Working towards improving the sustainability of geothermal energy, the GeoSmart project is working on innovations to improve the flexibility and efficiency of geothermal heat and power systems, thereby making it cost competitive against its fossil-fuel based counterparts.

Text courtesy of TWI, images supplied by Zorlu Energi and CEA

The GeoSmart project is funded by the European Union’s Horizon 2020 research and innovation programme under grant agreement number 818576. GeoSmart kicked-off in June 2019 and is led by a consortium of 19 partners (across UK and Europe) with complimentary expertise including two demonstration sites in Germany and Turkey.

Geothermal challenges and GeoSmart solutions

Amidst the growing challenges of soaring energy prices, geopolitical issues and securing Net Zero for climate sustainability, geothermal energy presents exciting op-portunities by providing a much lower carbon footprint and flexibility as opposed to other resources in the energy mix. Unfortunately, despite the prospects offered, geothermal continues to remain a less preferred renewable alternative due to techno-economic challenges that stems from the aggressive nature of their inherent environments. Currently, geothermal is engineered as “always on” baseload and needs to exhibit a high level of flexibility for dispatchability. In the context of GeoSmart, the consortium is developing innovations that will contribute towards improving the flexibility and efficiency of geothermal heat and power systems via:

a) Thermal energy storages and power block management innovations to provide daily flexibility for “dispatchability”;

b) Integration of flexible Organic Rankine Cycles (ORC) that can cope with variations in needs in the electricity markets and

c) innovations that would help suppliers extract more heat from the brine to help supply more heat during high demands.

These innovations are being designed to be demonstrated in working geothermal plants with different flexibility needs – low enthalpy (Insheim, Germany) and high enthalpy (Kizildere, Turkey).

GeoSmart demonstration

Zorlu Enerji, one of the partners in consortium, is providing the high enthalpy demonstration Kızıldere-II geothermal power plant for the GeoSmart project. Kizildere II (KZD2) geothermal power plant is currently being operated with a very special design that is mostly called as triple flash + binary combined cycle technology in the literature. Geothermal brine, gathered from various production wells, are flashed or separated at three different levels to generate 60 MWe electricity via steam turbines. High pressure (HP) turbine exhaust steam is also utilised to generate 20 MWe more electricity via utilising binary turbines using ORC cycle. KZD2 Geothermal Power Plant has one of the highest capacity in Turkey with 80 MW of installed power and among the most important geothermal power plants in the world. All the electricity is sold via feed-in tariff mechanism. There are 12 production wells in operational conditions. Average temperature and pressure at wellheads are 178°C and 10.65 barg respectively.

Enhanced flexibility through integration of thermal energy storage

GeoSmart innovations for KZD2 includes integration of a latent thermal energy storage that would increase the flexibility of the power plant by storing the heat from the brine after the steam separation. This latent heat storage will use Phase Change Material (PCM) to store the energy as latent heat at an almost constant temperature. During periods with low demand, energy will be stored in the storage to be released at a later stage when the demand is higher. As this approach does not influence the flow condition at the wellhead, critical infrastructures will be unaffected under variable energy generation.

Removal of scaling constraints to allow higher utilisation of energy from geothermal brine

At KZD2 site, the geothermal brine is extracted from deep underground and arrives at the production unit at 165°C and 7.85 bar. It is then expanded through 3 separators to 105°C and 1.4 bar; the steam produced feeds three steam turbine stages and exhausted steam from the HP(high pressure) turbine feeds binary unit heat exchangers (ORC cycle) which are all producing 80 MWe.

The limiting constraint, to fully utilising the thermal energy of the brine, is often the need to reinject geothermal brine at high enough temperature to prevent silica precipitation. One of the objectives of the GeoSmart project is to improve the energetic efficiency of the process, by recovering heat from the brine with a limited scaling effect in the reinjection well, as it would block the whole system.

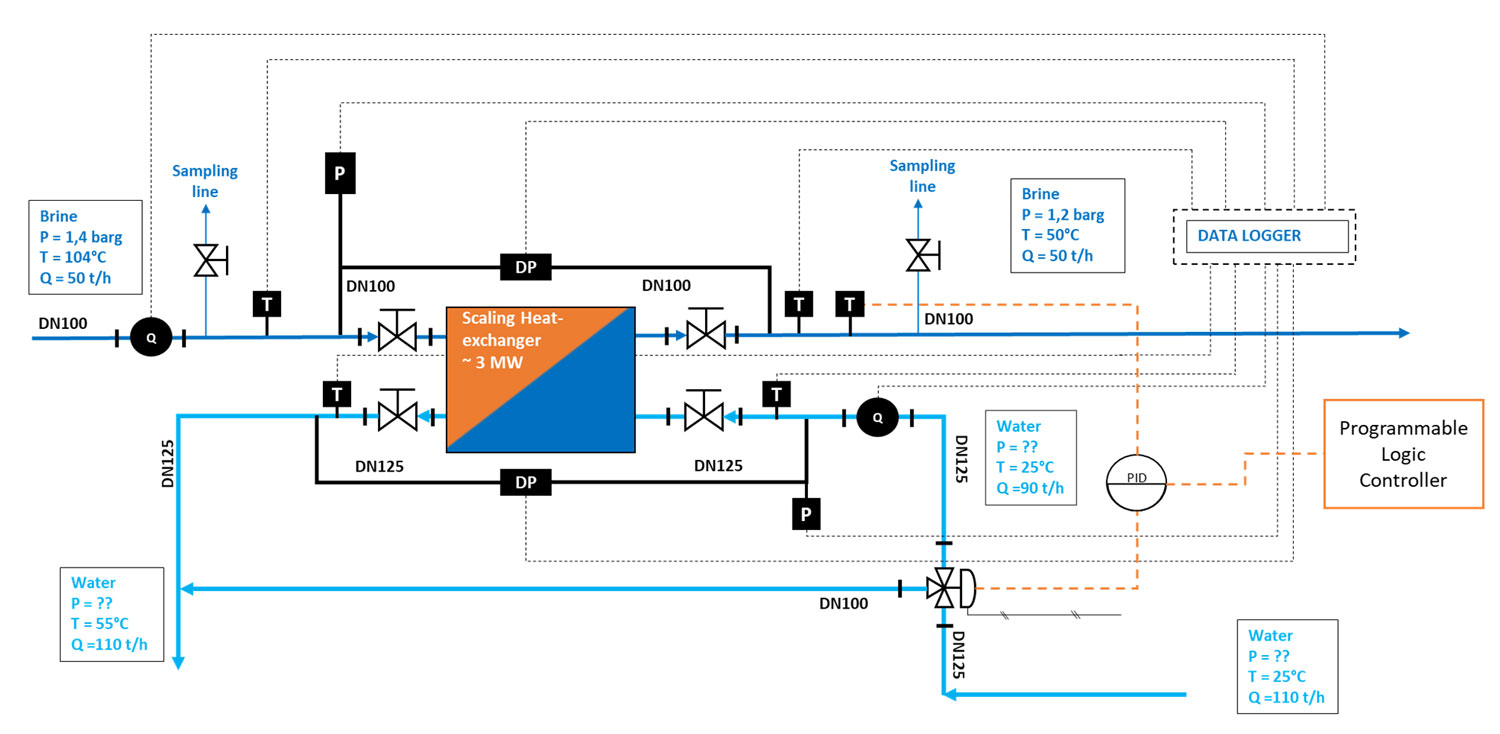

For this purpose, a scaling reduction system has been developed to be installed and tested at the KZD2 site. This system is constituted of three main components including a) a heat exchanger b) scaling reactor and, c) a retention tank. While the heat exchanger has been designed to decrease the temperature of the brine from 105 to 50°C, the scaling reactor will encourage silica scaling (in order to enable mineral extraction) followed by silica polymerisation in the retention tank eventually helping with the prevention of downstream scaling during reinjection.

Design of GeoSmart heat exchanger: Technology choice and specifications

The main challenge during the design the heat exchanger was to ensure its compatibility with the brine conditions at KZD2. The GeoSmart heat exchanger has therefor been designed to ensure a highly efficient exchange that allows rapid cooling of the brine enabling silica deposition only in the retention tank. Additionally, specific instrumentation have been integrated to allow fouling measurements on the heat exchanger.

In contrast to the commonly used shell- and-tube heat exchangers in geothermal power plants, GeoSmart uses plate-type heat exchangers (plate and gaskets heat exchanger with a thermal power of 3 MW) due to its cost efficiency and other advantages specific to our application such as:

• Higher turbulence induced between the plates to keep the fine solid particles in suspension

• Superior surface quality of the plates as compare to the tubes

• Low residence time

• There are a few dead areas where the fluid is almost stagnant

• Easier cleaning of the exchanger by chemical process or by plate disassembly, when manual cleaning is required.

to help understand the heat exchanger design, a simpli-fied scheme of the facilities that is proposed for KZD2 is illustrated in Figure 1

Current status

The project was originally funded for four years and is now due to be completed by September 2024 due to impacts of COVID and other technical challenges. With respect to the demonstrations at the KZD2 site, the design and built of scaling reduction system is now complete. The integration of the system is planned for early next year along with the thermal energy storage system as part of full-scale demonstration of the Geo-Smart system.

GeoSmart consortium

The project is led by TWI as coordinator to ensure project delivery including management of the multi-disciplinary team of 19 collaborators, each providing specialist domain knowledge and expertise to fulfil the project objectives. These include power plant operators like Zorlu Energy and Naturlich Insheim GmbH for hosting the GeoSmart innovations in Turkey and Germany respectively, research and technology organisation like CEA (France) for the design of thermal storages and Heat exchangers supported by NALDEO (France) and Fraunhofer (Germany), and engineering firms like SPIKE Renewlables (Italy) for the design and build of the scaling reduction system. Other key partners include VITO (Belgium), EGEC (Belgium), ON power (Iceland), METU (Turkey), Gerosion (iceland), Kadir Has Uni-versity (Turkey), TVS (UK), FPS (Norway), COSVIG

(Italy), PVALD (Iceland), ICETEC (Iceland), University of Iceland (Iceland).

About the project

For more information about the GeoSmart project, go to the website: https://www. geosmartproject.eu/

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in November 2022. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.