to-face discussions and work. The site was still being built, and the main equipment was in the delivery phase when the COVID global pandemic hit, which slowed down the project tremendously.

Ultimately, though, the collaborative relationship was key to the success of this unique project. As a first-of-a-kind development, it is only when physical development starts that some of the issues that may not have been known or identified during the project definition stage emerged. It is at these most challenging times that the relationship is most important to be able to address those issues constructively. Sadly, many first-of-a-kind projects have historically failed and fallen by the wayside as they got closer to execution, but the foundation of a solid collaborative relationship between Heatric, GTI Energy and SwRI was there to help overcome these difficulties.

The HTR was delivered in 2021, with electricity first produced mid-2024 and subsequently tested successfully in a simple cycle configuration, using the HTR and the main cooler and generating some 4 MWe net in late 2024.

John Marion, Senior Director for Carbon Management & Conversion at GTI Energy, summarises the importance of the project success. “We are delighted with the project achievements to date. The STEP Demo facility is a driving force in power cycle technology development, establishing the groundwork for future sCO2 applications. GTI Energy is proud to be leading this collaboration enabling future low carbon power generation processes.”

Commenting on the project, Dr. Tim Allison, director of SwRI’s Machinery Department, highlighted the pioneering nature of the technology and the role of close collaboration in achieving this remarkable energy sector breakthrough. “The success of phase 1 of STEP Demo is a major advancement of the commercial maturity of these transformative power systems which represents many technical firsts. Overcoming the challenges associated with the combination of operating temperatures and pressures while generating power highlights the tenacity and perseverance of STEP Demo’s engineering and project teams,” said Dr. Allison.

The sCO2 opportunity

The characteristics of sCO2 offer around a 10% increase in efficiency when compared with conventional steam cycles. This is a substantial advantage over existing steam cycle approaches. In addition, though, the use of sCO2 allows a far more compact power block to be deployed. The turbomachinery components in the STEP Demo project are approximately one-tenth the size of a conventional steam power plant. The turbine has a diameter of about 18 cm, for example, while the heat exchangers are also far more compact than conventional shell and tube type designs. This not only reduces the footprint, the environmental impact and construction cost of a new generation asset but also favours the deployment of sCO2 in multiple retrofit applications. Once installed, simple cycle gas turbine power plants typically face severe restrictions on the available space that would rule out the subsequent addition of a steam cycle. The compact footprint of the sCO2 power conversion island alleviates that issue, making it well suited for use with aero derivative gas turbines such as the LM2500 from GE, for example. There is also scope for installing these devices aboard offshore oil and gas platforms, which typically use simple cycle gas turbines. Both these applications – converting a simple cycle machine into a sCO2 combined cycle – creates a very high efficiency yet compact unit, making operations more efficient and burning less gas.

Furthermore, the sCO2 Brayton cycle device can be applied to many different heat sources, including concentrated solar power, advanced nuclear reactors, industrial waste heat, thermal energy storage and geothermal heat.

The next STEP

Currently, GTI Energy, SwRI, and GE Vernova are reconfiguring the STEP Demo pilot from a simple cycle to a Recompression Closed Brayton Cycle (RCBC) system configuration. This advancement will allow the installation to reach higher efficiencies for the overall loop by including the LTR. In this second phase that is taking place this year, the project will further increase the operating temperature to 715 °C, raise the output to the full 10 MWe net, and increase net plant efficiency.

The project is hailed as a success story having generated electricity and is operating as expected. With a design rating of 10 MWe net, STEP Demo is the largest such facility to be operational in the world. Having proven its ability to meet initial performance targets, including its full operational turbine speed of 27,000 rpm and achievement of the initial target turbine inlet temperature of 500 °C, the STEP Demo project marks a critical shift in the technology’s development and puts it on a firm footing for future commercialisation. It might even be said that STEP is a supercritical breakthrough for energy.

About the authors

Renaud Le Pierres is responsible for assisting in the development of Heatric (Parker Filtration and Energy Systems) business within new markets, with specific focus on power generation, energy storage, carbon capture, and waste heat recovery applications. Since joining Heatric in 2005 as a design engineer in the nuclear department, Renaud has been involved in various new power conversion cycles and has been involved in many advanced gas power conversion cycles and energy storage projects.

Renaud Le Pierres is responsible for assisting in the development of Heatric (Parker Filtration and Energy Systems) business within new markets, with specific focus on power generation, energy storage, carbon capture, and waste heat recovery applications. Since joining Heatric in 2005 as a design engineer in the nuclear department, Renaud has been involved in various new power conversion cycles and has been involved in many advanced gas power conversion cycles and energy storage projects.

Shaun Askew-Jones is the Marketing Manager at Filtration & Energy Solutions Division, Filtration Group, Parker Hannifin Corporation.

Shaun Askew-Jones is the Marketing Manager at Filtration & Energy Solutions Division, Filtration Group, Parker Hannifin Corporation.

Shaun started his marketing career as a Marketing Analyst at Heatric in 2018, rising to Marketing Manager in 2020. Since 2024, Shaun has overseen marketing activities for all brands and products within the new Filtration & Energy Solutions Division within Parker Hannifin, covering heat exchanger and air inlet filtration product lines.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.