Image source: Dreamstime

At Sterling TT, we wanted to have top-class environmental management systems in place. To make this happen, we sought certification for ISO 14001, the international standard for effective environmental management systems.

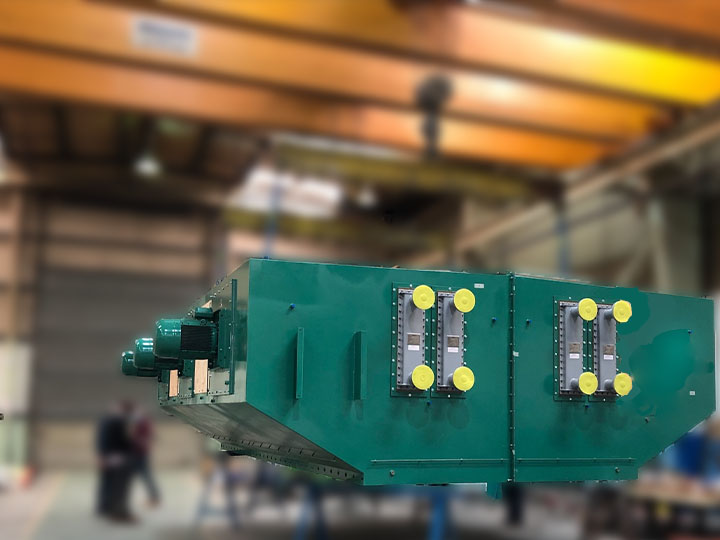

Following text and images courtesy of Sterling Thermal Technology

We are fortunate that our top management is committed to improving Sterling TT’s environmental performance. Our CEO, Emrah Gozturk, listed environment management at the top of his priorities in an interview with British Manufacturing Podcast. Getting our company ISO 14001 certified is part of his wish “to leave our children a better world.” He does not only want to “help our customers to reduce their impact on the environment”; he also wants our company and employees to do so.

Lee Hatton, our Quality & Environmental Officer, has spearheaded this recent push. When Lee started at Sterling TT, there were some actions to protect the environment but no formal environmental management system in place. So, in today’s world, where reducing environmental impact is crucial, we recognised our existing approach left a lot of room for improvement.

With the will to become a leader in eco-friendly heat exchanger manufacturing practices, Sterling TT has made exciting improvements in the last 12 months. This article explains the changes we made to comply with the standard, and the benefits we saw as a result.

What is ISO 14001?

ISO 14001 is an internationally recognised standard that maps out a framework for companies to set up an effective environmental management system (EMS). It helps meet environmental regulations and improve efficiency and environmental performance.

Being ISO 14001 certified demonstrates an ongoing commitment to improving environmental performance, such as reducing waste, saving energy, and minimising carbon footprint.

Each industry and company is different and the actions they can and should take also are. Therefore, ISO 14001 is not about meeting specific targets or taking particular actions.

You must have an effective framework in place for compliance and improvement. The structure of the standard is based on the cycle of the “Plan-Do-Check-Act” approach and includes clauses about leadership, documentation, and performance evaluation.

Areas of improvement for Sterling TT

Waste management

For us, one priority was waste management. As a manufacturing company, there will always be some quantity of raw materials that end up as waste, and processes that have the potential to create hazardous by-products, such as effluent. These can harm the environment if not controlled and disposed of properly. To minimise our impact, we asked ourselves questions about our waste streams, such as:

• Where does our waste end up?

• Is it being disposed of correctly?

• Are the companies we are using registered waste handlers?

• Once it goes to them, how are they disposing of it?

“It was quite interesting to find out where our waste ends up. The companies that we currently use are good. There’s nothing to landfill whatsoever. So, we’re 100% on landfill diversion.” Lee Hatton, Quality & Environmental Officer By enhancing our recycling systems, we are contributing to the circular economy.

Energy usage

At Sterling TT, we always look at ways to reduce the amount of energy we use.

In the past, we failed to fully monitor our energy usage, but we’re glad to say that we now do. We can look at where we use energy and where we can reduce its usage. The result is positive: we anticipate a significant energy usage reduction in 2022 compared to 2021.

We are also exploring ways to further improve on our energy use by implementing other energy sources such as solar panels, combined heat and power systems, battery storage, and voltage optimisation. We are also looking at updating machinery and equipment for more energy-efficient ones.

We’re willing to investigate everything, whether it is a significant trendy change like installing solar panels or a mundane but effective one like replacing windows. A lot of heat can be lost from low-quality windows. If they haven’t been replaced for a long time, it’s an excellent opportunity to save energy.

Supply chain

The locations of our suppliers make a difference. Where possible, we only use UK or European suppliers to reduce the carbon emissions of transporting materials around the globe. We also have started checking our suppliers to see if they are ISO 14001 compliant. By ensuring they are, we know the positive impact on the environment doesn’t stop at Sterling TT.

Heat exchangers

The main way to make a heat exchanger more environmentally friendly is by looking at the lifespan.

• Can we improve heat exchanger designs so that they last longer?

• Can we offer a refurbishment?

• How are these units disposed of?

• Do they contain hazardous material we need to make our customers aware of? Do we offer the best advice on how they dispose of it?

Of course, we already design heat exchangers to last as long as possible, and offer an aftersales service to our customers. But there is never a bad time to ask ourselves how we can make things even better.

Other changes

A thorough investigation of your processes can sometimes inspire changes that aren’t obvious. For example, we discovered that grants are available for offering electric chargers on our premises for employees with electric cars. There is no cost to our employees: they can come and charge their vehicles for free. It gives our staff an incentive to use electric cars. It might also facilitate a future electric car fleet for Sterling TT. We’re always looking ahead.

How we implemented ISO 14001

Starting the certification process

We bought a copy of the ISO 14001 standard and investigated what we needed to do as a company to be certified. Then we selected TUV, a large and well-recognised certification body, to help go through the process. This part of the journey started with a pre-audit.

Engaging the company

A top-down approach is vital when it comes to significant company changes. We needed engagement from the management team to ensure they could provide support. With our management on-side, we worked from top to bottom. We organised training, monthly meetings and communication boards for the production members. We looked at systems at every manufacturing stage, from pre-production to after-production/post-production.

When new processes and procedures are in place, they must be filtered down to the shop floor.

Training

To kick off our new environmental management system with our staff, we presented an overview of the environmental fundamentals and how they apply to Sterling TT.

• What environment means

• The impact we could have on the environment

• Why it is beneficial to implement changes

• Why we should be more environmentally friendly

• How we can avoid pollution

• Where we should dispose of our waste

• How we can save energy in the company

Then, we made further training sessions that were more specific to people’s job roles. For example, spill kit training and waste consignment note training. The goal was to make our staff aware of getting the correct documentation when moving hazardous waste.

Every month, we had a meeting in which we discussed anything that had cropped up in the month. We discussed any improvements and gave people a chance to contribute. How could Sterling TT do better? We included every department of the company, from the shop floor to the boardroom, so everyone knew what was happening. The advantage of these meetings was that we pulled in perspectives from across the company. Staff working in these departments could have seen something the environmental officer may have missed.

These meetings also kept all staff engaged and ensured they knew they could make a difference.

In addition, we created monthly notices. They provided data on how much waste we generated, how much energy we used, and even how much scrap metal we produced. That way, everyone knew where the company stood compared to its targets.

An ongoing process

ISO 14001 certification isn’t a one-and-done situation. TUV will now come in once a year to audit our Environmental Management System to ensure we still comply with the standard. That means continuing and improving our actions, training, and understanding legal requirements. Are there any new legislation, directives or messages from the Environment Agency that we should be aware of and consider? You don’t get complacent when it comes to environmental management.

The challenges we faced

Timescales

Sometimes being too eager can be challenging. It was the case with our original goals for ISO 14001 certification; we wanted it in place within six to nine months. The sheer effort and commitment that had to go into getting it in place in the time frame was quite something, but we managed to achieve it!

Legislation

There are a lot of legislation and regulations to get to grips with. We used the guidance of the Environmental Agency (EA) to help us put a legal register in place and make sense of the law. Still, even then, it was time consuming to determine what legislation was relevant to Sterling TT.

Changing perceptions and habits

As with any successful, long-running company, we are blessed with people who have been here for many years. They bring tremendous experience and institutional knowledge to the table, but some are set in their ways; they have been doing their work a certain way for many years.

We heard comments and questions such as: “I don’t understand the point of doing this. It’s less convenient.” And even: “Why can’t we chuck this down the drain?” “We made ourselves available to answer any questions and concerns about new ways of working. We found that, as long as we explained the reasoning behind the changes, our colleagues adopted the changes quickly and smoothly,” said Lee.

The benefits we have seen

We can talk about benefits in multiple categories:

• Benefits to the environment

• Benefits to our customers and suppliers

• Benefits to Sterling TT

Reducing waste, energy usage, and carbon emissions from transporting materials, as well as preventing pollution, are the obvious changes to implementing an effective Environmental Management System. Nevertheless, they result in a smaller carbon footprint for our company. A little less greenhouse gas spreads into the atmosphere. Reducing our carbon footprint helps our customers to be more environmentally friendly too.

For customers that integrate social and environmental concerns in their business operations and interactions with their stakeholders, it’s crucial to work with suppliers that take actions to preserve the environment. Customers increasingly ask to fill out questionnaires to understand what we do to improve our environmental performance. By obtaining ISO 14001, we prove to our customers that we are aware of our environmental impact and work on it to reduce it. Also, getting more environmentally friendly is aligned with Sterling TT’s values.

Furthermore, failure to comply with environmental laws can result in significant fines for companies. With an up-to-date legal register and systems in place to respond to changes in the law, we ensure Sterling TT does not get fined and is always compliant with legislation.

Finally, by reducing energy usage, we are saving money, which we can reinvest into our technology and processes, benefiting customers who purchase our heat exchangers or aftersales services.

What next?

So yes, we’ve got the 14001 certification, and that’s a considerable achievement for Sterling TT. We’re very proud of the progress we have made so far. Now our company needs to keep up the good work. Part of the ISO standard says that to maintain certification, you need to show evidence of continuous improvement.

“There’s always new technology coming out, and it’s a case of where we can improve, how we do it, how much it is suitable for Sterling TT, and how quickly we can implement this to improve our environmental performance.” Lee Hatton, Quality & Environmental officer at Sterling TT.

About the company

Sterling TT has been a pioneer in heat exchange innovation since 1904. it designs and manufactures customised heat exchangers. besides, it has a robust aftersales department offering spares, tir (test, inspection, and report), replacements, repairs, overhauls, offshore surveys, and maintenance services of existing heat exchangers. sterling tt, located in the uk, delivers globally.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in March 2023. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.