SACOME has been awarded by one of the most important multinational corporations in the pulp and paper industry with a contract for the supplying of a heat exchanger intended for the heat recovery in their thermomechanical pulp (TMP) production process.

As part of their paper production process, the pulp mill is rinsed with water and, at a later stage, it must be discharged to the biological treatment plant. As reported by the client, in the event that the temperature exceeds 50 °C, the biological organisms consumption can rise considerably due to a loss in efficiency.

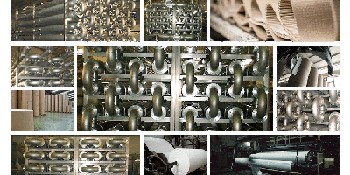

Having assessed different alternatives, we recommended the client one of the configurations within the SACOME Industrial Line, we are referring to our I-TF20-I heat exchanger. This tubular heat exchanger consists of 2 concentrical tubes, in which the effluent, that can have large-size particles, flows through the inner tube, whilst the service water is processed in the annular space.