Text and images courtesy of Mersen

Tantalum is the most corrosion-resistant metal in common use today. It is inert to practically all organic and inorganic compounds, with a corrosion resistance very similar to glass. Tantalum is often used for the manufacture of dip tubes, piping and overhead condensers.

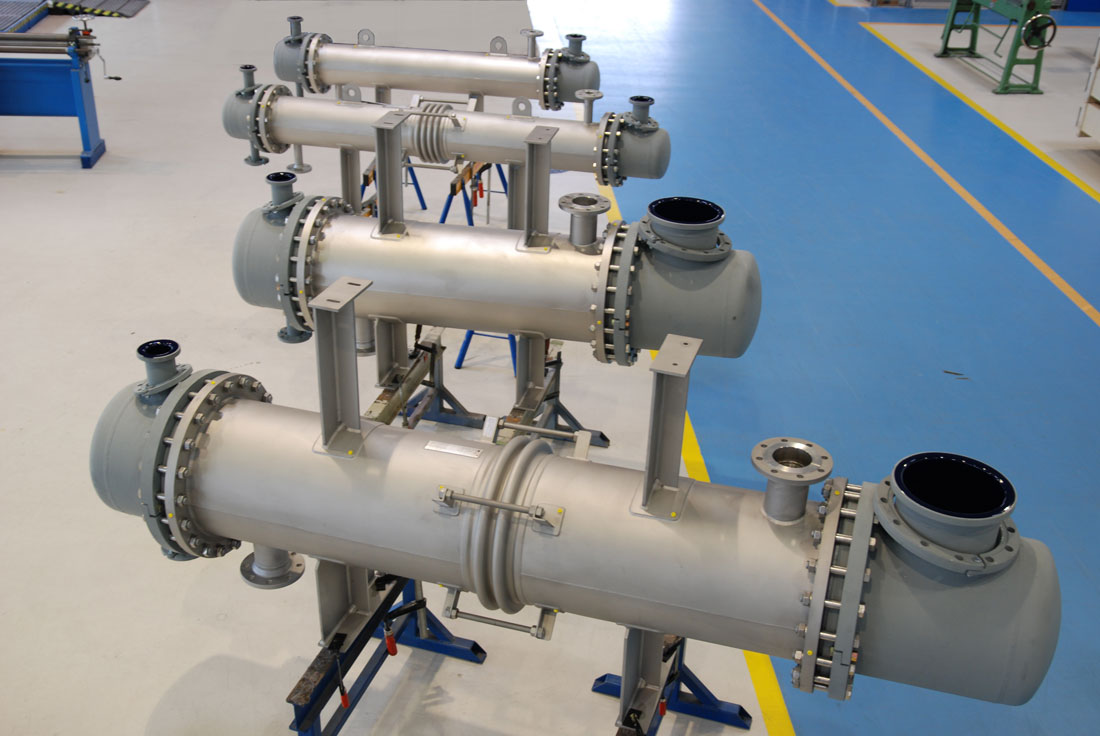

Applications of Tantalum should be considered wherever corrosion is a factor and where long-term benefits such as reduced downtime, increased life expectancy and profitability are important. Tantalum heat exchangers are used in ultra-corrosive and oxidizing applications, for example with concentrated sulfuric acid, nitric acid, free chlorine, or free bromine. They are also widely used as vapor condensers in multipurpose fine chemical and pharmaceutical applications. Mersen Linsengericht, near Frankfurt Germany, is a center of competence dedicated to the design and manufacturing of tantalum process equipment such as heat exchangers, pressure vessels, columns, and custom-made parts. The company’s 3200 m² workshop enables the production of very large pieces of tantalum equipment (up to 4.4 meters in width and up to 4.2 meters in height, with a maximum weight of 20 tons).