In modern industrial plants, energy efficiency has shifted from a secondary consideration to a core operational imperative. Across refining, petrochemical, and chemical processing, the drive to reduce energy consumption and emissions has placed heat recovery and waste heat reclamation at the forefront of engineering strategies. While discussions often focus on major equipment like advanced heat exchangers, high-efficiency boilers, and integrated plant networks, one often overlooked factor is the sealing system.

By Iryna Mukha, Heat Exchanger World

TEADIT® is uniquely positioned as a global sealing manufacturer with a complete portfolio of gasket technologies to address critical pain points experienced in these high-profile applications. Its range of engineered solutions enables TEADIT® to use effective sealing to optimize industrial energy efficiency by maximizing uptime, minimizing emissions, and extending the life of heat recovery assets.

The Intersection of Heat Recovery and Sealing Performance

Whether in refinery heaters, waste heat boilers, or combined heat and power (CHP) systems, energy is only as valuable as the system’s ability to capture and retain it. Industrial waste heat is the result of energy produced during industrial processes that is not utilized, as it is lost through exhaust gases, hot products, or heated equipment. Studies estimate 20–50% of industrial energy becomes waste heat. While some losses are unavoidable, facilities can reduce them by improving efficiency with engineered technologies.1

Gaskets directly affect the reliability, safety, and efficiency of heat exchangers and related equipment. Leaks, pressure drops, and fugitive emissions diminish system gains. Selecting the right gasket material is, therefore, a strategic decision with operational and environmental implications.

The value of a gasket

A gasket’s role is deceptively simple: maintain a tight seal under fluctuating pressures, thermal cycling, and chemical exposure. Achieving this requires materials that withstand creep, vibration, and process media without degradation, aligned with a plant’s operating conditions, maintenance strategy, and compliance goals.

Waste heat applications are particularly demanding. High temperatures accelerate creep and relaxation, reducing gasket stress and leading to leakage. Pressure fluctuations, thermal expansion, and corrosive condensates compound these issues. Here, TEADIT®’s breadth of materials provides critical value.

TEADIT® gasket materials for energy optimization

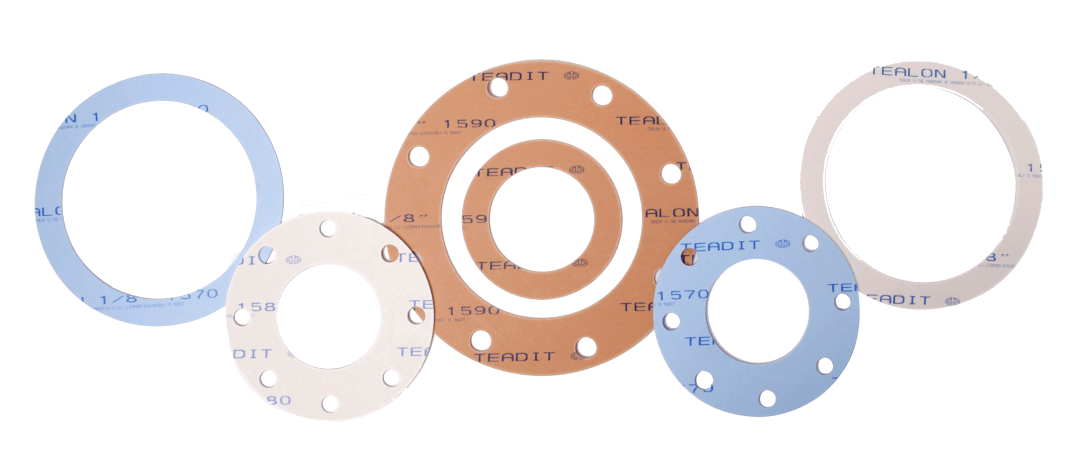

1. Expanded PTFE (ePTFE)

Ideal for low-torque applications where chemical resistance and conformability matter. ePTFE adapts to flange irregularities, sealing corroded faces or uneven surfaces with minimal leakage. In condensate recovery and low-pressure exchangers, it delivers reliable performance with negligible cold flow when installed correctly.

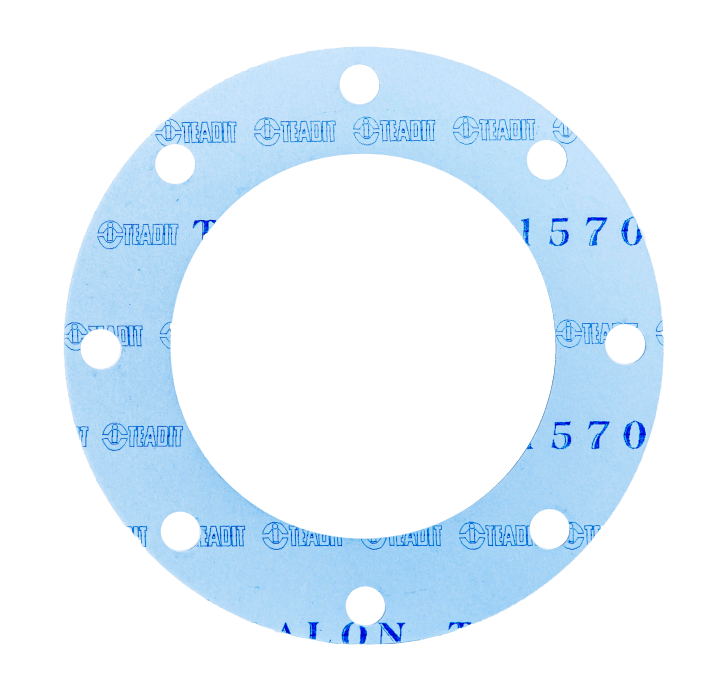

2. Restructured PTFE (rPTFE)

Tealon® sheets offer superior creep resistance and mechanical stability under fluctuating temperatures. Available in multiple styles, rPTFE balances conformability, recovery, and sealability without sacrificing chemical compatibility, ideal for waste heat exchangers under thermal cycling.

3. Compressed Fiber Sheets

Blending elastomeric binders with aramid or inorganic fibers, these sheets withstand moderate to high pressures and temperatures. They provide reliable sealing in economizers, air preheaters, and auxiliary exchangers, with excellent blowout resistance and stability.

4. Flexible Graphite Sheets

Essential in high-temperature applications with steam, hydrocarbons, or oxidizing gases. TEADIT® graphite gaskets maintain seal integrity under cycling conditions, resist creep relaxation, and handle temperatures beyond most gasket materials, making them indispensable in boilers and ducting. For demanding services in oxidizing environments, TEADIT® also offers oxidation-inhibited graphite, extending service life where conventional graphite would otherwise degrade.

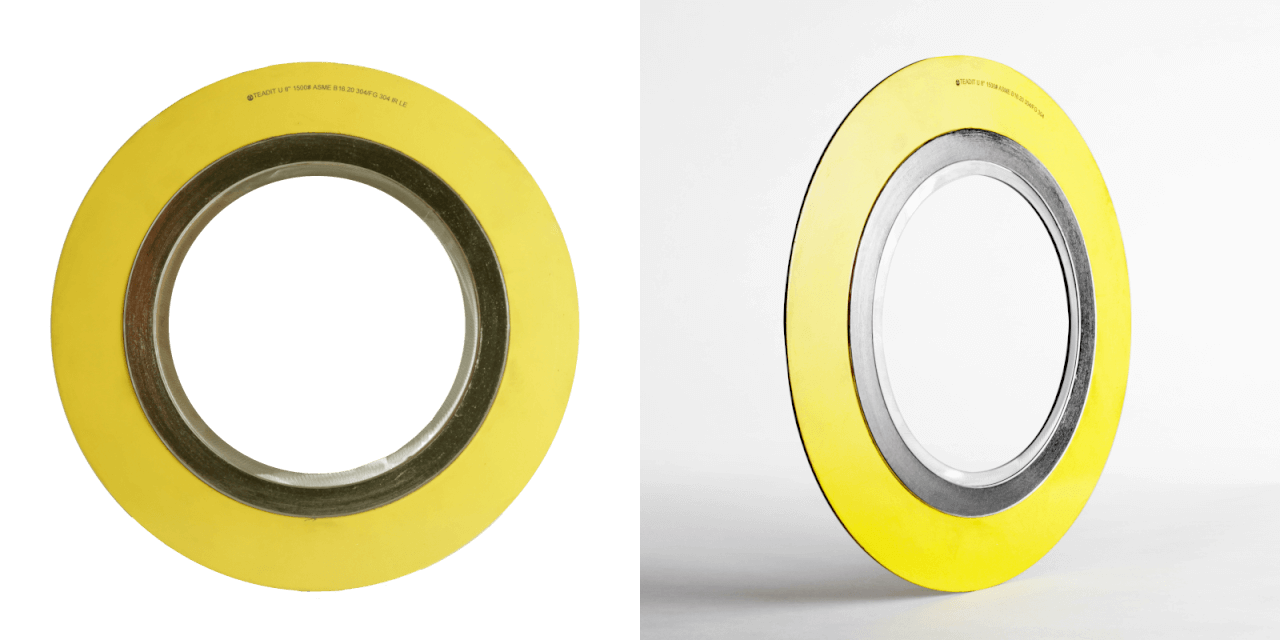

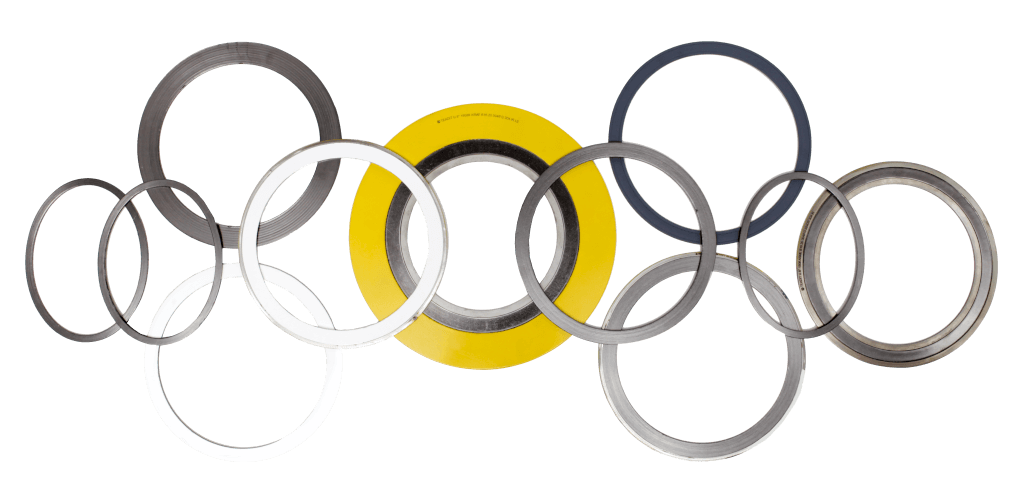

5. Metallic & Semi-Metallic Gaskets

For extreme pressures and temperatures, TEADIT® spiral wound, corrugated, jacketed, and kammprofile gaskets combine metal strength with soft material sealability. Used in large exchangers, heaters, and waste heat boilers, they resist vibration, flange rotation, and thermal expansion.

Sealing and energy efficiency: A direct correlation

Energy loss is not always visible. Micro-leakage or pressure decay across flanges reduces thermal efficiency, forcing plants to burn more fuel or run auxiliary systems harder. This raises costs and emissions.

Deploying gasket solutions tailored to each service yields measurable gains:

- Improved thermal efficiency by eliminating leakage paths.

- Reduced downtime through longer maintenance intervals.

- Lower emissions via reduced fugitive leakage.

- Increased safety by preventing hazardous leaks.

When gaskets are treated as commodities, energy recovery projects can fall short. Addressing this with engineered material selection, application support, and testing to validate performance under real-world conditions is a viable solution for energy conservation.

Case study: Waste heat recovery in a petrochemical plant

A Gulf Coast petrochemical facility sought to expand its waste heat recovery network, expecting 5–7% fuel savings. Early commissioning revealed flange leakage, particularly in units exposed to thermal cycling.

A TEADIT® survey found non-optimized gasket materials lacking creep resistance and recovery. The plant adopted a multi-material sealing strategy:

- Spiral wound gaskets with oxidation-inhibited graphite for high-pressure, high-temp headers.

- Tealon® rPTFE sheets for condensate return flanges under frequent cycling.

- ePTFE sheets for corroded or low-bolt-load flanges requiring a highly conformable seal on irregular surfaces.

The result: a leak-free startup, achieved an estimated annual fuel savings of 25,000 MMBtu, and reduced CO2 emissions by over 1,000 metric tons.

The TEADIT® advantage: From material science to operational value

TEADIT®’s broad manufacturing capability enables holistic solutions, unlike suppliers limited to one material type. Supported by API, ASME, and EN testing, TEADIT® offers:

- Tailored solutions across ePTFE, rPTFE, compressed fiber, graphite, metallic, and semi-metallic gaskets.

- Versatility for low-pressure lines to extreme-temperature headers.

- Lifecycle optimization through longer service life and fewer leaks.

- Sustainability with verified low-leakage performance.

TEADIT® also provides engineering support, bolted joint analysis installation training, and post-installation monitoring to ensure long-term sealing reliability.

The silent contributor to a sustainable future

As industry pushes toward net-zero, heat recovery and reclamation remain vital pathways to reduce fuel use and emissions. Success, however, depends not just on major equipment but also on sealing systems that ensure integrity.

A single gasket failure can negate a multi-million-dollar energy investment. A properly selected gasket, by contrast, can operate for years without incident, conserving energy and preventing leaks.

TEADIT® is committed to helping industry realize the full value of heat recovery through diverse materials, engineered solutions, and proven performance, ensuring sustainability is built on reliability at every joint.

References

- Waste Heat Recovery: Technology and Opportunities in U.S. …, www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/waste_heat_recovery.pdf. Accessed 8 Aug. 2025.

- Chemical Engineering. “Waste Heat Recovery Methods and Technologies.” Chemical Engineering, 11 Nov. 2015, www.chemengonline. com/waste-heat-recovery-methods-and-technologies/?printmode=1.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.