Within the transport sector, and encompassing the automotive, aerospace, naval and defence sectors, there is currently a strong drive towards Net Zero, increased efficiency, light-weighting and miniaturisation. However, heat exchanger technology that meets these goals exists in the form of printed circuit heat exchangers (PCHEs), where a stack of machined or photo-chemically etched shims are stacked and joined together using the diffusion bonding (DB) process. Such devices are commonly made from ferrous and nickel-based alloys and the ability to make these out of lower-density alloys, such as aluminium alloys, will be highly advantageous.

TWI is embarking on an innovative research and development project, funded under TWI’s Exploratory Programme, to further develop Al-alloy PCHEs, using Al-6082 as a demonstration case. By developing these, TWI will be able to help fulfil an industrial need.

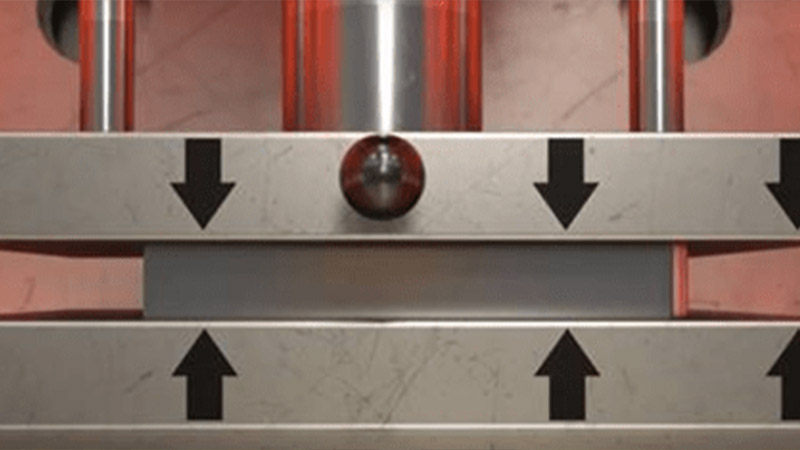

The initial phase will involve the design of a simplified, scaled-down but representative PCHE demonstrator. The TWI team will then work with an industrial partner to develop and procure the photochemically etched shims required for the diffusion bonding trials and then carry out diffusion bonding trials to develop the process parameters, assessed using tensile testing and metallography.