Heat energy is critical to the chemical processing industry and heat recovery and reuse are central to the energy management process. Turnbull & Scott design engineers work closely with process engineers from the industry to support this.

By Sam Rippin, Turnbull & Scott

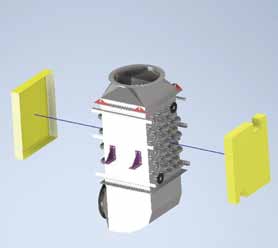

A process engineering team approached Turnbull & Scott to design a thermal fluid economiser to capture and transfer flue gas heat to a thermal oil, replacing an old steam generator. The customer’s goal for the heat exchanger was to raise the heat of the thermal oil from 50°C to 100°C. The customer’s process engineering team were able to provide key data on the flue gas including outlet temperature from the boiler and the flow rate of the thermal oil.

Thermal fluid efficiency challenge

Using T&S’s proprietary research-backed heat exchanger software SCalc™ and their knowledge of the characteristics of thermal fluids, the design engineers determined that 295kW of duty would be required from the flue gas via the economiser to achieve the target 100°C in the thermal oil.

However, it was determined that only 265kW could be made available from the flue gas at its stated temperature and flow rate in order to achieve the energy balance and avoid temperature crossover. This was, unfortunately, 30kW short of the energy required to achieve the thermal oil target temperature. The conundrum was, could the thermal oil conditions i.e. flowrate or temperature be altered to reduce the required duty to 264kW? After considerable investigation it was concluded that the conditions couldn’t be changed, so the customer’s process engineering team went back to the drawing board to consider how else the ‘waste’ process heat could be used.

Resorting to plan B:

After some time, the team were back in touch with plan B. This plan involved recovering flue gas heat into boiler feed water. This proved a straightforward design with the only constraint to be factored in being the limited available physical space, which is not unusual. The goal in plan B was to raise the temperature of the boiler feedwater from 80°C to 170°C. The heat exchanger software SCalc™ set to work and determined that 270kW of heat energy could be recovered and transferred to achieve that goal. The energy savings this boiler feedwater economiser will deliver are not inconsiderable. Assuming a 24/7 operation and a gas price for a large energy consuming plant to be circa 1.6p/kWh, the savings would be as follows:

- 270kW x 1.6p/kWh = 432 pence/kWh (or £4.32/kWh);

- A gas hot water boiler running 24/7 for 50 weeks a year in the chemical plant, forecast savings = £4.32*24*7*50 = £36,288 p.a.

To sum up, this ingenious adaptation not only circumvented spatial constraints but also promised substantial energy savings. SCalc™ predicted a recovery and transfer of 270kW of heat energy, facilitating a remarkable cost-saving opportunity. Considering the operational parameters of a gas hot water boiler over a year, the projected annual savings of £36,288 underscore the tangible benefits of Turnbull & Scott’s innovative approach.

About the author

Sam Rippin joined Turnbull & Scott as Marketing Executive in 2021 and has since been promoted to Marketing Manager. He is responsible for a wide range of marketing activities, including website management, social media, advertising, and market research. Sam specialises in product promotion and has experience launching new products across many different channels.

About this Technical Story

This Technical Story was first published in Heat Exchanger World Magazine in March 2024. To read more Technical Stories and many other articles, subscribe to our print magazine.

Technical Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Technical Story on Heat Exchanger World online and in print.