HVAC ducts are used to convey air within buildings and can become unclean and unsanitary over time, requiring the services of a specialist team or company to rectify. Ductwork can be complex in size, shape and direction, and the most optimal way to clean ducts is the use of a high-tech robot.

By Craig J R Thomas, JettyRobot Ambassador, HVAC/R Coating Specialist & Senior Managing Consultant – The Pipe-Sol Consultancy Ltd

A duct is a conduit (pipe, passage or tube) by which air is delivered and/or removed in heating, ventilation, and air conditioning (HVAC) systems. A system of ducts in a residential or institutional building or an industrial or commercial unit is called ductwork. Today’s ductwork can find its origins in China and Greece in the 7th century, when a system of chimneys and flues were used to convey heated air into buildings whilst keeping them free of smoke. Ducts can be found everywhere from super yachts to sky scrapers, hotels to hospitals, oil refineries to oil rigs. Onshore, offshore. From privately owned buildings to government controlled infrastructure. Ducts can be circular-, rectangular- or square-shaped ranging from approximately 2.5 inches (63.5 mm) in diameter for circular ducts to over 48 inches (1,220 mm). Duct diameter/sizes will obviously vary with shape, and what local/regional regulatory and insurance standards will permit.

Clean ducts, improved air quality, better performance

Over time, ductwork can become dirty, blocked or contaminated to the point that may result in poor air quality, compromised heat exchange or fume extraction, and inefficient HVAC unit operation. Dust, grease and other particulates can also be flammable. What is the solution? All ducts should be regularly inspected and cleaned, with many now being disinfected more frequently and aggressively since the Coronavirus Pandemic of 2020/21.

There is very little information in the public domain regarding the history of duct cleaning – its origins and the methods traditionally used. What is known is that the creation of HVAC systems lead to the implementation and birth of an industry responsible for duct cleaning, and this industry has simply grown and grown. The relationship of these two integral parts of ultimately one industry is symbiotic.

In a report prepared for the US Environmental Protection Agency (EPA) published in 2005, it was estimated that the air duct cleaning in the United States generates revenues of USD 4.0 billion annually and that the cost of commercial and institutional building remediation to improve Indoor Air Quality (primarily for HVAC systems) amounted to USD 2.9 billion per year. At this time, the split between residential and commercial air duct cleaning was 1:31. If it is assumed that the US market represents ca. 40% of the global market, taking into account inflation and using the same split, this means that the global revenues from air duct cleaning in 2022 are in the region of USD 16.1 billion per annum with USD 12.1 billion being generated from the commercial market.

When plans for modern residential/commercial buildings and industrial facilities are drawn up, ongoing maintenance of HVAC systems is always a design and operational consideration. With this in mind, ducts are normally installed in sections with access panels.

Ductwork can be manually cleaned, sometimes even requiring an expertly trained technician to enter the ventilation duct under strictly controlled supervision. Mechanical tools may be employed to assist the technician carry out duct cleaning and maintenance. Specialist companies tend to be employed to clean and maintain the ductwork in hospitals and hotels, airports and prisons, pharmaceutical concerns, sewerage treatment works and power stations as well as oil & gas and marine installations. The two most common ways to clean ducts are use of a pressurised “air hose/air whip” or “rotary brush” and a high-powered vacuum cleaner. These techniques require the ductwork to be constructed in sealed sections with access panels at either end. During the cleaning process, the ducts are normally placed under negative pressure so that dust and dirt is prevented from escaping.

Robotic duct cleaning technology

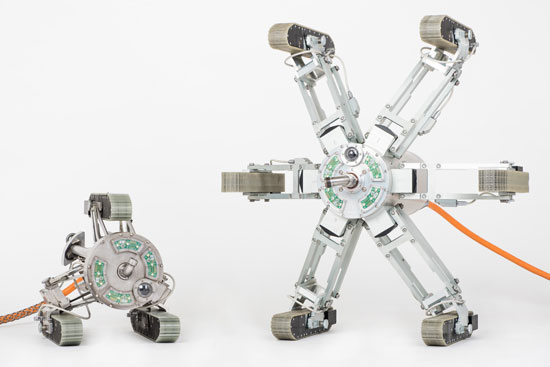

A newer, more innovative technique is the use of a robot to carry out the critical HVAC maintenance task of duct cleaning. A robot can typically be purchased directly from the technology equipment supplier or rented so that the HVAC maintenance service, building or facilities management companies can carry out the work themselves or a robotic duct cleaning service can typically be provided by the same robot technology equipment provider. Such a company is JettyRobot based in Prague, Czech Republic. JettyRobot is a company dedicated to and specialised in the development of robots working in HVAC duct and pipe environments.

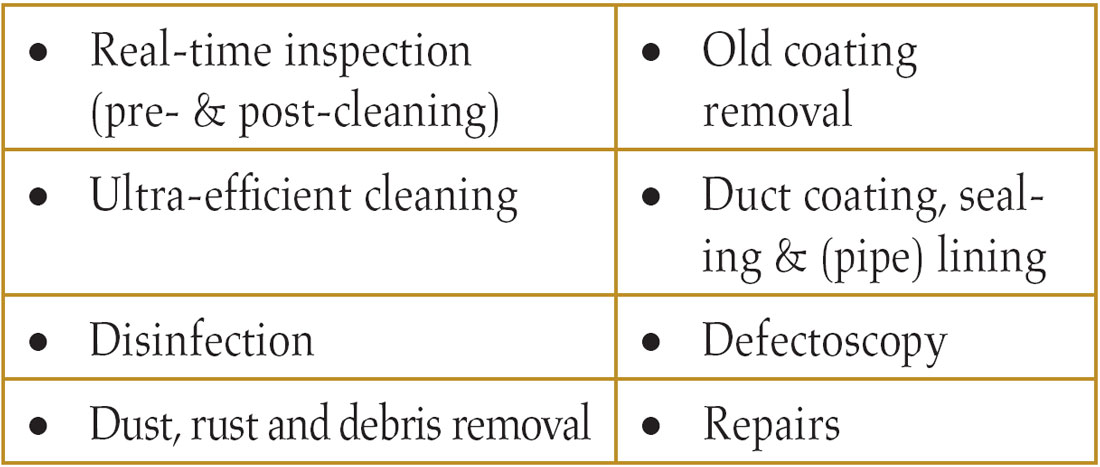

A specialised robot can carry out a wide range of complex tasks:

Robots were originally developed to clean HVAC ducts. They can also be employed to clean industrial exhausts in a multitude of different industries and environments, such as:

Pipes operating in the power generation, Oil & Gas as well as waste water industries can also be inspected, cleaned (even abrasive blast cleaned) and recoated using robot technology. Industrial exhausts and pipes will not be discussed in detail in this article. The focus shall be HVAC ducts.

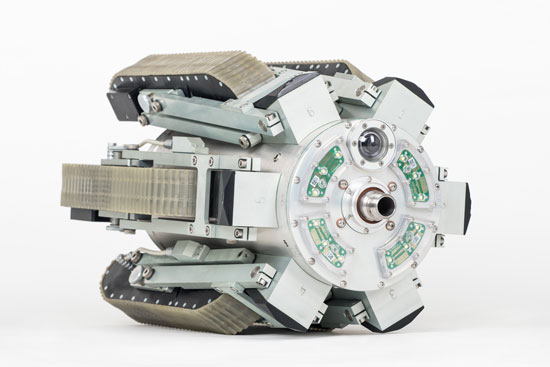

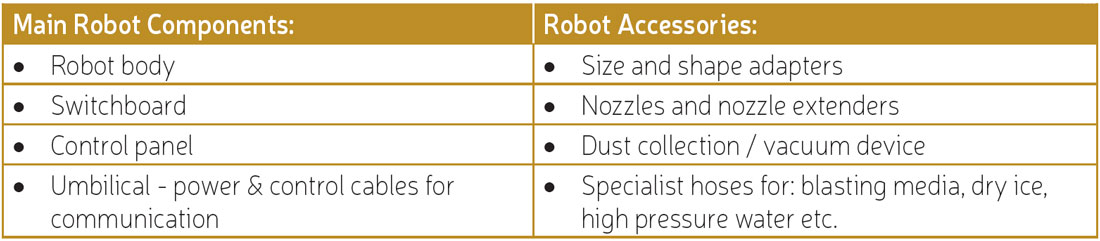

The robots used in HVAC duct cleaning are characterised by having a number of common components (see table 1). They can then be modified for the specific task or project through a series of accessories, however is it self-evident that not all robots are created equal.

The quality of design and manufacture as well as robotic functionality and ‘operational agility’ allow the ultimate user of this state-of-the-art technology to differentiate between devices and select the best robot for their project. A uniquely designed belt robot based on space technology will clean air conditioning ducts, commercial kitchen and industrial vents, and in fact any spaces where cleaning is arduous or impossible without dismantling of the ductwork with an extremely high degree of efficiency and effectiveness. These robots offer many advantages compared to traditional duct cleaning methods and even to standard robotic cleaning technology.

JettyRobot advantages:

• Quick set-up – compact, modular design

• Easy operation at a distance – using a control panel and 100-metre-long umbilical (328 ft)

• High torque pulling force (power) and excellent manoeuvrability in tight spaces

• HD camera-recorded cleaning process – front and rear

• Environment-friendly cleaning process using dry ice – possible to clean without aggressive chemicals

• Efficient release of contamination using state-of-the-art technology

• Gentle cleaning processing and low service weight device – no damage to ductwork

• Disinfection of ducts possible

• Rotary brush tool still available as well as vacuum device

• Accessories can be custom-designed and added as required – pneumatic scraper, UVC-light wand

• Stability in service

• Suitability for all duct shapes

Two of the above-mentioned advantages worthy of more detail are the robots’ stability in service and their suitability for all duct shapes. JettyRobots are centred in and “propped” (pneumatically locked) against the side of the duct, generating sufficient stability to even allow for the use of high pressure cleaning methods. The JettyRobots’ multi-tracked body allows it to expand (under pneumatic pressure) to the required size of the duct and easily pass through, inspect and clean circular, rectangular or square-shaped ducts in both horizontal and vertical planes; they can also handle slopes, as well as negotiate S-shaped ducting and various turns. These specialised robots offer great safety (technicians do not have to enter dangerous areas removing the need for confined space working), and greater accessibility (the whole system is cleaned, even areas normally inaccessible to maintenance personnel). They also improve efficiency as robotic cleaning is faster and more effective than manual cleaning, generating additional labour and operational cost savings. Use of dry ice means that the risk of leaks during cleaning normally associated with chemical solutions or water is reduced to zero; HVAC ducts are not normally sealed. There is also no need to remove the contaminated water. The ductwork does not require disassembly – the risk of suspended ducts falling and injuring personnel or damaging equipment during disassembly is removed. Sick Building Syndrome (SBS) may also be eliminated with ducts that have been cleaned and disinfected to the very highest standards by space-age robotic technology.

Inadequate duct cleaning & SBS

SBS (Sick Building Syndrome) is defined by the US EPA as “situations in which building occupants experience acute health and comfort effects that appear to be linked to time spent in a building, but no specific illness or cause can be identified. The complaints may be localized in a particular room or zone, or may be widespread throughout the building.”2 Symptoms usually disappear in the occupant soon after leaving the building.

The following have been cited by the EPA and multiple other parties as causes of or contributing factors to SBS, and all relate to ‘duct’ cleaning: inadequate ventilation, chemical contaminants from indoor sources (requiring extraction via fully operational and effective exhaust systems), and biological contaminants (bacteria, moulds, and viruses). Even after a thorough building investigation, the specific causes of SBS may remain unknown.

Numerous studies by government and environmental health specialists have shown Indoor Air Quality (IAQ) to be a significant environmental threat to human health. A report issued on a World Health Organisation (WHO) meeting in 1984, which continues to be quoted in the industry today, suggested that 30% of new and remodelled buildings worldwide could be the subject of excessive IAQ-related complaints3 with the SBS frequency varying from country to country, region to region. Many energy-efficient buildings with airtight envelopes seem to develop SBS, particularly those that operate large ventilation/air conditioning systems. Ineffective cleaning or non-maintenance of a building’s or industrial unit’s HVAC system and ducts may result in inadequate ventilation, poor IAQ, and can lead to SBS. Dark, damp and dirty ducts can result in the concealed growth of bacteria, moulds and fungi. Unclean and poorly maintained ducts provide the ideal breeding ground for pathogens, as dust and particulates that coat the internal surfaces of HVAC duct-work support their growth. Mould, mildew and other fungi spores reproduce, become airborne and are passed through the HVAC system and therefore throughout a building.

“When symptoms of diagnosable illness are identified and can be attributed directly to airborne building contaminants,”2 the EPA defines this as a Building Related Illness (BRI). An example is Legionella infection. In contrast to SBS, BRI’s are less common, but may result in significant morbidity.

BRIs, dirty ducts and Legionnaires’ disease

Poor and stagnant air caused by a dirty and inefficient HVAC system as well stagnant, standing water that has accumulated in ducts and drain pans can cause bacteria and viruses to form or those already living in the air ducts to thrive, circulate and cause infection more easily. In a worst case scenario, certain bacteria such as Legionella can form, be transported on air droplets through ventilation ducts and into an office worker or resident’s lungs causing serious harm or even death, especially to those with weakened immune systems. The bacterium Legionella pneumophila was first discovered six months after an outbreak in July 1976 in a group of people, who attended the 58th convention of the American Legion in Philadelphia, USA. Those that were affected suffered from a type of pneumonia that is now known as Legionnaires’ disease. According to the World Health Organisation (WHO), Centers for Disease Control & Prevention (CDC), The Lancet and many other institutions.4,5,6,7 Legionella has been associated with other outbreaks of Legionnaires’ disease linked to poorly maintained artificial water systems since 1977. Sources of aerosolised water droplets that have been linked with the transmission of Legionella bacteria include air conditioning cooling towers, evaporator and condenser coils, and other hot and cold water systems.

The CDC concluded that “Legionella pneumophila (…) was spread through the (Bellevue Stratford) hotel’s air conditioning system”8. To this day, experts cannot be sure of the exact source of the Legionnaires’ disease outbreak at this hotel in Philadelphia. It is conjectured that the Legionella bacterium had colonised the hotel’s cooling towers, however by 1977 when Legionella was finally identified, the hotel’s cooling towers had been cleaned, so a critical piece of evidence was not available to CDC investigators. Over the last 40 plus years, cooling towers have been identified to be the source of other Legionnaires’ disease outbreaks.

The Lancet summarises very well a key lesson learned:

“Until 1976 no one had suspected that airconditioning systems and cooling towers could pose a pathogenic threat to occupants of luxury hotels (and other buildings). In other words, the epidemic was very much the product of modern technology and the built urban environment.”6 Cleaning the internal surfaces of ductwork can often be overlooked as a building maintenance task, but its importance should not be undermined. According to the WHO, “special consideration should be given to the ventilation system, including air take, the humidifier system, (…) contamination of ducts, and to the(ir) standard of cleanliness.”3 Levin also identified that one the main categories for “IAQ problem prevention or mitigation” is air duct cleaning.1

JettyRobot s.r.o.

Development of the first JettyRobot began in 2008 working in cooperation with the Czech Technical University, and was launched in 2009. The tech start-up was bought by an investor in 2017 due to the foreseen potential and need from the market, and a new company JettyRobot s.r.o. was established. The company now offers two robots based on the size of duct to be cleaned and the type of cleaning required – JettyRobot 6 and JettyRobot S, each of which has evolved following the acquisition of experience and operational knowledge from the field. JettyRobot 6 is 6th generation and the new smaller “S” is 3rd generation technology. JettyRobot is one of the leading robotic duct cleaning technologies in the world.

Conclusion

In order to remediate and prevent IAQ issues in residential, commercial, industrial and institutional buildings caused by dirty, blocked or contaminated HVAC installations, air handling and extract ventilation (exhaust) systems, it can be strongly argued that ductwork should be regularly inspected and cleaned. The best, most efficient and effective way to carry out this critical maintenance task is by specialised robot. Duct cleaning by robot also reduces health, safety and fire risk and will maintain or improve HVAC system performance; more important than ever in a world threatened by rising energy costs. It should also be noted that research into IAQ and HVAC duct cleaning continues 45 years after the 1976 Legionnaires’ disease outbreak. Education and communication are also pivotal elements of any remediation and prevention strategy to maintain the heath and function of a building’s lungs, and so I publish this article.

About the author

Craig is Jetty-Robot Ambassador for the UK, UAE and Malaysia. He set up his own international

Craig is Jetty-Robot Ambassador for the UK, UAE and Malaysia. He set up his own international

consultancy business in 2016, focusing most recently on HVAC/R market. He has over 20 years’ experience in the field of coatings in the O&G and water industries, and has worked with/for 3M, Copon-E Wood, Jotun, Kansai Paint, and Heresite. He is a certified NACE Coating Inspector (Level 1) and an ASHRAE Associate Member.

References

1. LEVIN, H., “National Expenditures for IAQ Problem Prevention or Mitigation”, Lawrence Berkeley National Laboratory, June 2005 (Study prepared for US Environmental Protection Agency).

2. “Indoor Air Facts No. 4 (revised) Sick Building Syndrome”, United States Environmental Protection Agency, February 1991.

3. “Indoor air quality research”, Report on a WHO Meeting, Stockholm, 27-31 August 1984, World Health Organisation, Regional Office for Europe, 1986.

4. “Legionellosis”, Word Health Organisation, https://www.who.int/newsoom/factsheets/detail/legionellosis, Accessed: 1 October 2022.

5. “Developing a Water Management Program to Reduce Legionella Growth & Spread in Buildings”, Centers for Disease Control & Prevention, https://www.cdc.gov/legionella/downloads/toolkit.pdf, Accessed: 1 October 2022.

6. HONIGSBAUM, M., “Perspectives. The art of medicine. Legionnaires’

disease: revisiting the puzzle of the century”, The Lancet, Vol 388, Issue 10043, P456-457, 30 July 2016.

7. WINN, W. C., JR, “Legionnaires Disease: Historical Perspective”, Clinical Microbiology Reviews, January 1988, P60-81, Abstract provided by National Center for Biotechnology Information

(NCBI), https://www.ncbi.nlm.nih.gov/pmc/articles/PMC358030, Accessed: 1 October 2022.

8. “Legionnaires’ Disease”, Centers for Disease Control & Prevention, https://www.cdc.gov/ Accessed: 2 October 2022.