Thermo-Clean is equipped to cater to businesses across Europe with its comprehensive “10-step total care heat exchanger cleaning service“ aka Total Cleaning.

For over 35 years, Thermo-Clean Group has been at the forefront of thermal cleaning innovation. Under the leadership of Robert Mol, the company has expanded from a small branch to cover multiple countries, offering cutting-edge, sustainable, and highly efficient cleaning technologies. In this interview, we learnt how with a commitment to continuous improvement and environmental responsibility, Thermo-Clean is setting new industry standards while preparing for future growth.

By Iryna Mukha, Heat Exchanger World

Over 35 years of history

Thermo-Clean originated in 1989 as a branch of Jos Mol Coatings, a Belgium and Luxembourg-based powder coatings distributor. Since 2005, the company has been headed by Robert Mol. Through his relentless efforts spanning over three decades, Mol has successfully turned Thermo-Clean into one of the market leaders in the thermal cleaning industry, boasting 10 branches throughout Europe and sturdy plans for further expansion. “I joined the company in May 1989 as the second employee. It was just us two initially,” shares Robert. “We were propelled by inquiries from our Jos Mol Coatings customers about equipment cleaning and in response, we started Thermo-Clean by primarily serving the paint industry. The effectiveness of our strategies in dealing with other substances such as oil, plastic, and glue became evident later on.” Under Robert’s leadership, the company has transformed into an expert in the fields of thermal heat exchanger cleaning, polymer removal, and filter cleaning. “Our proprietary thermal cleaning technique allows us to restore heat exchangers and parts to their original performance level. This translates into improved heat transfer, diminished energy costs, and a reduced environmental impact as a more efficient heat exchanger results in less fuel consumption and consequently, fewer greenhouse gas emissions.”

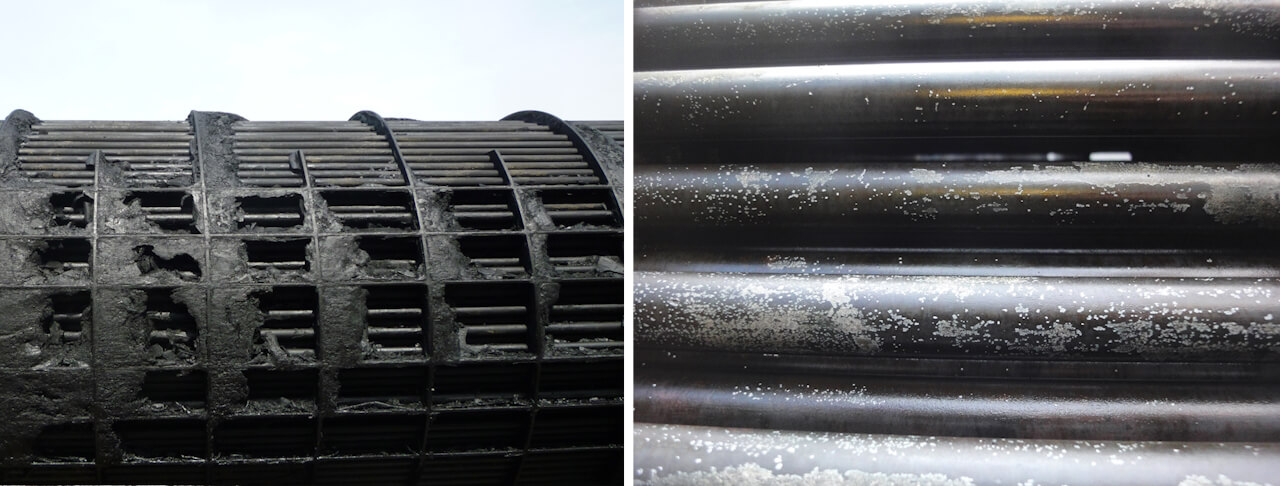

In situations where customers are unsure about the type of fouling affecting their heat exchanger, Thermo-Clean performs a preliminary test using a sample to identify if the fouling is organic, inorganic, or a blend of both. “This test helps us understand the aftermath inside the pyrolysis oven such as by what percentage we can reduce this fouling,” says Robert. “In case of any uncertainties, we conduct a further thermogravimetric analysis (TGA) test to delve into what the fouling comprises.”

The team typically starts the process by understanding the weight, volume, and design of the exchanger to provide a quotation and a detailed cleaning schedule. “Once an agreement is reached, we arrange to collect the exchanger from the customer. The first and foremost task upon arrival is to arrange the appropriate support for the exchanger to prevent buckling or distortion during the cleaning process,” adds Robert. “We then set up thermal components throughout the heat exchanger to monitor the temperature at various parts to ensure uniform heating.”

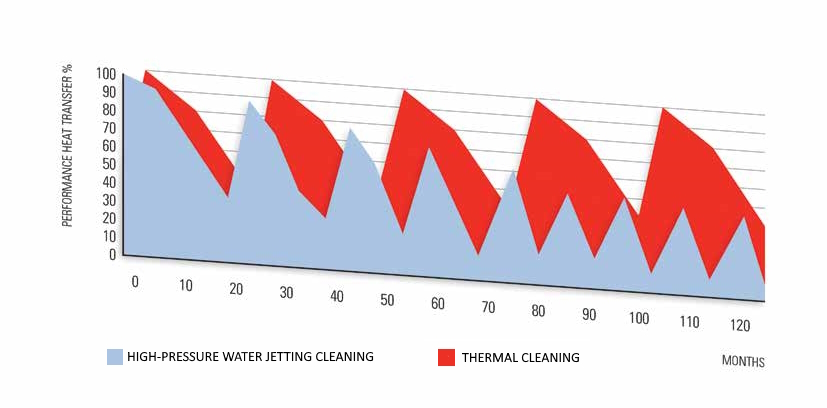

According to Robert, compared to high-pressure methods, Thermo-Clean can pre-calculate the cleaning duration more precisely. “With our technology, we can let the client know beforehand whether 24 hours, 40 hours, or 60 hours are needed for cleaning. This optimizes planning for the client.

In contrast, other methods may take up to 1-2 weeks resulting in lost time and even then, only 70% of the fouling is eliminated,” Robert points out. “In our case, the cleaning duration is primarily dictated by the quantity of fouling and the weight of the part as we need to raise and reduce the temperature gradually to avoid distortion. As the thinner tubes heat up and expand faster than the thicker plates, we need to ensure uniform expansion and contraction.”

Unique solutions

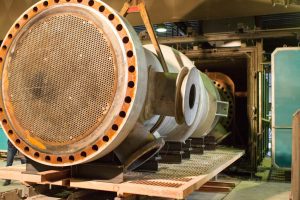

There are numerous businesses offering thermal cleaning, but Thermo-Clean raises the bar with their tailor-made solutions for cleaning large and heavily tainted parts. “Our cleaning/pyrolysis ovens, exclusively designed for Thermo-Clean, are the result of a partnership with an in-house system provider,” shares Robert. “They are unique in the market because we also develop our own software to operate these cleaning machines. This approach enables us to cleanse specialized heat exchangers and restore their performance to an unmatched level.”

Their collaboration with TC Machinery BV has led to the development of an apparatus offering an efficient and secure environment for the superior thermal cleaning of heat exchangers. What makes these ovens exceptional is the ability to regulate oxygen and temperature, allowing accurate monitoring of the gasification of organic fouling during the cleaning process. Additionally, the company’s large-scale units can handle multiple exchangers at once, assuming they share the same specifications, size, weight, and fouling type.

More than just cleaning

With its presence in the Netherlands, Belgium, France, Germany, and Slovakia, Thermo-Clean is equipped to cater to businesses across Europe with its comprehensive “10-step total care heat exchanger cleaning service “ aka Total Cleaning.

Total Cleaning is the foundation of Thermo-Clean’s approach to heat exchanger maintenance, ensuring maximum efficiency, reliability, and longevity. Traditional cleaning methods, such as water jetting and chemical washing, fail to deliver a truly comprehensive clean. These methods remove only superficial dirt, leaving behind persistent fouling that compromises performance and energy efficiency. Thermo-Clean’s advanced thermal cleaning technology, however, offers a complete solution that restores heat exchangers to their original state.

The process begins with the placement of the heat exchanger into a specialized oven where temperatures gradually rise to 420°C in a controlled environment. At this stage, organic contaminants are broken down and converted into gas. These gases are then recovered and used as fuel for the ovens, making the process both environmentally friendly and cost-efficient. What remains of the fouling is reduced to fine dust, which is then rinsed away, leaving behind a heat exchanger that is completely free from historical contamination. This method is effective even in hard-to-reach areas that traditional cleaning techniques cannot access.

The benefits of thermal cleaning extend beyond just cleanliness. A heat exchanger that is 100% clean operates with better throughput, consumes less energy, and enjoys an extended service life. Unlike on-site cleaning, which can be hazardous and environmentally damaging, Thermo-Clean’s process significantly reduces waste and water consumption. Every kilogram of contamination is converted into just 50 grams of ash, and water usage is cut by 95% compared to conventional methods.

“But Total Cleaning is not just about the cleaning itself,” begins Robert “it’s a fully managed process designed to unburden the customer from start to finish. We take complete responsibility for transportation, maintenance, and reinstallation, ensuring a seamless experience. Additionally, with this method, we were able to achieve minimal downtime by cleaning not only the entire heat exchanger, but also its shell. ” Their structured 10-step process guarantees efficiency and reliability at every stage:

- The customer removes the complete heat exchanger and its shell for transport.

- Thermo-Clean arranges secure transportation to the nearest specialized facility.

- The unit is carefully disassembled, including removal of heads and floating heads.

- If necessary, a preliminary cleaning is performed to safely extract the heat exchanger from its casing.

- The thermal cleaning process is executed in in-house developed pyrolysis ovens, followed by high-pressure water jetting to remove remaining residues.

- Additional maintenance is conducted, such as casing refinishing, eddy current testing, and tube repair or replacement if needed.

- The heat exchanger is fully reassembled.

- Multiple pressure tests are performed to ensure the unit is 100% operational and free from leaks.

- The cleaned and tested heat exchanger is prepared for shipment.

- The unit is returned to the customer, ready for immediate installation and use.

This comprehensive approach ensures that customers receive a heat exchanger that performs at peak efficiency, reducing operational costs and preventing unexpected downtime. Thermo-Clean’s Total Cleaning service is not just a cleaning process; it is a commitment to delivering superior performance, sustainability, and peace of mind. Whether in industries like power generation, chemical processing, or food production, Thermo-Clean provides a turnkey solution that eliminates hassle and maximizes results. For those seeking a truly clean, fully optimized heat exchanger, Total Cleaning by Thermo-Clean is the ultimate choice.

Hand in hand with the future

Thermo-Clean is also marking its stand in sustainability, proving that innovation and eco-consciousness can go hand in hand. At the heart of their strategy is a strong commitment to mitigate climate change by aggressively curbing emissions generated from their operations.

The focus is on reducing pollution from their ovens, an initiative which involves a dedicated exploration of new technologies. This can ensure the preservation of their service quality while reducing their carbon footprint. The vision is clear: deliver supreme cleaning results with fewer emissions.

To further help customers understand the importance of adopting sustainable practices, Thermo-Clean has partnered with an expert company to construct a computation tool for customers. This tool serves to compare and contrast traditional cleaning methods with thermal technology, but through the lens of CO2 emissions. It’s an enlightening look into the environmental implications of our everyday choices.

“We believe that superior cleaning results can spark a chain reaction leading to reduced energy consumption in customers’ factories. It’s a win-win situation – superior cleaning results bring about a cleaner environment, both at the level of the individual factories and the planet as a whole,” explains Robert. Sustainability isn’t just a buzzword for Thermo-Clean, rather it is woven into every aspect of their work and service. They are committed to doing their part in the global fight against climate change and are helping their customers do the same through their services.

Looking ahead

With a vision set for the future, Thermo-Clean is not just enhancing its operational capacity, but also planning on widening its geographical reach. The company has been actively preparing other Thermo-Clean sites with the same equipment, with a special emphasis on developing a dedicated cleaning team to cater to industries with specific cleaning needs, such as heat exchangers in the chemical and petrochemical industry. Recent attention has turned towards potential expansion into regions like Saudi Arabia and potentially North America. Demand for Thermo-Clean’s unique services is growing in these locations, however, challenging market conditions have currently curtailed these plans. And yet, Robert Mol remains optimistic, stating that they aim to establish one or two factories in those regions within the next five years.

Robert expresses confidence and optimism when discussing the company’s future plans and focus, stating, “I really hope within five years that we can be active in one or two of the regions I’ve mentioned because I really think that there are big opportunities for us.” It’s clear that Thermo-Clean is on an exciting path of expansion and innovation, all while prioritizing their commitment to sustainability and customer needs.

About this Featured Story

Why Subscribe?

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.