^ Kinam’s state-of-the-art facility at Navi Mumbai, India.

Article By John Butterfield

___

A brief history of Kinam Engineering Industries

Kinam Engineering Industries was established in 1981 by two brothers Kirit Narbheram Mehta and the late Lalit Narbheram Mehta. The name of the company is, in fact, derived from shortening Kirit’s name: KIrit NArbheram Mehta.

“In the early years, the company operated largely as a fabricator, taking on many engineering jobs such as manufacturing of pressure vessels, columns, tanks, and heat exchangers. However, in the early 1990’s the company shifted its focus completely to the production of shell & tube heat exchangers,” begins Mr. Mehul Mehta, the son of Mr. Kirit Mehta who joined the company in 2001. “One of our biggest clients since inception was Uhde India,” continues Mr. Mehta “and this continues today even after forty years and after the fact that Uhde India has been taken over by ThyssenKrupp to become ThyssenKrupp Industrial Solutions, India.”

“In later years we began carrying out research on enhanced heat transfer tubes, and after studying various corrugation profiles, we developed a new brand – KICC-corrugated tube heat exchangers. Today, we can proudly state that we have installed more than 8500 heat exchangers in various facilities of which more than 2500 are corrugated.” As of 2020, the company employs 200+ personnel. Its headquarters is located in Sion, in the heart of Mumbai, India, and the company has three production facilities one in Mahape, Navi Mumbai and two located in Bhiwandi, on the outskirts of Mumbai. These production facilities cover a total area under crane in excess of 56,000 sq. ft.

State-of-the-art facility

“Our facilities are equipped with state-of-the-art machines like CNC cutting, shell rolling machines with pre-pinching facility, CNC drilling, a hydraulic press for dish end forming, and orbital welding,” continues Mr. Mehta.

“We are able to carry out: hydraulic, pneumatic, vacuum, helium leak, penetrant flow, radiographic, ultrasonic, and PMI testing. We manufacture our heat exchangers in various MOC’s like hastelloy, duplex, super duplex, Inconel, Monel, Cu-Ni alloys & all grades of stainless steel. When welding special metals like titanium and tantalum, we also have a 1000 sq. ft. clean room with a AHU facility to maintain a dust free environment. Our move towards being a state-of-the-art company has therefore been a very conscious one to separate ourselves from the competition. For the same reason we do not outsource critical sub-processes in production because we do not want to compromise on quality, and by keeping them in-house we can keep a tight check on the quality of what is being made, and what procedures are being followed.”

Flagship product – KICC Corrugated Tube Heat Exchangers

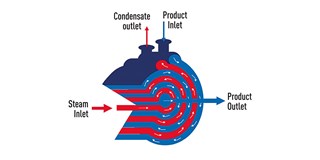

Kinam Engineering Industries specializes in the production of a number of heat exchangers, namely: shell & tube heat exchangers, corrugated tube heat exchangers, heat exchangers in exotic materials, hairpin heat exchangers (removable type), spiral heat exchangers, and multi-effect evaporators. A detailed overview of these products and their capabilities is given on Kinam Engineering’s website at: https://www.kinam.in/ . However, without doubt, the company’s flagship product is its innovative KICC Corrugated Tube Heat Exchanger, which is considerably different from conventional ones.

To display its advantages over the plain tube heat exchanger and develop different corrugation profiles, Kinam has built its own test-rig.

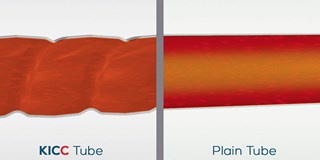

“A corrugated tube heat exchanger is produced by indenting a plain tube in a helical pattern without any thinning of the wall thickness or the development of stresses in the tube. It offers the following advantages:”

Higher heat transfer coefficient

“The helical indentation imparts two flow regimes to the fluid in the corrugated tube: a spiral flow at the core, and eddies at the periphery. As such the corrugated tubes induce turbulence in the fluid even at lower velocities at the peripheral layer. This results in a higher heat transfer coefficient. The two regime flow therefore enables a thorough mixing of the fluid, which ensures a homogenous fluid mass rather than a layered flow pattern. Corrugated tubes hence offer homogenous temperature distribution in the tube.”

Reduced heat transfer area/compact design

“The corrugations, especially in condensing applications, provide a channel to the condensate layer formed on the surface of the tube, which then always provide a fresh new surface for the vapors to condense on. The resulting condensation is consequently drop-wise and not film-wise as in the case with plain tubes.”

“In most condensing applications we are able to reduce heat transfer area by more than 50%.”

Cost saving

“Redustion of size of the equipment has resulted in enormous cost savings over plain tube heat exchangers – in most cases the savings have been between 25–30%. Wherever exotic materials are involved, every square-meter reduction, saves a lot of money, says Mr. Mehta.”

Reduced fouling

“Additionally, the higher peripheral turbulence due to the corrugations prevents any suspended solids from settling on the tubes, which gives it a self-cleaning effect. This leads to a reduction in the amount of fouling, which in turn ensures longer running time without the need to stop for cleaning. Moreover, the response to CIP or mechanical cleaning by a brush/waterjet is much better when compared to a plain tube heat exchanger because of the discontinuous layer of deposition.”

“So in short the corrugated tube heat exchangers are compact, economical in cost, efficient, versatile & offer lower deposition fouling leading to longer running times. These exchangers have lower operating costs, low utility requirements and hence offer quick return on investments,” adds Mr. Mehta.

Process applications for corrugated heat exchangers include heating and cooling, heat recovery, condensation, reboiler, vaporizer, economizer, sub-cooler, intercooler, aftercooler, pre-cooler, preheater, pasteurizer & other such applications.

“We have had over 400 satisfied clients,” says Mr. Mehta “which is very pleasing to say the least. However, this is not unduly surprising because we continually emphasize the necessity for perfectionism within our factories as we require our products to be a guarantee for providing an exacting and long-lasting performance with minimum maintenance. Additionally, we are committed to meeting our agreed upon delivery times, realizing how important it is for our clients to be able to rely on us. In fact these three factors have very much become our traditions at Kinam Engineering Industries.”

“Quality, performance, and committed delivery – A tradition at Kinam.”

Case study

“With one of our customers, who had a leakage problem, the exchanger was beyond repair and we proposed the following solutions:

1st Case: We designed the heat exchanger for our KICC – corrugated tubes, wherein we proposed 45% reduction in heat transfer area and 27% lower cost compared to a plain tube heat exchanger of equivalent heat duty. This directly offered the company a heavy discount on their capital investment.

2nd Case: The customer did not want to change the existing piping, so we suggested to keep the area same and recommended a corrugated tube heat exchanger of the same area as the existing one. This exchanger was more expensive than the former one. Since the corrugations are carried out in-house by Kinam using a special purpose machine, an additional process is added, which increases costs. However, this exchanger could recover 10% extra heat in the process, and the overall saving of fuel/steam was 16%. Due to this the cost of the equipment was recovered within approximately six months.

The client was convinced by our second proposal and accepted it. Today the same customer has replaced all its plain tube heat exchangers with our KICC – corrugated tube heat exchangers.”

What makes Kinam Engineering Industries unique and special?

Kinam Engineering Industries’ strong reputation, founded on the cornerstones of high-quality products, customer satisfaction, and superior service has not been achieved overnight. Rather it has been fostered over years of experience in both manufacturing and in thermal design. Without question, these two factors have led the company to become a leading manufacturer for both shell & tube and corrugated tube heat exchangers.

“When it comes to talking about what makes us special, our team of experienced, in-house designers contributes much to this. Such a team is necessary for any company to be able to produce reliable and innovative tailor-made designs for its customers. Because of this, we provide a very competitive and economical possibility for companies buying these products from Europe and the USA to get their specialized work done.”

“Innovative designs are our core strength”

“Our design team uses reputed software such as that of the Heat Transfer Research Institute (HTRI) for thermal design and software like PV Elite for mechanical design. We have developed our proprietary software ProHE to design Corrugated Tube Heat Exchangers. These are, unquestionably, advantages that many of our competitors do not have,” continues Mr. Mehta.

“Our experience also counts for a lot as well. We have been talking to clients for many years and using their feedback to improve not only our designs but also to advise them with regard to which type of heat exchanger will best suit their needs and budgets. As a result the clients with whom we work have come to trust and rely on our judgements and in this way we have established many long-term relationships. In addition, in recent years, we have concentrated on becoming true heat exchanger specialists.” Undoubtedly, a unique selling point of the company is that it manufactures heat exchangers as small as 1 sq. m2 to as large as 4000 sq. m2 and designs equipment to handle pressure of up to 200 bar.

Kinam Engineering Industries always maintains a stock of raw components so as to be able to quickly start up production orders. Certainly, these factors have helped it to build up a vast array of clients around the world.

Today company customers are found in: Argentina, Indonesia, Egypt, Kazakhstan, Kuwait, Malaysia, Poland, South Africa, Thailand, Turkey, US, Zambia, and obviously India.

Testimonials

It is not surprising that with all this wealth of knowledge and experience in-house, together with the enthusiasm of personnel to perform with excellence, that the company has accumulated many testimonials about its work over the years. Valuable clients include customers such as: Aditya Birla, AsianPaints, Atul, Bayer, ThyssenKrupp, Cipla, Dr. Reddy’s, Jubilant, UPL Ltd and SRF Ltd covering such varied industries as chemicals & petrochemicals, fertilizers, refineries, pharmaceuticals, biotech, edible oil, paper, steel, cosmetics and textiles.

Strategy for the future

Looking to the future, Kinam Engineering Industries wants to further concentrate on expanding its role as a heat exchanger specialist. The company is also evolving the technology to manufacture spiral heat exchangers, which are only produced by a limited number of companies at present and appear to have great potential. Kinam has also developed a new design team to add multi-effect evaporators to its list. Because of its growth plans the company is also looking to expand its production facilities first primarily at home in India but in a few years ahead perhaps abroad as well.

“Finally, we want to find more EPC companies and consultants to work with abroad. In India we work with a lot of these groups but abroad we tend to work only directly with end-users so we will be interested to see where this road could take us to work more intensively on foreign projects.

Equally, we are also open to build strategic partnerships, technical collaborations, and joint ventures with other companies from abroad who are eager to explore the growth opportunities in the Indian market.”

“We have a very strong family-based culture that all our employees are tremendously proud of and by keeping to our traditional values of providing the very best, we believe we have a tremendous future ahead,” concludes Mr Mehta.