Acoustic Pulse Reflectometry (APR) has been applied extensively to tubular systems in research laboratories, for purposes of measuring input impedance, bore reconstruction, and fault detection. Industrial applications have been mentioned in the literature, though they have not been widely implemented. Academic APR systems are extremely bulky, often employing sophisticated set up, which limits their industrial use severely. Furthermore, leak detection methods described in the literature are based on indirect methods, by carrying out bore reconstruction and finding discrepancies between the expected and reconstructed bore.

By Mr. Vignesh Sivanandam, Talcyon Pte. Ltd.

Here, we describe an APR system (named APRIS) which has been designed specifically for detecting faults commonly found in industrial tube systems such as heat exchangers, condensers and boilers. Faults include leaks, increase in internal diameter caused by wall thinning, and constrictions by blockages or deposits or scales. The system employs hardware setup, making it extremely portable, but creating a large degree of overlap between forward and backward propagating waves in the system. A series of patented algorithmic in-novations enable the system to perform the wave separation mathematically, and then identify the above faults automatically, with a measurement time around 10 seconds per tube.

Fabrication of heat exchangers

Heat exchangers play a vital role in cooling and heating by transferring heat between fluids at different temperature. A solid wall in the heat exchanger separates the flowing fluids. The transfer of heat from hot fluid to the wall is by convection, via wall by conduction and from wall to cold fluid by convection. Such heat exchangers are widely used in chemical plants, petrochemical plants, power generation, food processing plants, HVAC, oil & gas processing plants. Design, fabrication, and testing are the key aspects of heat exchangers prior to its installation at the site premises. Though there are different types of heat exchanger, its selection is based on heat transfer rate, heat transfer coefficient, heat transfer surface area. Design is based on analyzing the application, identifying the fluid properties, energy balance, geometry, thermal calculation, noise, vibration, standards, environmental conditions etc. Fabrication involves drilling, cutting, forming, rolling, welding, expansion, painting etc. When the final stage is reached which is inspection, the most used methodology is hydrotesting to find out leaks. But, would that testing alone suffice the requirement of end users?

Acoustic Pulse Reflectometry Inspection System

Preventive to predictive maintenance requires more data and rigorous inspection. Such data points are obtained via multiple testing techniques, but the Acoustic Pulse Reflectometry Inspection System (APRIS) is the fastest, reliable, and most intuitive to meet the requirements.

APRIS works on the Acoustic Pulse Reflectometry (APR) principle. An acoustic pulse injected into a semi-infinite straight walled tube will propagate down the tube without generating any reflections. This pulse can be measured by mounting small microphone(s) with its front surface flush with the internal tube wall, through a hole in this wall. The microphone will measure the pulse once only, as it passes over the microphone diaphragm.

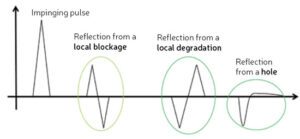

If, however, the pulse encounters a discontinuity in cross section, a reflection is created. The amplitude and form of the reflection is determined by the characteristics of the discontinuity: a constriction will create a positive reflection, whereas a dilation (increase in cross section) will create a negative reflection. Neither of these discontinuities will change the shape of the pulse in their vicinity, but the reflection measured by the microphone will be an attenuated and smeared replica of the impinging pulse, due to propagation losses.

A hole/leak in the tube wall, on the other hand, will create a reflection having a more complicated shape, affected by the size of the hole and the radiation of acoustic energy to the space outside the tube. Schematic examples of these cases are presented in Figure 1.

Though some of the acoustic energy present in the original pulse is reflected at discontinuities, some of this energy continues to propagate down the tube. Any further discontinuities will once again create reflections. Therefore, diagnosing the internal condition of the tube is a matter of correctly interpreting the reflections as they arrive back to the microphones. One aspect of the interpretation is straightforward: the time of arrival of a reflection can be used to calculate the precise location of the discontinuity, since such reflections propagate at the speed of sound. The second aspect of interpretation is more complicated, as it involves inferring the exact nature of the discontinuity from the detailed shape of the reflection.

Case study: APRIS on newly fabricated heat exchanger

The end user would like to know if there are any imperfections on the tubes due to expansion and welding performed during the fabrication.

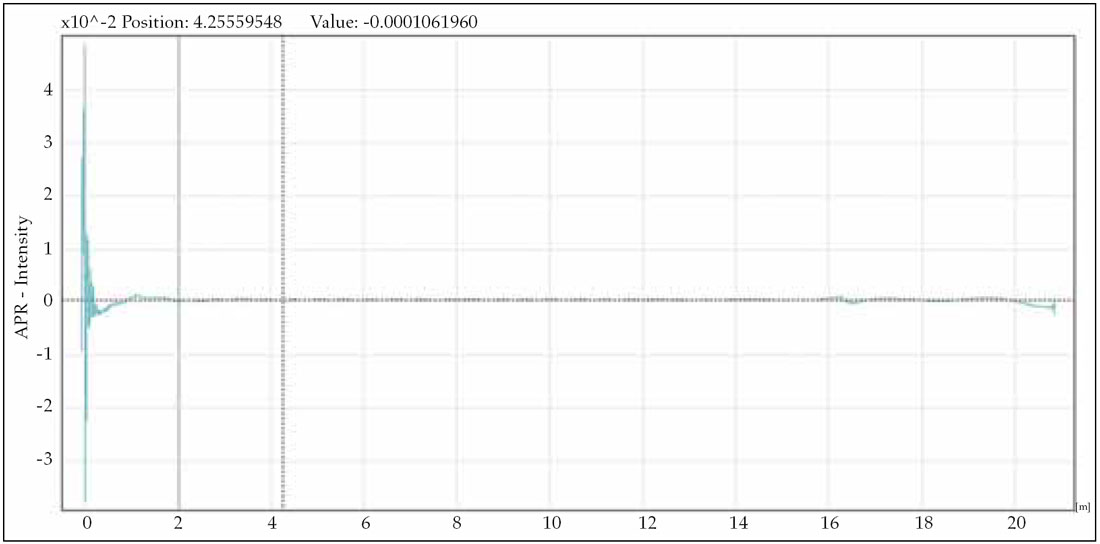

APRIS was applied on this newly commissioned U tube bundle. 291 U-tubes were inspected in less than 1 hour as its not essential to inspect on both top and bottom. The sound propagates from top till bottom of the U-tube. This saved 50% of time against deploying conventional tube testing techniques. Once data was collected for 291 U-tubes, it was processed, and report was presented to end user in 2 hours. Below is the defect map for U tube bundle.

The client was totally surprised to see few tubes in yellow color which indicates a blockage, despite the tubes having been cleaned.

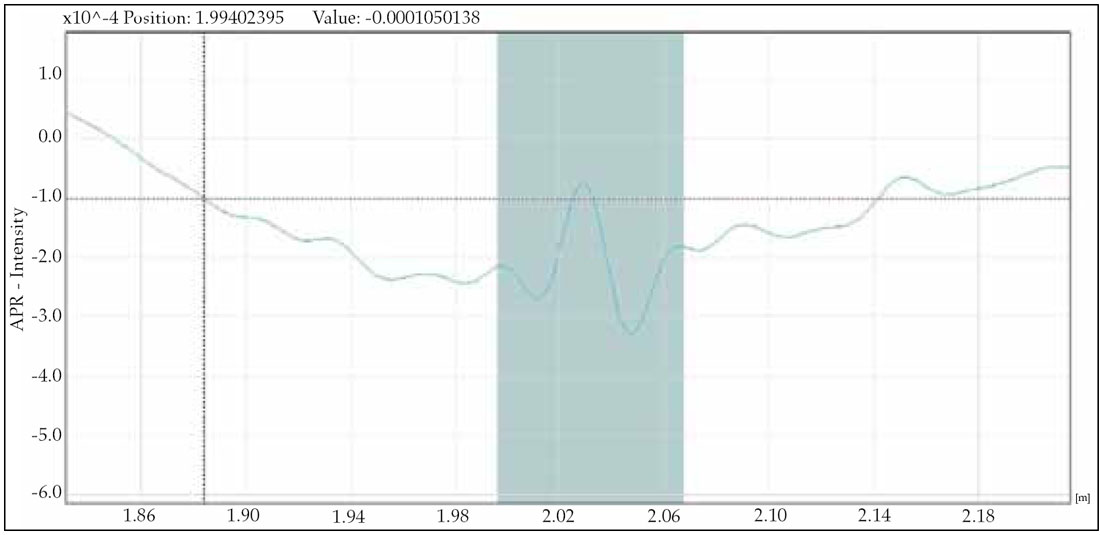

As per APRIS reporting terminology, blockage doesn’t mean that the tube is fully blocked/clogged. If there’s any cross-section reduction in the tube, it will be reported as a blockage with its precise location or spread and percentage of cross section reduction determines the extent of severity.

What does this blockage mean?

Whatever it is obstructing the propagation of sound waves, it gets reflected. Based on the signature, the defect type is determined. By doing the root cause analysis, the end user found that blockage is due to weld imperfection and the report says it is 2% cross section reduction. This helped the end user to understand the sensitivity, probability of detection (PoD), and accuracy on indicating the position and size.

Upon completion of this heat exchanger inspection, the client decided to use APRIS for all of their newly fabricated heat exchangers. In the span of 4 months, 16 newly commissioned heat exchangers were tested to identify the abnormalities in the tube due to welding imperfection, tube expansion, rolling and other defects. This data shall be used as a base line when they do the inspection after completing a few years of service. A complete confidence in maintenance is being achieved by choosing the right technologies.

About the author

Mr Vignesh is an APRIS specialist at Talcyon. He has more than 12 years experience in APRIS technology, data analysis, inspection management of heat exchangers, condensers, and boilers, serving clients globally.

Talcyon is a pioneer in developing the Acoustic Pulse Reflectometry (APR) technology, an advanced ndt solution for inspection of tubes. the company also holds the patents to the technology. the main goal of its products is to make inspection simpler and smarter. Talcyon serves industries such as oil and gas, chemical, power generation, marine, HvAc, petrochemical, food & beverage and paper & pulp.

About this Featured Story

This Featured Story was first published in Heat Exchanger World Magazine in July 2022. To read more Featured Stories and many other articles, subscribe to our print magazine.

Featured Stories are regularly shared with our Heat Exchanger World community. Join us and share your own Featured Story on Heat Exchanger World online and in print.